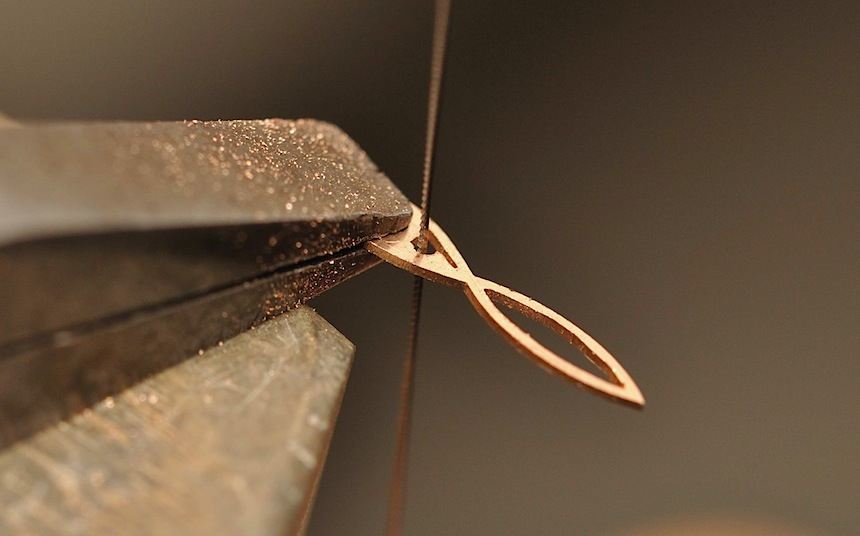

Further above (bottom of page 1) is one of the two workstations for skeletonization, here shows the result of the process.

What you see on the image above is a perfect illustration of how much difference there is between the basic and the finished part, and is indicative of how much work must have gone into creating it. Pieces are engraved and skeletonized by hand and under a microscope – while we have seen other masters use loupes, it came naturally for Michal and Igor to use the microscope. I will say that is more a question of personal preference than a factor that affects the quality of the final product.

Part of the workshop, with two engraving workstations facing one another, a counter with additional machinery, and the watchmaker’s bench in the background

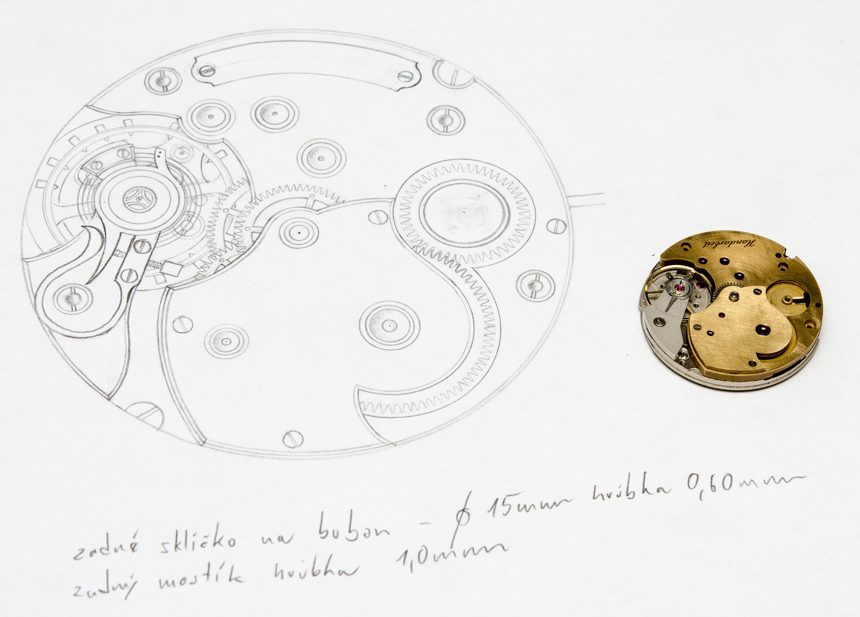

The workshop actually includes two engraving and two jewelry-making workstations, two counters with additional lathes, polishing and sand-blasting machines and one watchmaker’s bench – the latter can be seen on the image above. It includes most required pieces of equipment, including screwdrivers, tweezers and other tools generally used for the assembly of watches. A timing device is used to assure that the chronometric performance of the assembled pieces are in line with what the brand’s discerning buyers expect. This rightfully gives the impression of an established and dexterous two-man team of watchmakers, but that was not always the case: I was surprised to learn how Michal and Igor acquired their watchmaking skills.

The complexity of any and all mechanical movements should be obvious to anyone who has ever seen one exposed through a sapphire case back of a watch and it is with good reason that larger manufactures spend several years on the training of their future watchmakers. As if learning the ins and outs of engraving and skeletonization on their own were not enough, over the years Molnar Fabry went on to learn the basics (and then the more advanced details) of watch movement assembly.

The complexity of any and all mechanical movements should be obvious to anyone who has ever seen one exposed through a sapphire case back of a watch and it is with good reason that larger manufactures spend several years on the training of their future watchmakers. As if learning the ins and outs of engraving and skeletonization on their own were not enough, over the years Molnar Fabry went on to learn the basics (and then the more advanced details) of watch movement assembly.

Disappointed by the subpar work performed by some watchmakers with whom they tried to co-operate when it came to assembling their custom made movement parts, they were motivated to learn how to do all related tasks themselves. Consequently, over the course of several years, they acquired the necessary equipment and through trial and error (and of course by consulting online and printed sources on watchmaking) they have moved related processes in-house.

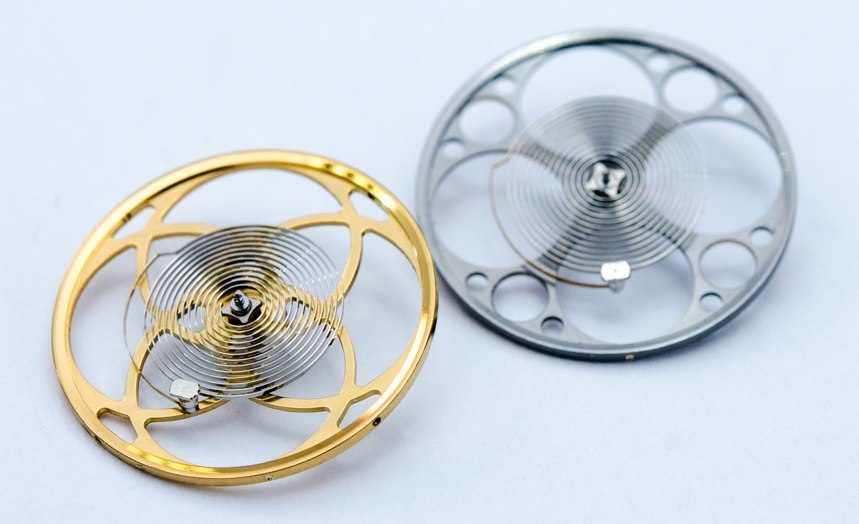

Molnar Fabry’s proprietary balance wheel, designed and manufactured in-house. The microscopic hole in its periphery is used for poising the balance wheel.

The ultimate result – and most notable achievement – of this decision has to be the creation of their proprietary balance wheel, as seen above. Again, motivated by related issues (this time with sourcing this particular component) and also by the need to complete their designs with a more unique balance wheel, the duo have designed and manufactured their proprietary component, to which sourced hairsprings are attached. The latter is more than acceptable as it is completely normal for small (and even for major) brands to have this component supplied by external sources. The investment and the amount of time required to develop the manufacturing background for this tiny spring are truly immense and are completely unattainable by the absolute majority of small and large companies alike.

The wheel offers a more organic design than the two or three-spoke wheels traditionally found in mechanical movements. And while Molnar Fabry commented on improved amplitude and rate results over traditional balance wheels, that really is not the point of this rather beautiful proprietary design. Its primary role is to match all the greatly different custom movement designs that they create and to further separate the final product from the ETA or Unitas movement that it is based on.

The wheel offers a more organic design than the two or three-spoke wheels traditionally found in mechanical movements. And while Molnar Fabry commented on improved amplitude and rate results over traditional balance wheels, that really is not the point of this rather beautiful proprietary design. Its primary role is to match all the greatly different custom movement designs that they create and to further separate the final product from the ETA or Unitas movement that it is based on.

It is one of those countless fine details which ultimately make Michal and Igor’s work stand out and which enable the wearer to get lost in the movement and spend hours on end discovering its many hidden treats. And at a time when so many things in our lives (to a great extent even luxury items) are mass-produced, to find that there still are young craftsmen working under the aegis of their own brand and dedicating their time and efforts to create high-quality (and extremely niche) items is more than reassuring.

Seen here is a finished watch, an early prototype movement, and a pristine vintage movement from IWC.

In essence, the most impressive aspect of Molnar Fabry watches and what they do is to be found in the unexpectedly stellar quality of their work and of course their experience and motivation behind it. These two young craftsmen possess the know-how, the dexterity, and the willingness to dedicate their time and efforts to creating outstanding unique designs and execute them in a clean and truly high-quality way. And while they admittedly are still in a phase of growth, they already are undoubtedly capable of offering a recommendable alternative to those collectors and enthusiasts who wish to have a piece uniquely crafted for them through what is a truly “bespoke experience.”

Given that all Molnar Fabry pieces are one of a kind, prices are quoted individually and depend on the complexity of the design and the materials used. With that said, prices start around $13,000. molnarfabry.com