I have visited several dozens of watch manufactures — a term that is commonly accepted as referring to a watch movement manufacture. And yet, it is the dial and hand manufactures that I find most important and most interesting, followed by the case-makers and movement production facilities. It is distinctly rare for a luxury watchmaker to share in-depth details on the production of dials, and so, combined with my first-hand experience of the Glashütte Original dial manufacture in Pforzheim, I was excited to dig into the 13-pages of informational material that the Saxon brand shared about the making of its SeaQ dive watch dials.

Glashütte Original has a fully integrated movement manufacture in the town of — you guessed it — Glashütte. As Germanly perfect and impressive as that was, with its in-house tool-making, individually heat-blued screws, and so on, its very own dial manufacture in the “Golden City” of Pforzheim was the one that really set my pants on fire. Set firmly in this historic jewelry-making town is a manufacture completely and exclusively dedicated to the production of Zifferblätter, which means that from the thin strips of metals all the way to the beautifully finished, appliqué-laiden dials, they know and they do all when it comes to dial-making.

Before we get to the SeaQ dials, I’ll clarify something. How can dial production be, for me at least, more exciting than movement manufacturing? For a start, very few in-house movement manufactures are at a point in their development where they have the experience and expertise to really get creative and enable their respective brand to go loco on movement designs, new finishing techniques, etc. Yet fewer produce more than just bridges: Wheels and pinions are often out of the question, not to mention specially machined and hand-finished components, blued screws and other stuff horological dreams are made of. Many movement manufactures are extremely limited in their capabilities.

By contrast, a dial manufacture has no other option but to do e.v.e.r.y.t.h.i.n.g. When visiting the Pforzheim manufacture, I was told there can be up to 75 steps to make up the production process of one single dial. That includes stamping, welding, cutting, brushing, polishing, coating, painting, and the implementation of whatever new production method that is required to create a new moon phase disc, or to faithfully recreate a modernized version of a dial from the 1960s. All this, each and every step, is expected to be performed with mind-bending minute tolerances, with virtually zero tolerance for blemishes.

A mistake at any of those up-to-75 stages renders the production piece useless, necessitating the discarding of the piece, binning all the working hours that have gone into it up to that stage. Not surprisingly, a handmade watch dial is a remarkably refined and equally expensive component in any luxury watch. Facts, like how you’ll be looking at it more than any other part of your watch (except for the hands), and the consequent importance attached to it, are all self-explanatory, really.

Since they took their trademark form in the early 1950s — with a rotating timing bezel, luminescent time display and running seconds indication — true divers’ watches have not only complied with their ISO 6425 requirements but have also tried their best to create their own unique aesthetics. Such was the case with the Spezimatic Type RP TS 200, a diver’s watch developed specifically for sports and combat divers in 1969 by the company. This watch, pictured below, serves as the inspiration for the recently introduced SeaQ line of timepieces.

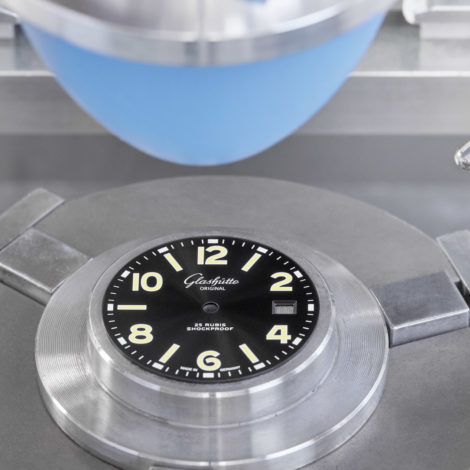

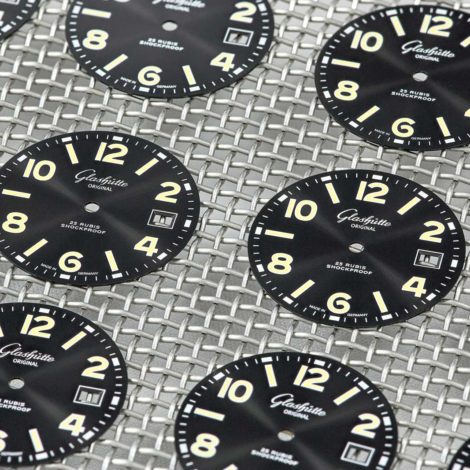

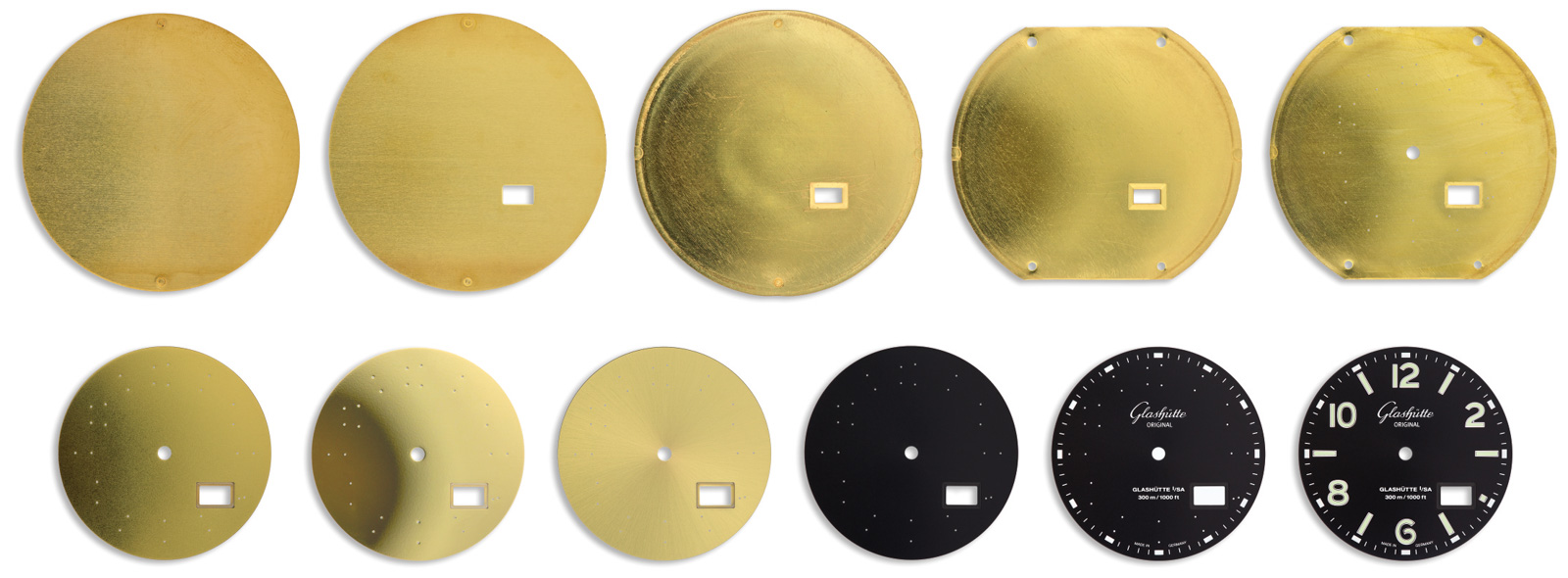

Because a faithful recreation with the 39.50mm SeaQ, and a modernized version with the 43.20mm SeaQ Panorama Date, was Glashütte Original’s goal, the dial manufacture had to create two very different dials, in two color variations (blue and black) of each. One with printed numerals and a decidedly old-school vibe over a 30.50mm-diameter dial, and another with hand applied indices and a more contemporary look over a 33.1mm dial that incorporates the larger aperture for the brand’s large Panorama Date indication.

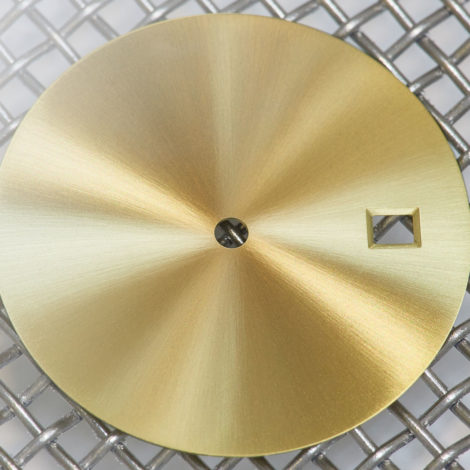

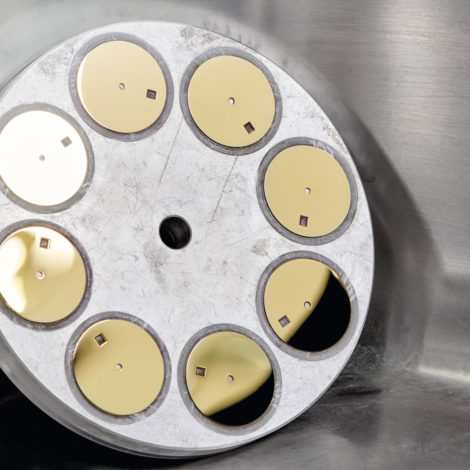

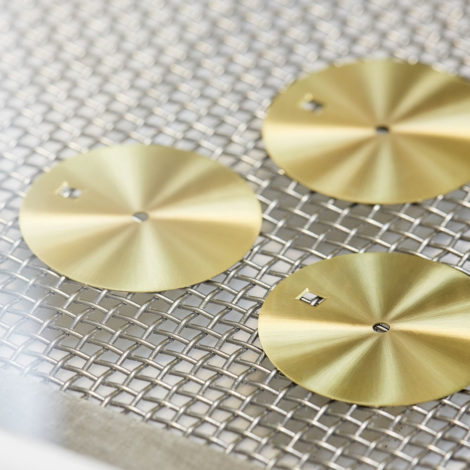

Every dial starts out as a blank, punched from a strip of brass. The process adds a total of four catch holes which will allow the blank to sit securely and precisely where it should as it undergoes subsequent processes. A bit later the date window gets its cutout, yet later enhanced by adding a decorative, beveled edge. Then it’s time for the central hole for the hand pinions to come through, along with some infinitesimal holes that will accommodate the tiny feet of the indices on the SeaQ Panorama Date — two per index. At last, the dial gets punched from the blank, giving it its final diameter, just as you see it above.

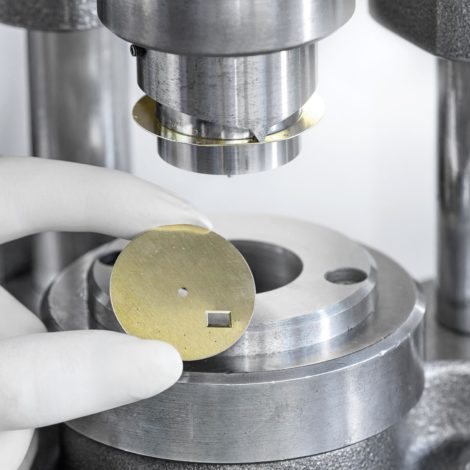

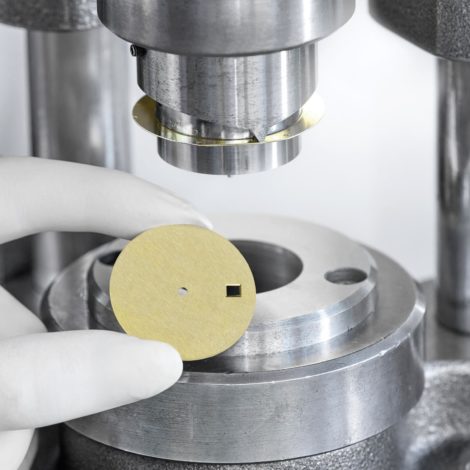

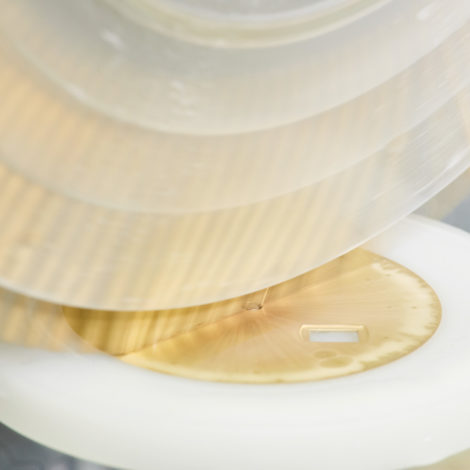

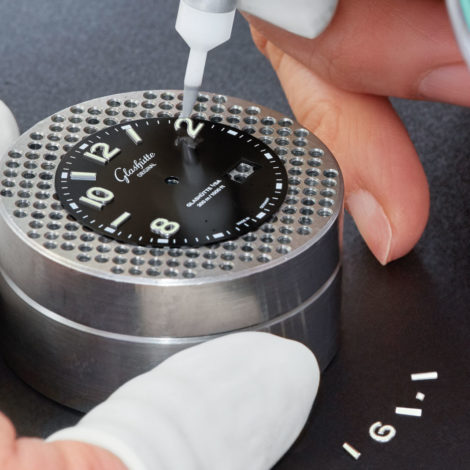

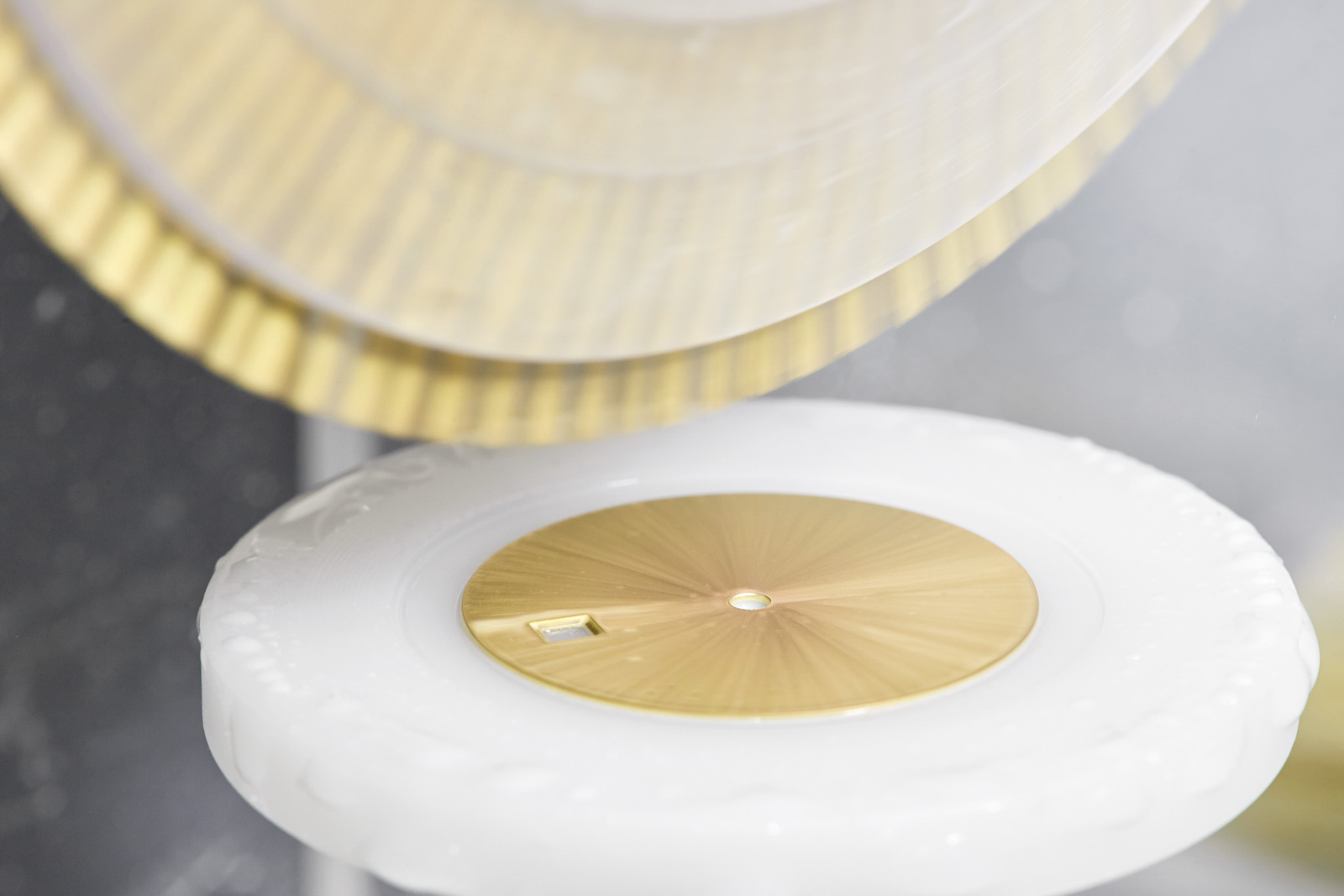

Time comes for surface treatments, a whole new dimension in know-how and extreme care. A grinding and polishing machine and a special emulsion liquid are used to grind the dials before polishing them to a high gloss finish. Now that a nice, perfectly even surface is achieved, the subtle sunray finish that will glisten through the color of the dial is applied. The dial turns on a rotating platform and is finished by a brush rotating on a vertical axis. I’m still baffled by just how even a surface can be created using such a seemingly basic method.

I especially like this stage of wet, painted dials. A wet dial is not something you’d ever want to see on your watch — dive watch or otherwise — so, to see this delicate object go through a phase like this I found quite unnerving and entertaining at the same time. The base color of a SeaQ dial is attained through galvanization, a process that can create stunning colors… or their very opposite. Blue is especially tricky to get consistently right, as literally seconds over or under the desired time in the galvanic bath will result in a different hue of blue.

Rinsed clean and dried, the dials are all set for the application of numerals, indices, logo, lettering, and other details. For the throwback version of the SeaQ (with the date at 3 o’clock), first the numerals and indices are applied in a light primer color. Contrary to what some may believe, not all prints are applied at the same time. Then, the printing pad (also called a tampon) picks up the ink from an etched plate (also known as a cliché) that holds just the right amount of paint in just the right places. The pad is pressed against the dial to transfer the paint. Needless to say, the amount and location of the pressure of the pad, and the paint it carries, are the key elements. The same happens with the white texts and details. Then, the numerals and indices are filled in by hand with Super-LumiNova — having never been able to stay within the lines on much larger scales, my trying this process has led to hilarious consequences.

Like tiny cufflinks or earrings, the applied numerals of the SeaQ Panorama Date truly look like tiny pieces of jewelry. While the logo, other texts and the minute ring are pad-printed on this model, all other indices and large Arabic numerals are applied by hand, all fourteen of them. The appliqués feature green Super-LumiNova paint on the black dial versions and white Super-LumiNova paint when used over the blue dials. The indices, as mentioned above, are secured not by glue but by two tiny feet that are then welded to the back of the dial, with all excess material removed to maintain its flush surface, so that it rests flat against the movement underneath.

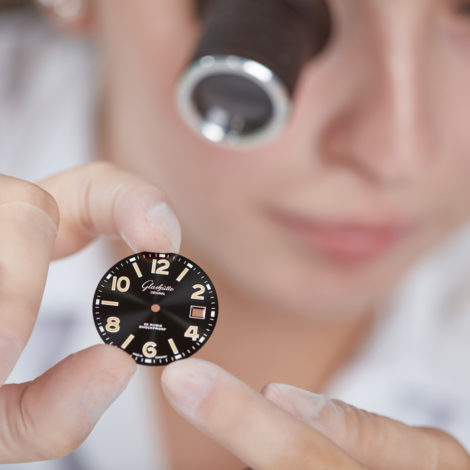

As one would expect, quality-control procedures are in place throughout the processes, including at the very end of the dial production. Once a dial is cleaned and checked thoroughly, it gets packed away safely and is transferred from Pforzheim to Glashütte Original’s main manufactory building for final assembly.

To go from a meters long, thin, uninspiring strip of brass to something that serves as the backbone of the identity of a watch — that’s what makes dial production so special. Add to that the fact that every step along the way is carried out in-house, within the same building, by the same one group of technicians and craftspeople, and you start to appreciate how movement making should not be the be-all and end-all of “in-house” production when it comes to luxury watchmaking. Learn more at glashuette-original.com.