Special aBlogtoWatch Content For Bulgari

Special aBlogtoWatch Content For Bulgari

When we talk about watches, there is such a large number and wide variety of components to consider — however, the case actually is one of very few components of a timepiece we actually touch, feel, and interact with. A lesser-known fact is that while watch movements do seem to take most of the credit when it comes to complexity and precision in execution, high quality watch cases of today are manufactured with comparable, or even exactly the same tolerances as are movement components – we are talking about 3-5 microns of tolerance in execution. That is the kind of work Bulgari does at its in-house case manufacture in Saignelégier, Switzerland.

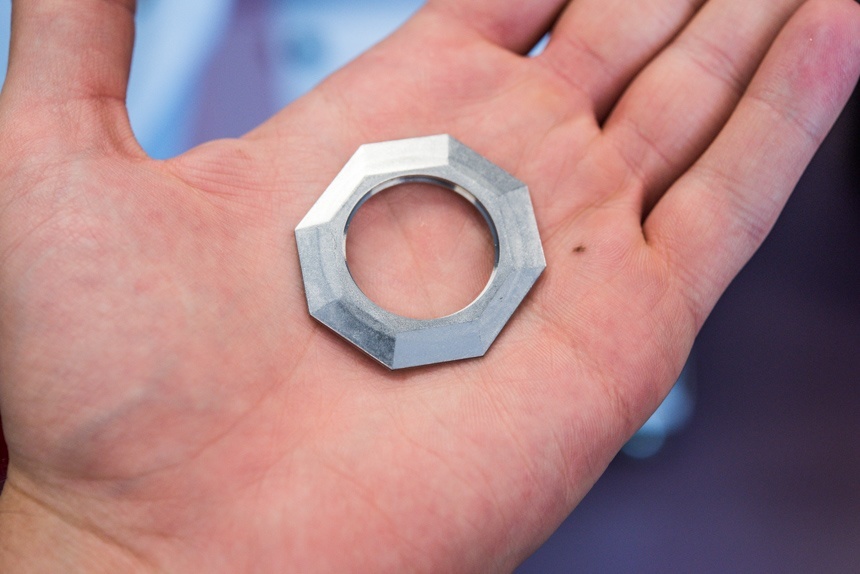

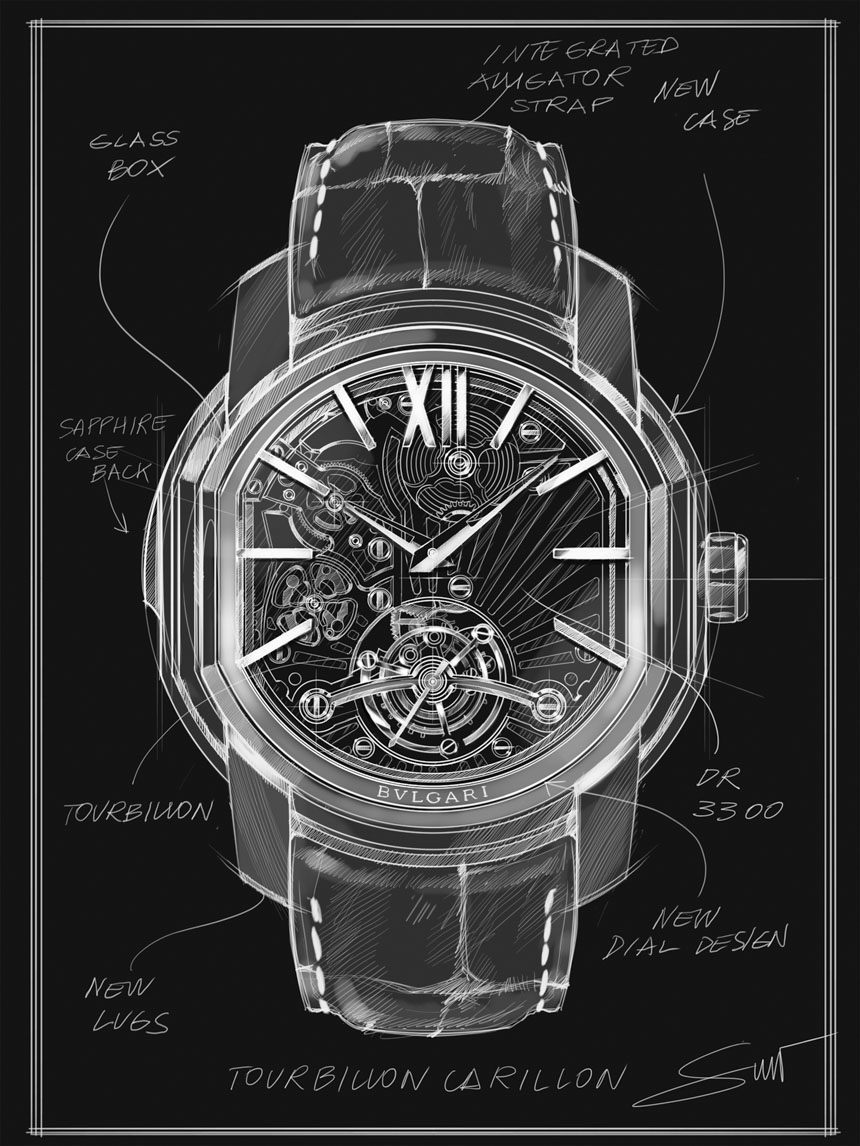

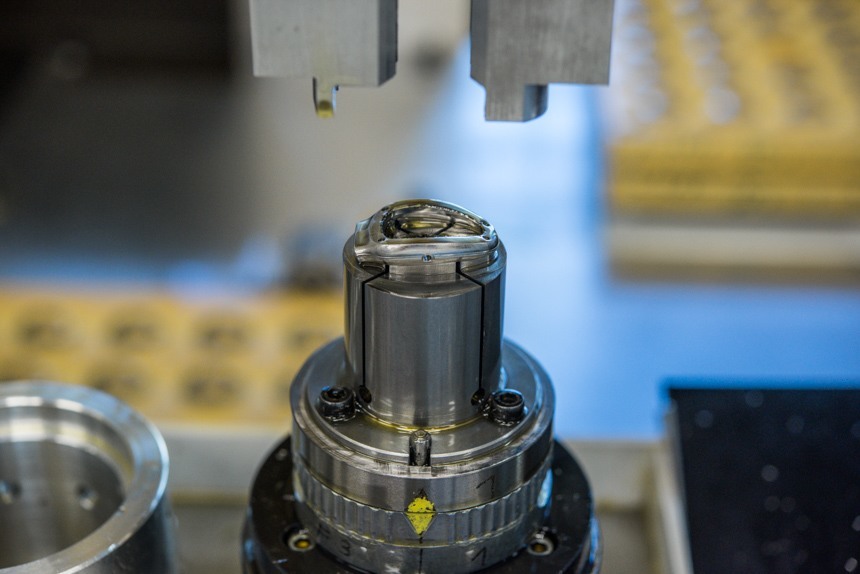

A Bulgari Octo case light years away from completion – and yet already reminiscent of its trademark shape.

The thing is that watch movements can be hidden under solid casebacks, and the average watch lover or wearer will never find out if, well, let’s just say efforts have been anything less than meticulous. On the other hand, cases can be and always are scrutinized, if something is not assembled, decorated, or designed properly, it will be noticed sooner or later – and such mistakes and shortcomings can be deal-breakers even for non-expert buyers.

Cases must not only function properly – as in remain water tight, put up with and protect the movement from knocks, temperature changes, humidity, and other elements – but also look and feel perfect. That is a lot to ask and a huge challenge to overcome, and we are discussing them in detail now because so often their qualities are taken for granted.

This explains why so many of the industry’s famed names still outsource the production of their cases (as well as dials – which we discussed here) and why it takes extremely expensive machinery and a well-trained staff of engineers, CNC operators, assemblers and polishers to manufacture high-quality cases any luxury brand would feel confident in putting their name on.

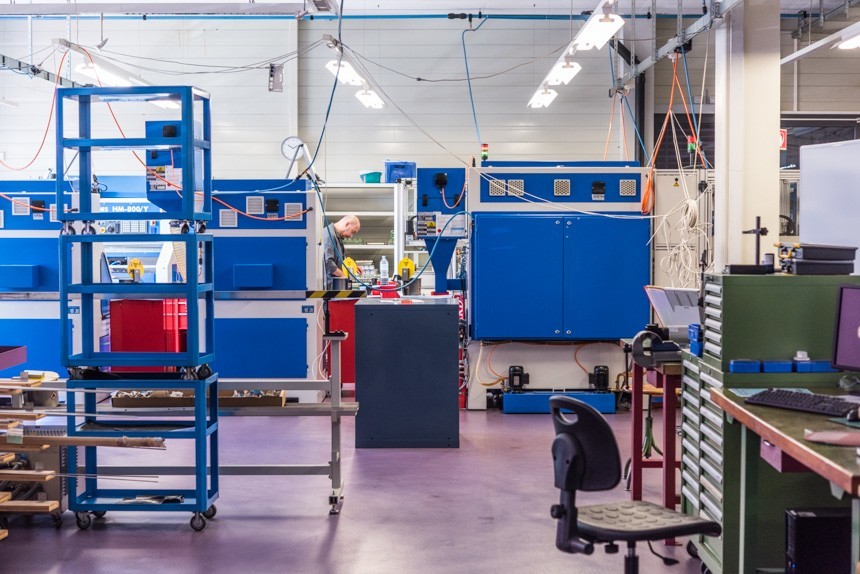

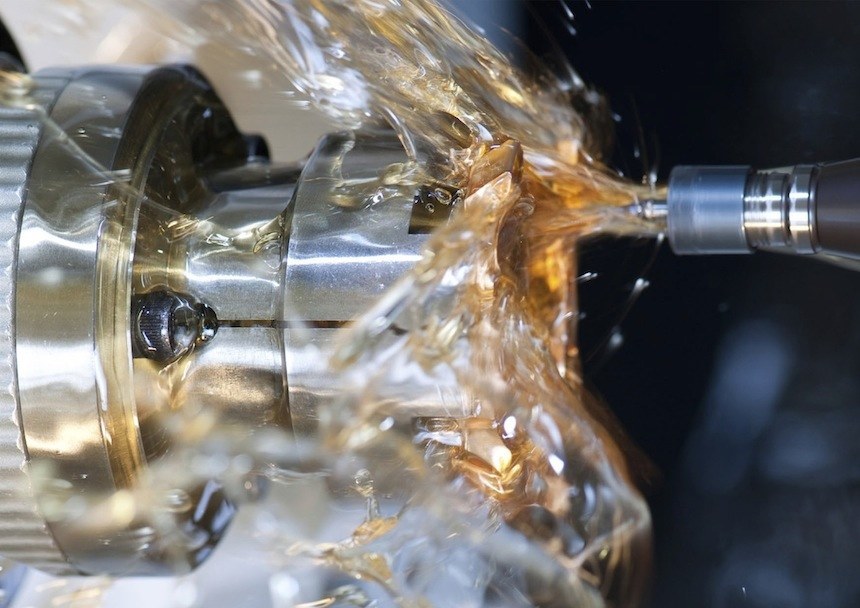

The manufacturing processes for watch cases can differ based primarily on the complexity of the design, the materials used, the number of produced pieces, the knowhow, and the level of automation of the manufacture. In essence, watch cases are either first stamped to create the rough shape and then further refined with a seemingly endless number of CNC cuts, or indeed produced exclusively with CNC, without the first stamping step.

The point is that CNC machines are pretty much always used for watch cases today – machines with five or more axes of movements and with extremely precise drill heads are capable of producing the remarkably complex shapes of today’s cases. What is more is that they can rotate the case and drill all the holes and threads for the crown, pushers, movement holders and other parts with the required precision of around 5 microns (that is about 1/20th of the average thickness of a human hair).

Cases, like all other components, are rigorously checked for quality and precision of execution, and the ones that fall short after any production process, are discarded – like the ones in this box, excluding the Octo, of course!

“Blasphemy!” you may feel inclined to shout, rightfully asking “Where is the human element in the production?” Well, before we jump to case finishing, we’ll say that the machines are not only maintained, but indeed programmed, operated, and checked by the trained staff of the manufacture. Also, all produced pieces are checked after all major production steps to ensure that no faulty pieces – should any come out as such – proceed through the chain of processes, and of course also to prevent the production of larger batches of sub-par components. Needless to say, all of this is performed by experts at the respective step of the production.

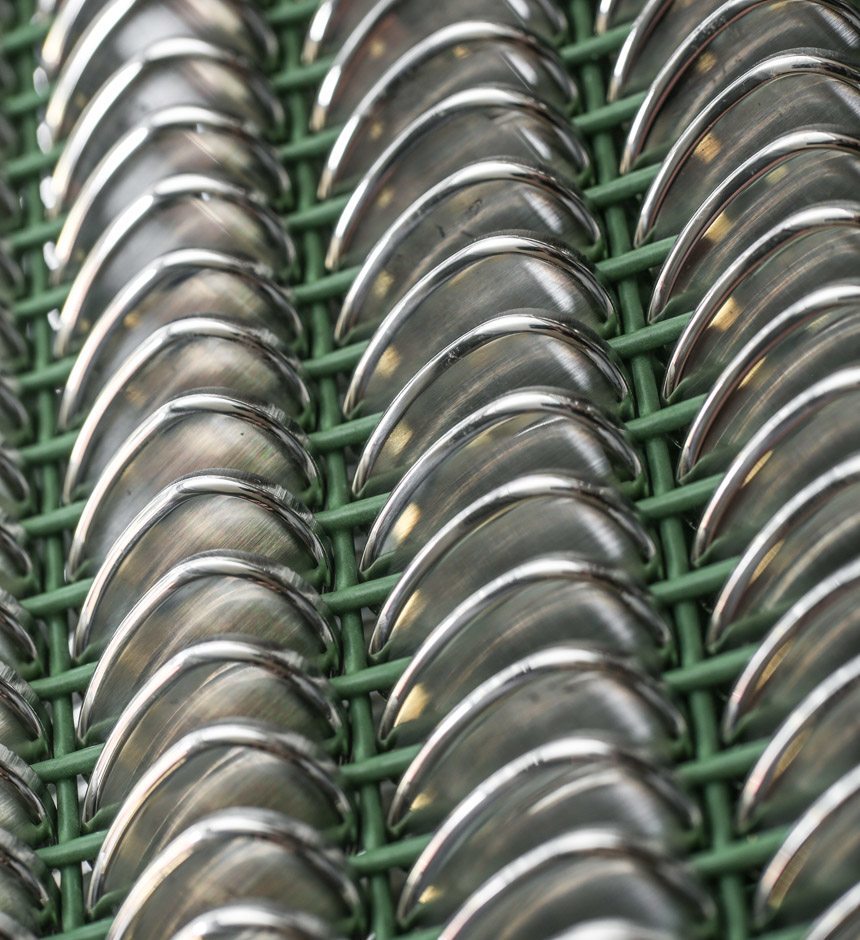

With this, we have arrived to the step where no machine can replace a set of trained eyes and hands: case polishing. Bulgari’s Saignelégier facility has a large room dedicated to this task, with several dozen people working at their benches, deep in the concentration required to get polishing just right. In fact, while a movement, in most cases, can be taken apart and re-assembled again should the watchmaker make a mistake, if a case is badly polished, it very often is non-salvageable.

Polishing works through removing material – it is not simply “smearing it around” on the surface, but rather, with the use of more and less abrasive polishing pastes and brushes, removing an extremely fine top layer of it. If a piece is not polished enough, it will not have a balanced, uniform appearance – which, of course, is totally unacceptable for a luxury timepiece – and if it is exposed for too long or too roughly to the quickly spinning polishing brushes, the material will develop a wavy, uneven surface. If you ever had to suffer a poor restorer’s or watch repairer’s work, you probably have witnessed your beloved timepiece show the former or the latter symptoms.

When it’s done right, though, what you end up with is not only a watch case, but a genuine piece of jewelry. It is no longer an extension, a carrier device of a movement and a dial, but a separate – and yet inseparable – piece of jewelry. Some of Bulgari’s watch designs, like the Octo as seen just above, use extremely complicated geometric designs with alternating finishes – these, with the polished and brushed surfaces so close together, are remarkably challenging to get right; something that only the most experienced case polishers are entrusted with.

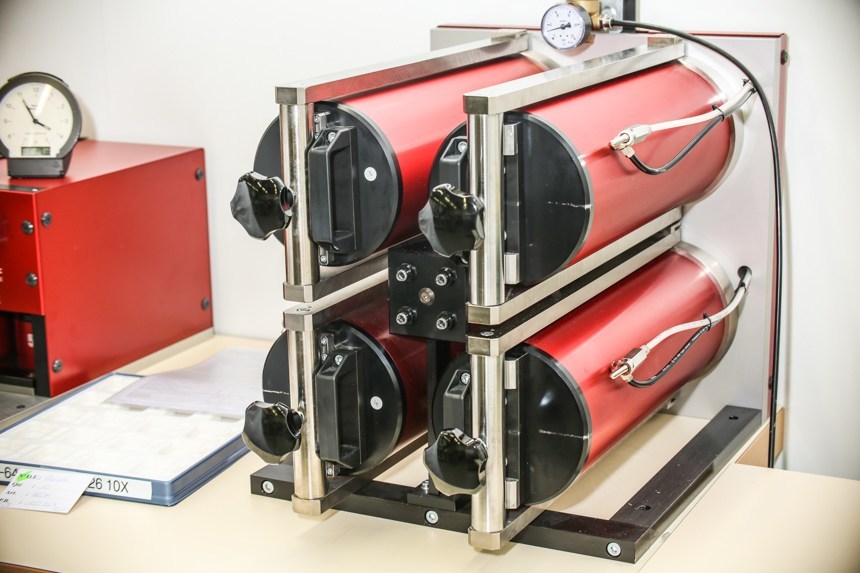

Following a number of final quality checks, cases are assembled – with their crystal and bezel, middle-case, caseback and rear crystal, as well as the gaskets and pushers all fitted together – and are tested for their water resistance. Once this is done, they are sent to a digitized and largely automated storage system, from which they will be dispensed to final assembly, where watchmakers dedicated to the task of fitting the movements, dials, hands and cases together, will put together and, again, quality-check the finished timepieces. This is how watch cases are made, by Bulgari. bulgari.com

Sponsored Content produced by aBlogtoWatch for an advertising partner is a form of article content meant to share information about a particular company through the aBlogtoWatch lens. It is not natural editorial content where aBlogtoWatch includes opinions, suggestions, or reviews. Sponsored Content is written by aBlogtoWatch for an advertiser without an editorial or opinionated angle and is meant to convey facts and media in a way that helps advertising partners share insights and views into their brands and products.