The new Ameriquartz isn’t too distant a relative of many “Swiss-made” Ronda movements which are also comprised of imported and domestic parts and then assembled locally. Let’s also not forget that to bear the “Swiss-made” distinction, a watch or its movement only needs to have 60% (up from 50% in 2017) of its total value — including assembly and final inspection — be realized in Switzerland. This of course, pales in comparison to “American-made,” which notoriously requires that any goods bearing this title be manufactured completely in the United States. And given the staggering difficulty of this task in the highly globalized watch industry (translation: it’s all but impossible at the moment), any American company even lightly overstating their manufacturing capability can certainly be expected to get a call from the FTC, as Shinola infamously did back in 2016.

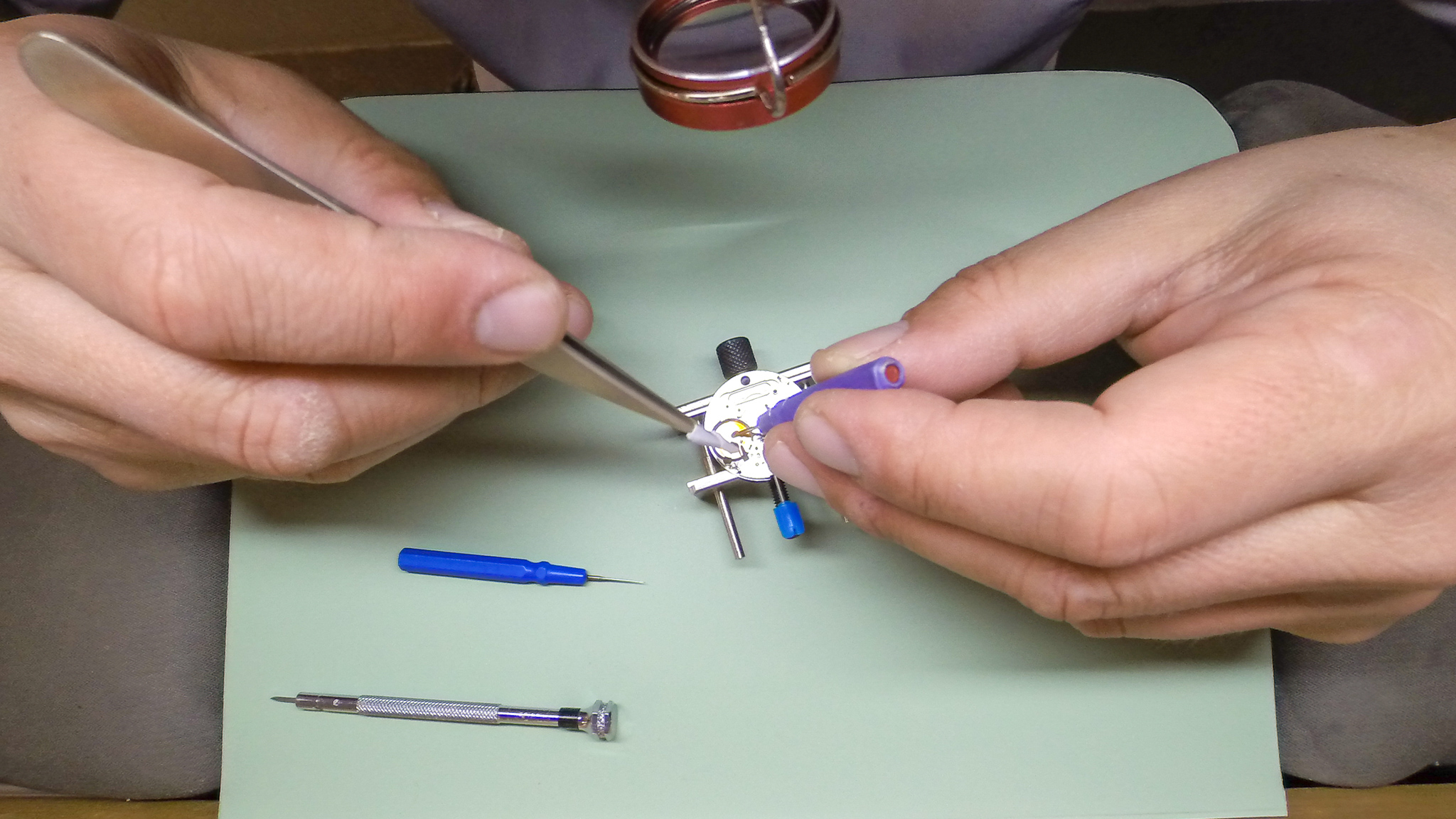

As for the Ameriquartz movements themselves, if you’re an established microbrand or upstart U.S.-based watchmaker whose customers demand American-built products, there’s certainly a lot to get excited about. Comparable to a high-end ETA quartz movement, the Ameriquartz movements are built with metal baseplates and employ jeweled bearings, making them easily serviceable or repairable by any competent watchmaker. The base-level complications shouldn’t come as a surprise to anyone familiar with Ronda or ETA-based quartz movements, which include two- and 3-hand, as well as day/date movements that start at around $15 (not far from a comparable “Swiss-made” Ronda movement) for relatively modest minimum order quantities. The catalog also contains more exciting stuff, like pointer dates, a big date, world time, moonphase, and various chronograph functions, all with new and interesting layouts that offer some potentially exciting variation on the current limitations of Swiss-, Japanese-, or Chinese-made movements. And this design freedom is really where the future for Ameriquartz lies — especially with brands that can operate on a scale large enough to leverage Titan’s impressive manufacturing capabilities to create something truly unique and innovative for the watch community.

American startup Vaer Watches assembles its field watches in Los Angeles, using movements of Swiss and Japanese origin

FTC wrist-slap notwithstanding, Shinola has proven many times over that there is absolutely demand for products of U.S. origin (perceived or otherwise), but the real question here is whether or not there’s a demand for American-built movements. Ryan Torres, founder of Vaer Watches in Los Angeles was cautiously optimistic: “While the Ameriquartz movement performance is yet to be seen, we were incredibly impressed with their [FTS] assembly facilities, and how they’re the first real scalable solution that we’ve seen in the U.S.” That scaleable solution begins with the current knowledge base and facilities for movement assembly but is expected to expand to include case and dial manufacturing capability in the near future, hinting at the possibility that a more comprehensively American-made watch could be closer than some might think.

Between brands, retailers, distributors, and other supporters present for the tour, the general tone around our day at the FTS facility was consistently one of hopefulness underscored by Torres’ cautious optimism. Working Ameriquartz movements are already being produced and assembled at the FTS facility, and fitted to watches that are already on wrists, so it’s no longer a question of whether something on this scale was even possible, but whether or not an American-built movement is an important enough concept to entice consumers.

Mullin certainly seemed to think so, adding that “Abingdon customers are pilots, scuba divers, and NASCAR drivers — women who tend to be pretty hard on their watches — so if FTS can produce a watch that can keep up with them, I’m confident they’d rather buy and own a watch that’s as American-made as possible.”

Don’t forget it took the Swiss watch industry many decades and incredible depth of resources to establish the now deeply entrenched cachet of “‘Swiss-made” as a universal badge of quality (a status that was quietly wrested from the American watch industry around the middle of the 20th century), and I’d expect it to require even more effort for “American-made” to even begin to challenge this status quo. Assuming the quality of the Ameriquartz movements is on par with what ETA or Ronda can produce (all signs suggest they are), there’s then the bigger quandary of consumer education and demand. As we all know, there’s no shortage of predictable, affordable, and readily available movement alternatives from trusted Swiss, Japanese, and Chinese manufacturers, so the decision for small, bootstrapped American brands like Vaer and Abingdon to choose Ameriquartz over an established industry giant could partially amount to being one of altruism or physical corporate proximity — and is that really a bad thing?

Ultimately, I’d argue that increased manufacturing diversity and competition in any industry ends up best serving the consumer. And when it comes to watches, anything that could someday force industry heavyweights to take notice, adapt, or innovate will ultimately yield the best quality, the most interesting, or the most affordable products for the consumer to choose between. With the next generation of American watchmakers now in the driver’s seat, it goes without saying that I can’t help but root for what Ameriquartz represents and am eager to continue following this new (ahem) movement percolating in the Arizona desert. For more information on the Ameriquartz movements, visit Fine Timepiece Solutions’ website right here.