The last major manufacturing site we visited was VMF (Vaucher Manufacture Fleurier), a manufacture whose versatility and complexity could make it the crown jewel of any watch making company. They develop, test and assemble Parmigiani Fleurier watches here, and they also make their movements, ébauches (semi-finished movements) and modules for other brands.

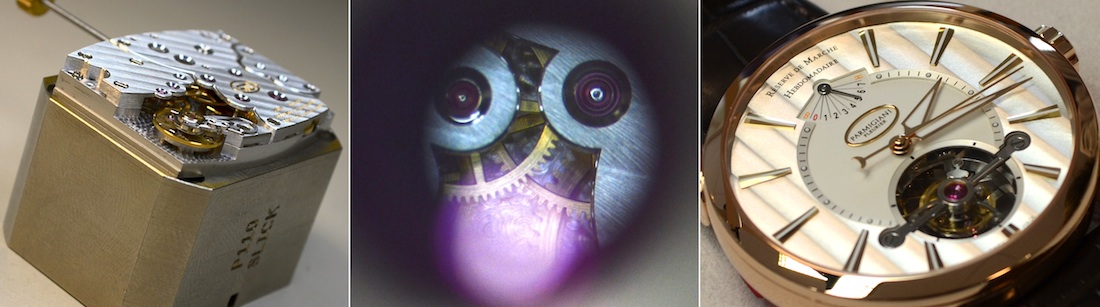

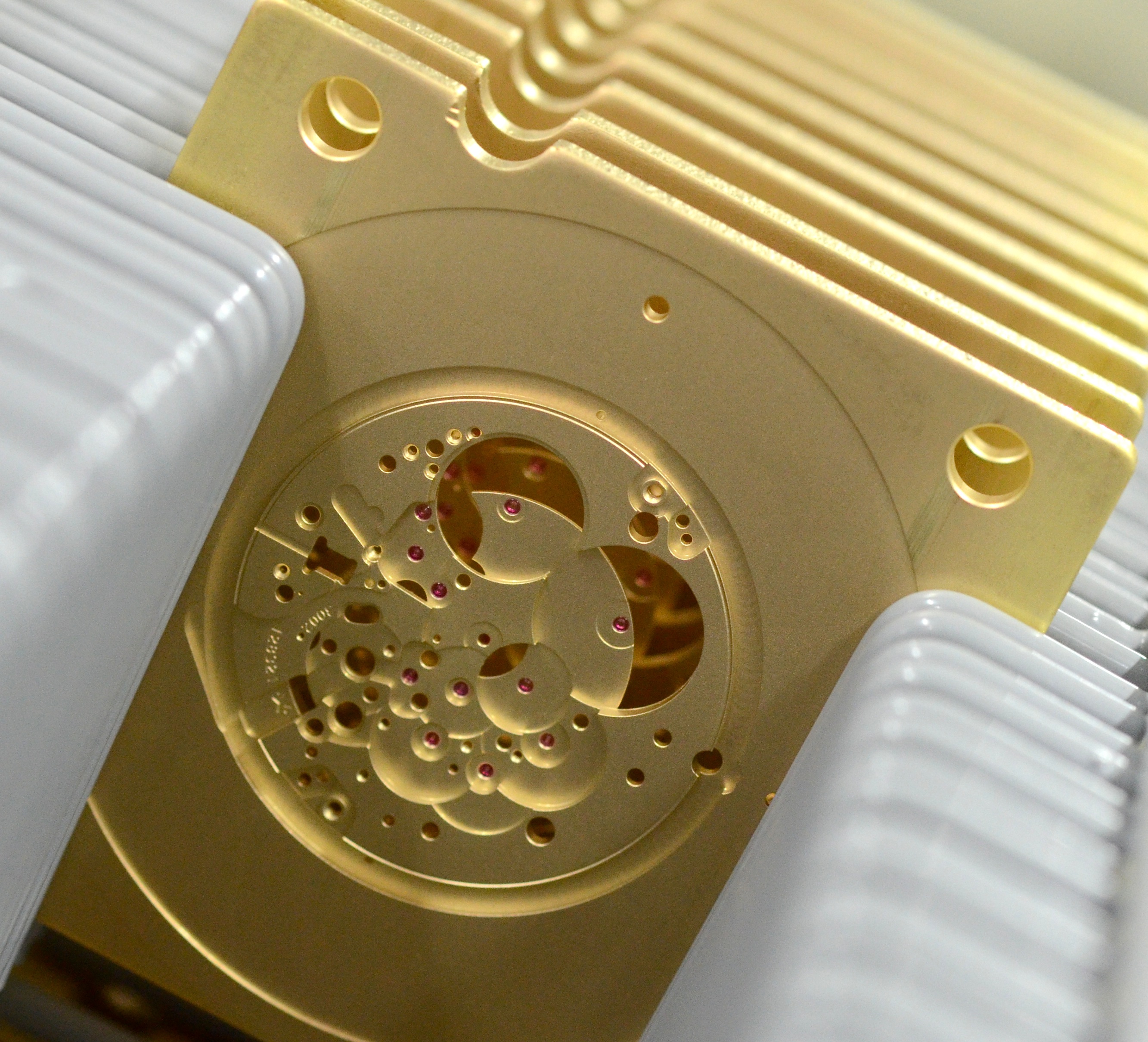

The production of a new movement always begins with several years of research and development. By using computer software and prototyping, they rule out as many manufacturing and reliability issues in advance as is possible. Once actual production begins, they start with creating the main plate for the watch. It is done by CNC machines that adhere to incredibly small tolerances. Despite such accuracy, no part can advance without a person checking them thoroughly to make sure there are no defects or other issues. Plates and other parts are rhodium plated and then – with an almost completely automatized process – jewels are selected and installed into the main plates. This is a reasonable ‘shortcut’ as this process would be very labor-intensive with just about zero added value.

It is also in Vaucher where they do finishing for most movement components. This happens in rooms filled with workbenches, silent craftsmen and the humming sound of different polishing and drilling machines. People are often working on incredibly tiny parts, creating beveled edges and other fine finishes under a microscope. I saw several very recognizable parts for ultra high-end brands being finished here with utmost care. Sadly, taking pictures of these was not allowed by these other brands – and that makes me want to add a short note here.

While visiting this Manufacture I could see key components that would later go into watches priced in or above the $50,000-$100,000 range. The reason why some brands prefer not to disclose who they work with is a complex – and rather weird – issue, worthy of a dedicated article. Nonetheless, despite complicated confidentiality agreements and any marketing ideology one can think of, I still consider this to be a bad decision. To keep my reasoning as short as possible, I will just say that the level of professionalism and dedication VMF harnesses during production is something any brand could – and should – be proud of; even if they do not own the company, just co-operate with them. In essence, I just hope that in the future brands will continue to emphasize their merit in creating their own concepts and designs and not shy away from disclosing which high-end manufacture is making the parts that they dreamed up.

A few stories above the finishing department, larger rooms are packed with fully equipped workplaces where watch makers assemble movements. They do everything except the ‘out-of-this-world’ stuff. In other words, here they make all the movements except those for Parmigiani’s ultra high-end haute horlogerie pieces. They also completely or partially assemble movements or modules for other brands. What is more is that Vaucher has just announced that they now make their own movements too, referred to as VMF Private Label. They currently make two automatic movements and are looking to cater for small high-end brands. There really is no space here to provide more details, but this is something really exciting and we’re looking forward to bringing you more details soon.

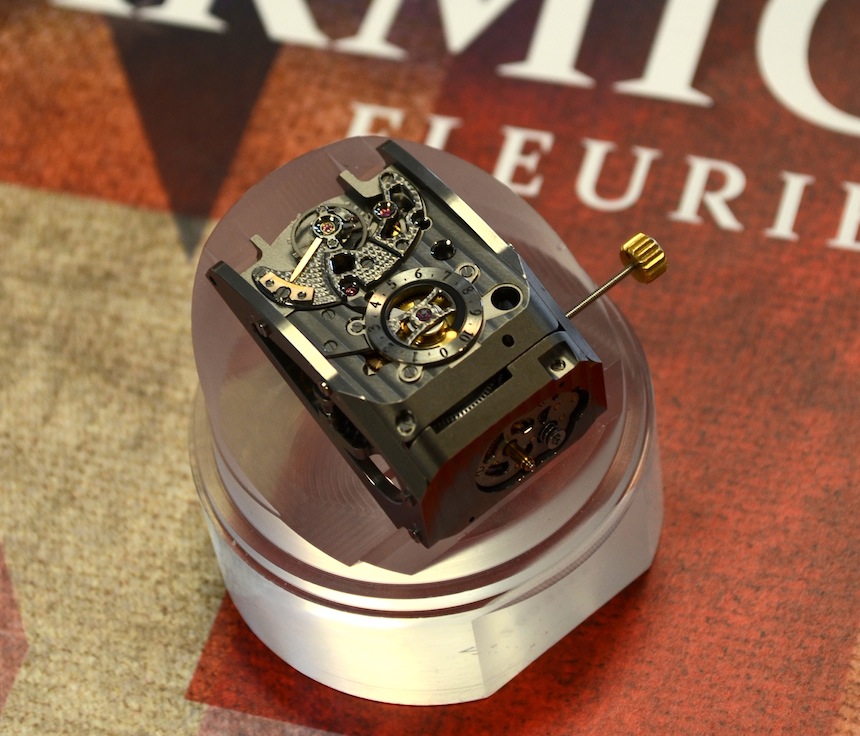

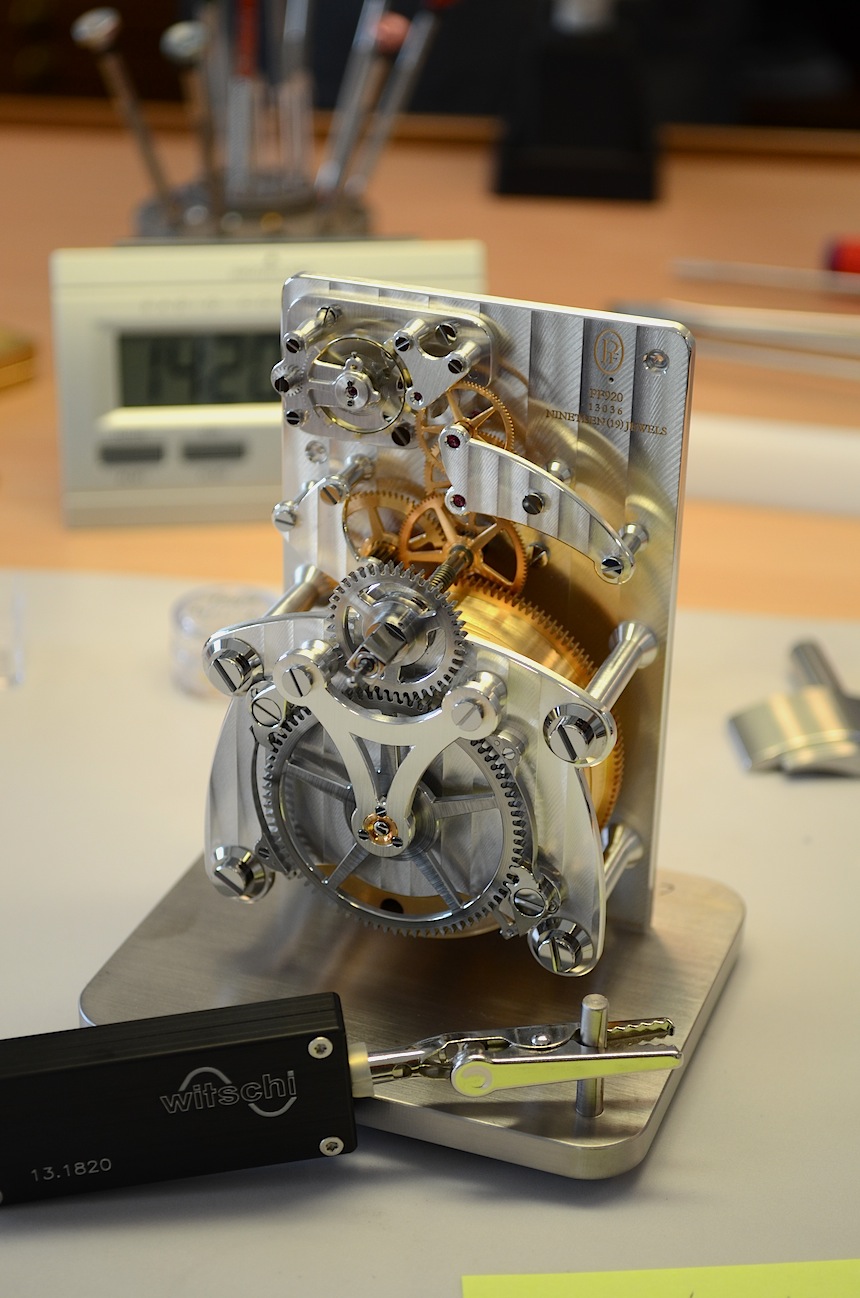

Finally, we arrived to the Atelier Haute Horlogerie. Had I not seen so many amazing things in the other departments, I would say here – inside this beautiful separate building, just across the street from the Parmigiani Fleurier headquarters – is where the magic happens! But that would not be fair, so instead I’ll just say this is where the most wonderful components are united by those best of their trades to ultimately create something that is among the finest of its kind. Sounds over the top, but this is where superlatives meet everyday. It is a world where intimidating CNC machines are changed for small lathes, where constant industrial noise is replaced with silence, and where every movement of a hand strives to be more precise than those guided by computers.

The Bugatti Super Sport with the power reserve dial shown further above, a workbench in the workshop, and a superb minute repeater

It is in this room where centuries of know-how meet with the most modern manufacturing possibilities. Still, making such highly complicated watches can take up to twelve months of a master watch maker’s devoted work – a truly stunning amount of time and effort. The outcome is obvious: very special watches are created here, such as grande complications, minute repeaters, 30 second tourbillons, the limited edition Bugatti watches, and the Ovale Pantograph models, just to name a few.

I just wish I could hang around for a few weeks in here (and I am sure I am not alone with this). I would sit around, watch the different stages of how such fantastic movements are getting closer to completion. I would use the microscope to inspect them for imperfections – a vain venture, I know! And despite the fact that these pieces were right in front of me, it was very difficult to comprehend such levels of perfection and to fully appreciate everything.

In summary, this ‘Watchmaking hub’ truly is an incredible achievement. It provides a unique background that will separate Parmigiani Fleurier from just about any other brand on the market. The only thing they buy from suppliers are the sapphire crystals, the jewels and the hands. That’s it, everything else, even the escapement and all its components are made in-house in accordance with their own specifications. At a time when in-house calibers are the ultimate weapon of choice for high-end brands, it is a great advantage to be able to make them from the ground up all by yourself. It ensures a more flexible production of new models, better overall quality control and complete independence from any other group or brand.

It has to be noted though, that running such an immense group of premium facilities only for the sake of one watch company would not be sustainable at all. Consequently, while annually about 5,000 Parmigiani Fleurier watches are created, the group’s cumulative output accounts for about four times as much. That is because MHF caters to several other high-end brands – smaller and major ones alike -, selling specific parts or complete movements to them. Having said that, Parmigiani Fleurier will always enjoy top priority, and it will reserve more and more of the group’s capacities as it expands.

I sincerely hope that you enjoyed this unique insight into the world of Parmigiani Fleurier. Despite it’s relatively brief history we discovered how they are involved in just about all aspects of watch making, including restoration, watch making training, as well as dial-, case- and complete movement manufacturing.

As a closing remark, please let me point out the extraordinary people working at the brand. Regardless whether they are in manufacturing, marketing or management, I can say with utmost confidence that they are extremely passionate about what they do and are working very hard to keep this brand on the right track and growing at a safe, but steady pace. I would like to thank them for all their kind help and hospitality throughout the week. parmigiani.ch