In fact, the Moser Watch Holding is split into two sister companies, with the H. Moser & Cie. watch manufacture comprising some 43 watchmakers, engineers, and staff, and Precision Engineering AG another 12, making for an enterprise that today employs 55. The company’s on-site R&D department, technical section, and movement component manufacturing, as well as the integrated assembly workshop not only ensure most parts of an H. Moser watch movement are made in-house, but that all design, research, and development take place here, giving H. Moser & Cie. total control over quality.

Precision Engineering AG is highly specialized in producing hairsprings of all sorts, as well as balance wheels, rendering it one of only a handful of ultra-high-precision companies with the necessary machines and know-how required to produce what are, without question, the most complicated and essential components in any high-end mechanical timepiece today.

The watch manufacture H. Moser & Cie. is responsible for carrying on the Moser name through watches it designs, develops, and refines in-house, and through producing the key and unique components of its unusual calibers also right here, in Neuhausen am Rheinfall. It goes without saying, that Precision Engineering AG supplies Moser watches with their special balance wheels and hairsprings.

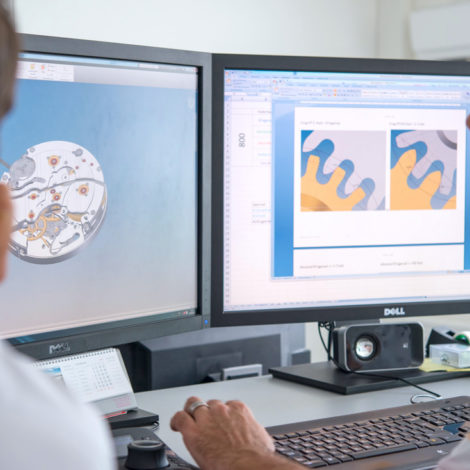

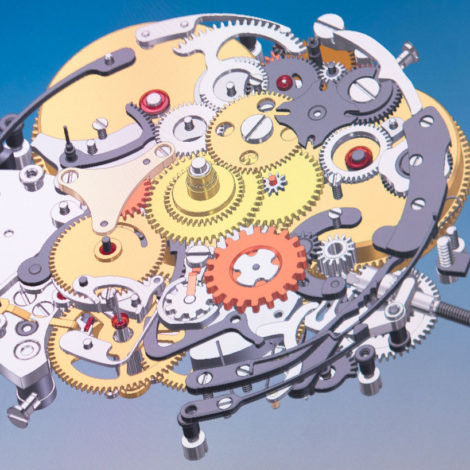

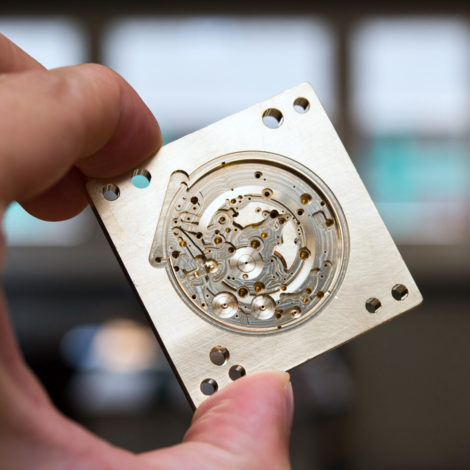

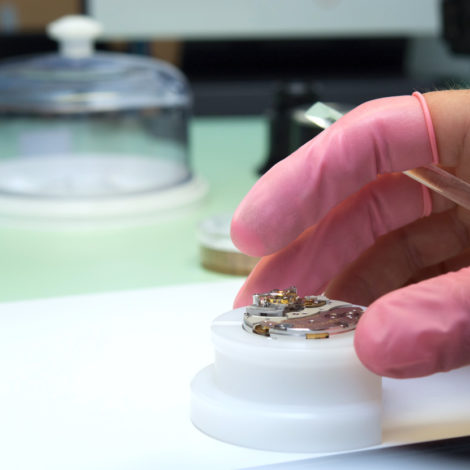

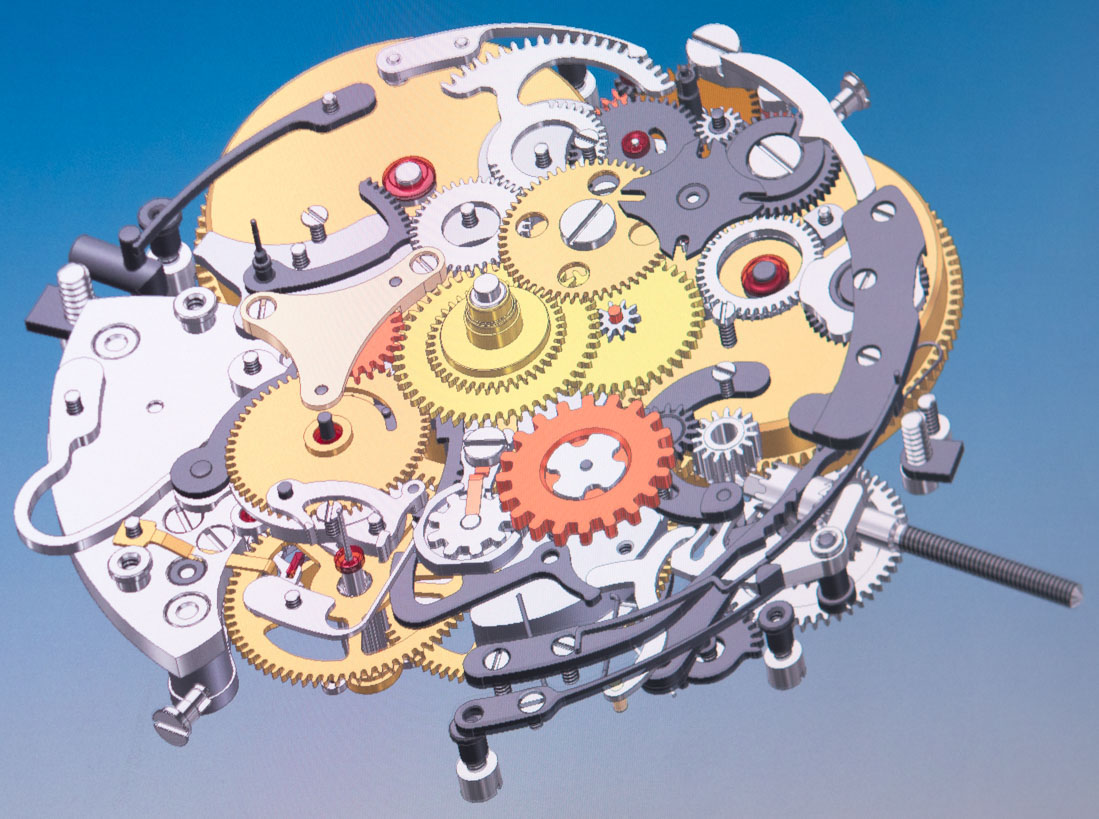

Further above: CEO Edouard Meylan and Arnaud in the R&D development. Directly above: an H. Moser & Cie. perpetual calendar caliber with its bridges removed shows a remarkably clever arrangement of in-house designed parts.

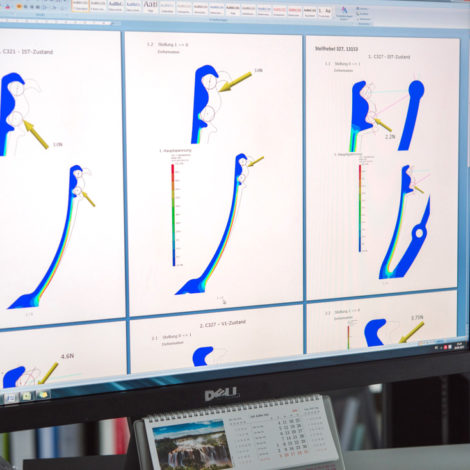

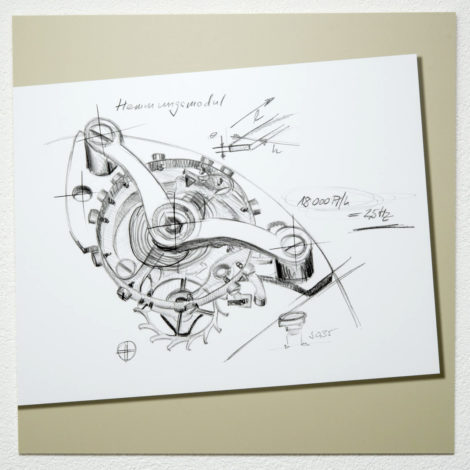

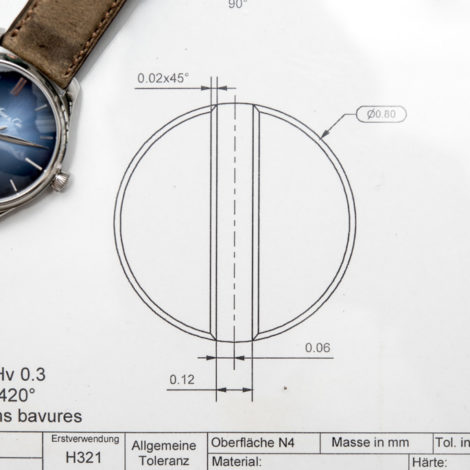

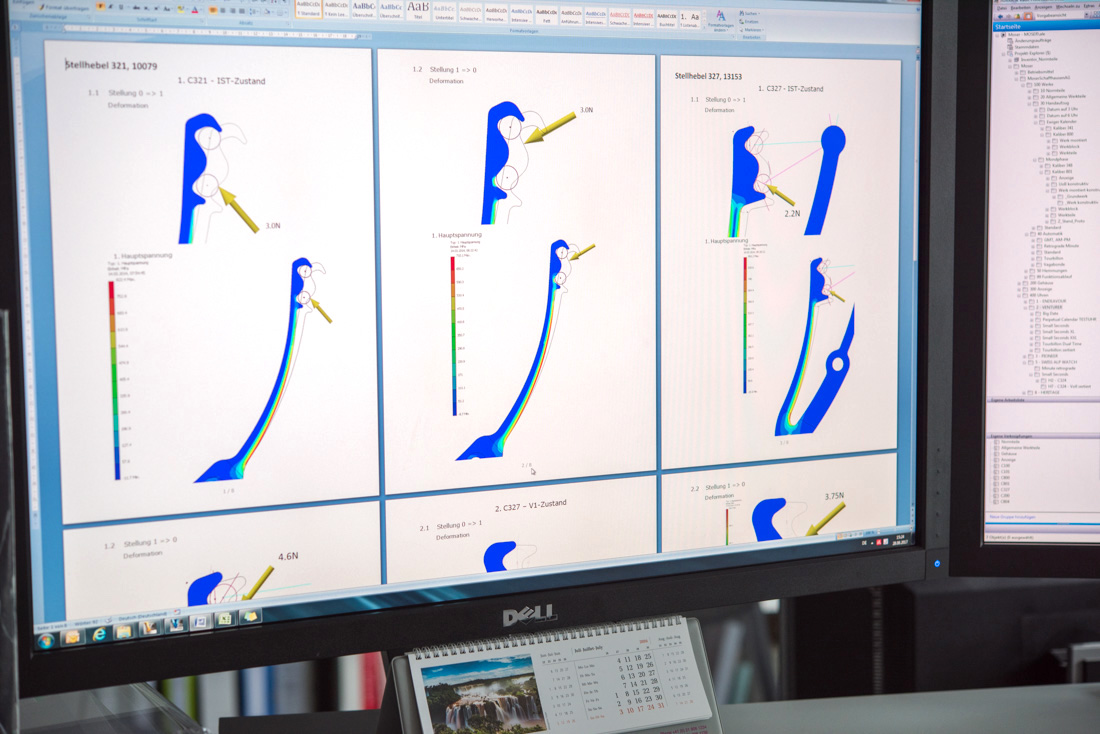

At Moser, things begin with design, research, and development, which includes computer aided design, sketching, as well as prototyping at different scales, all to determine and fine-tune the functionality of each new idea. This is what has led to the modern Moser using a modular escapement in most all its movements, the safety of a double pull crown, or the easy-to-use and yet easier to read, though also rather complex Perpetual Calendar, the trademark look and complication of H. Moser & Cie.

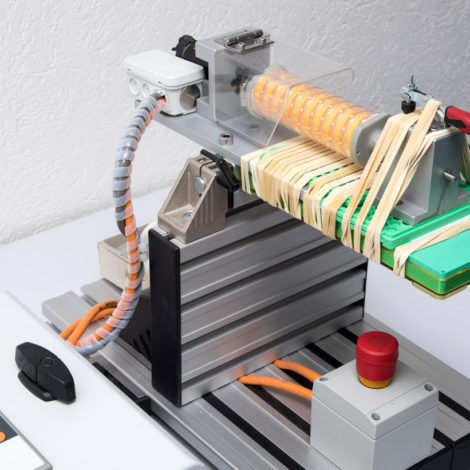

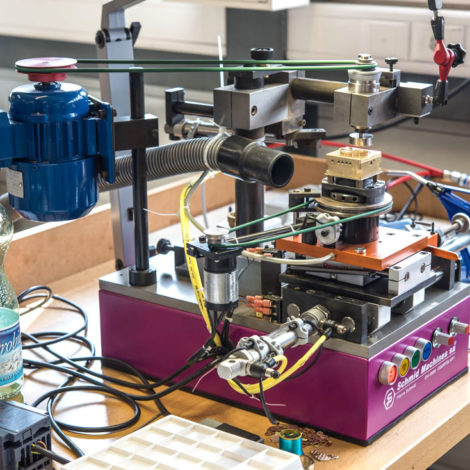

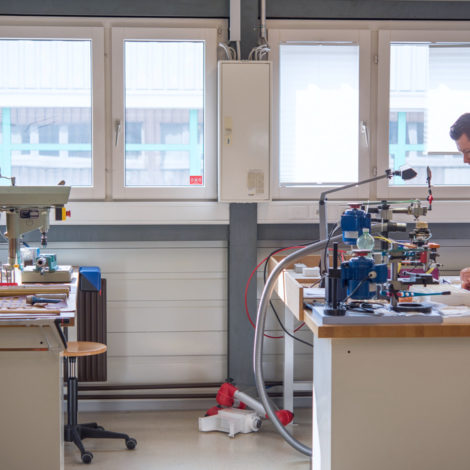

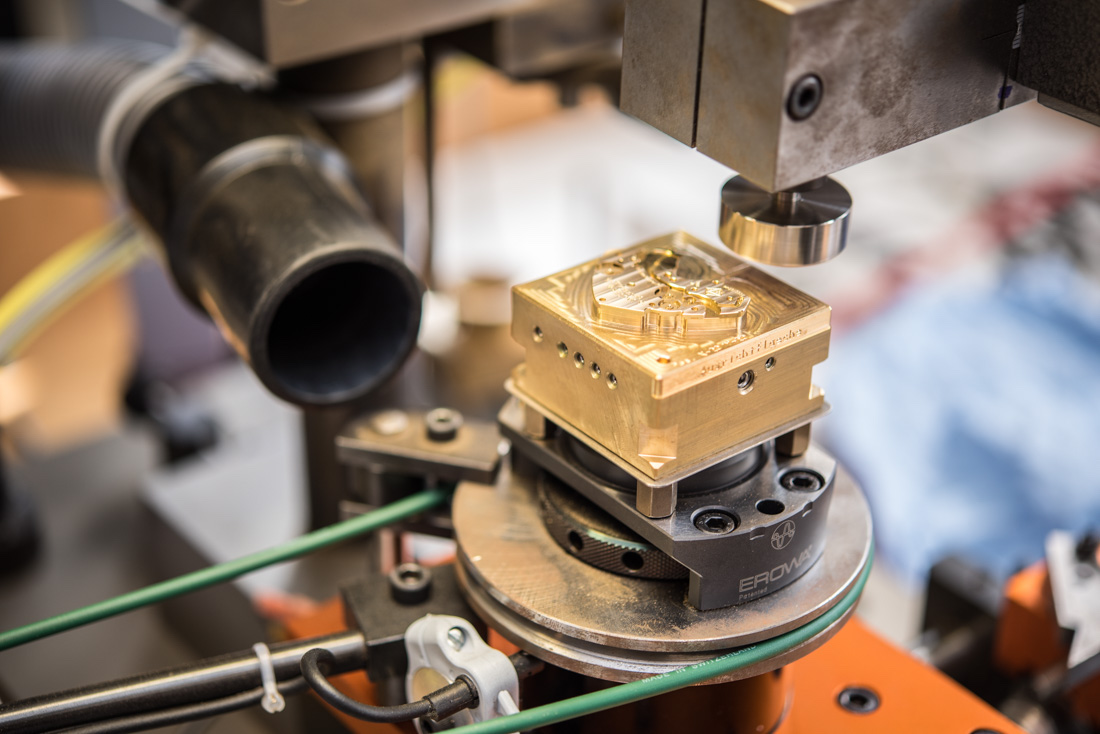

Parts, such as specially designed spring, plates, wheels, and cams are tested here – projects that at times necessitate the fabrication of 3D-printed prototypes and creatively engineered tools, like that machine directly above that tests ten calibers at once to determine the efficiency of the newly developed automatic pawl-winding system that powers the HMC 230 caliber, beating inside the new Pioneer Centre Seconds Automatic.

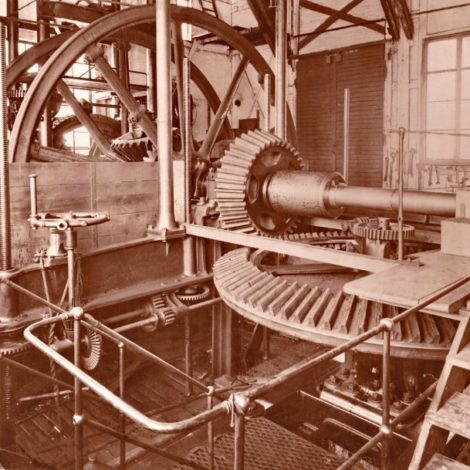

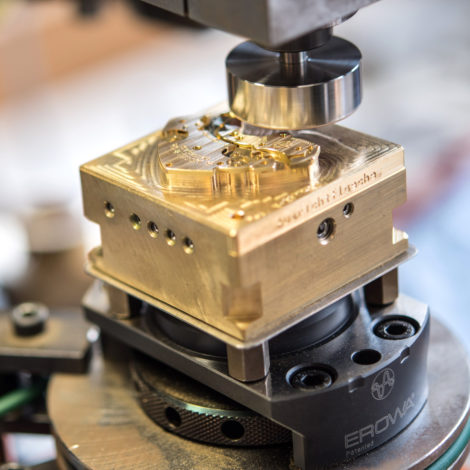

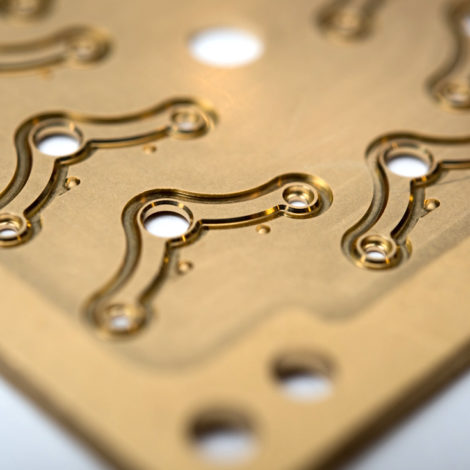

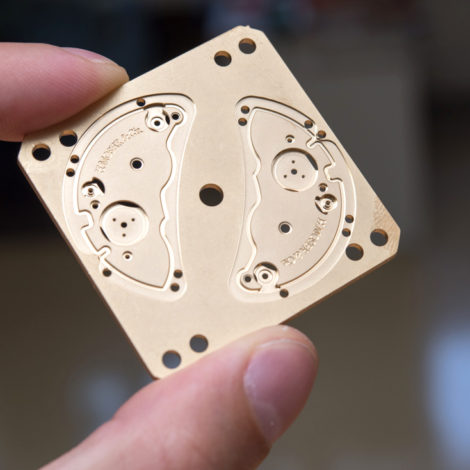

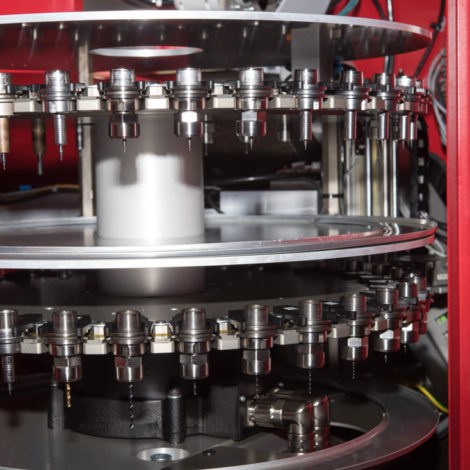

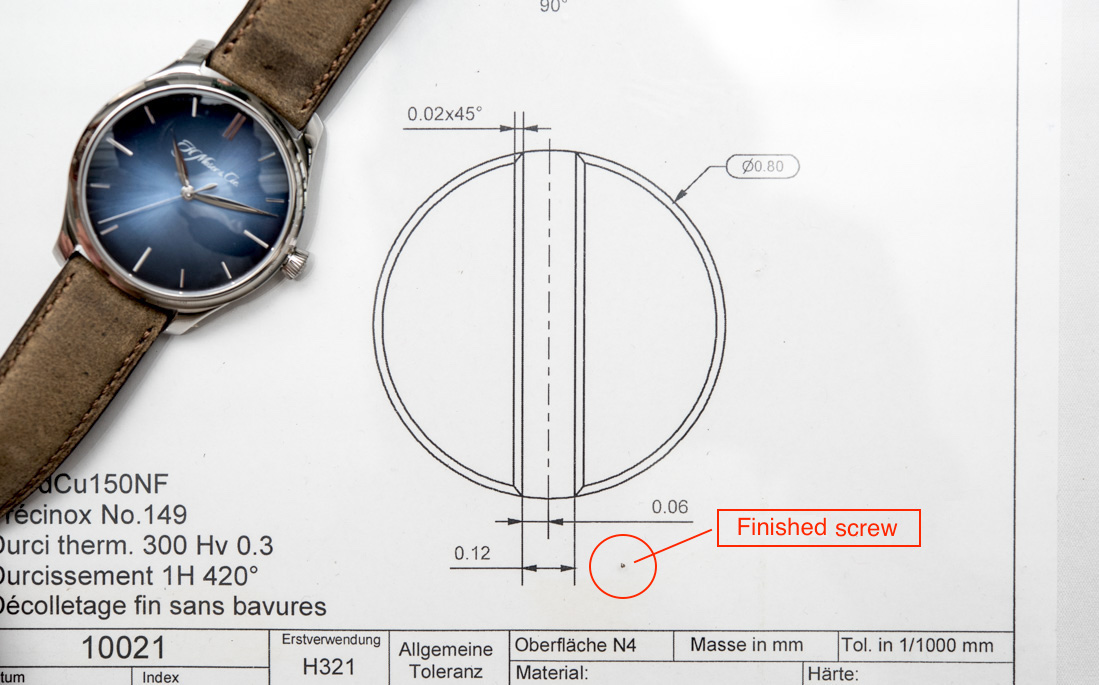

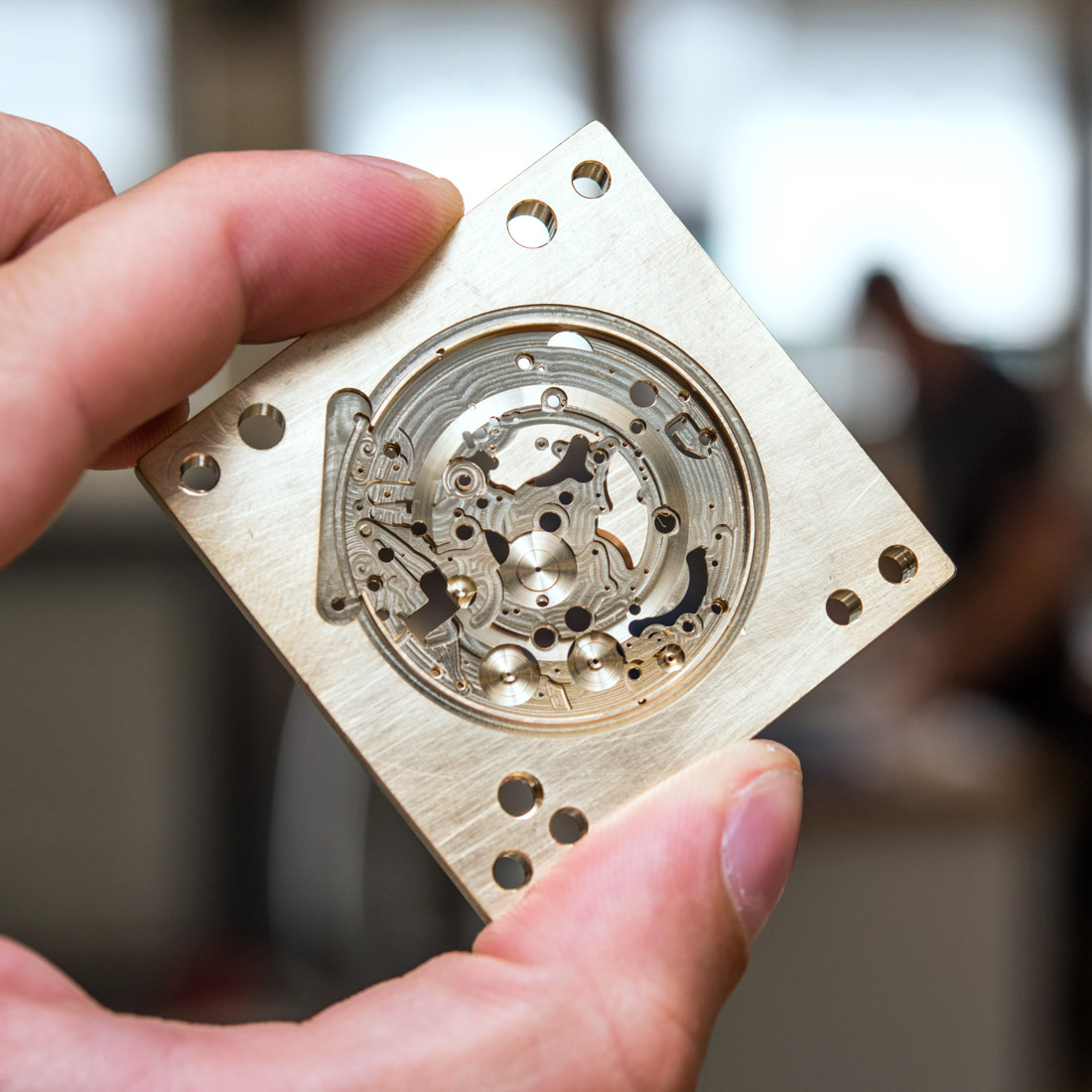

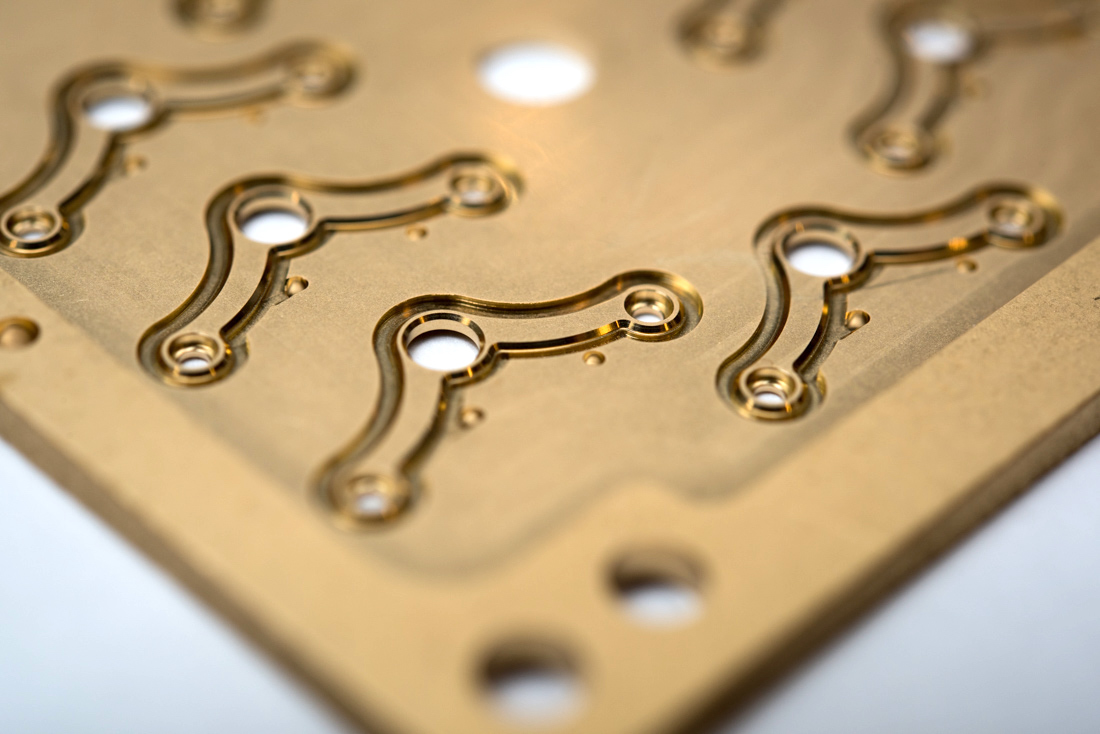

Production of the in-house designed components takes place a floor below, on the ground level, where massive and highly capable machines are at work, juggling up to 87 different tools, picking the correct one to perform the required machining operations; though their full capacity is 95 tools, which means there is a bit of room for yet greater complexity, should that be absolutely necessary. All parts go through meticulous quality control in between the different processes, before they could be decorated and put on the desks of the watchmakers.

A machine, once again specially built for the purpose, performs the Moser double stripes on the top parts of the plates: a series of stripes are added to the top segments of the top plates in an alternating fashion, creating a more unusual and fascinating caseback look on all H. Moser & Cie. watches. The edges are bevelled by diamond-tipped tools that can perform extremely precise and truly beautiful finishing, only to be perfected through the touch of a master craftsman with a set of trained eyes and hands, before the piece is sent on to be used in a caliber.

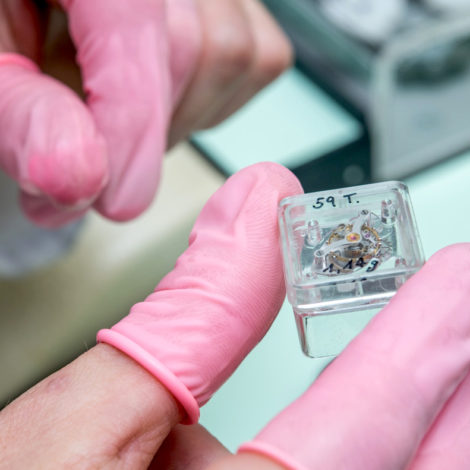

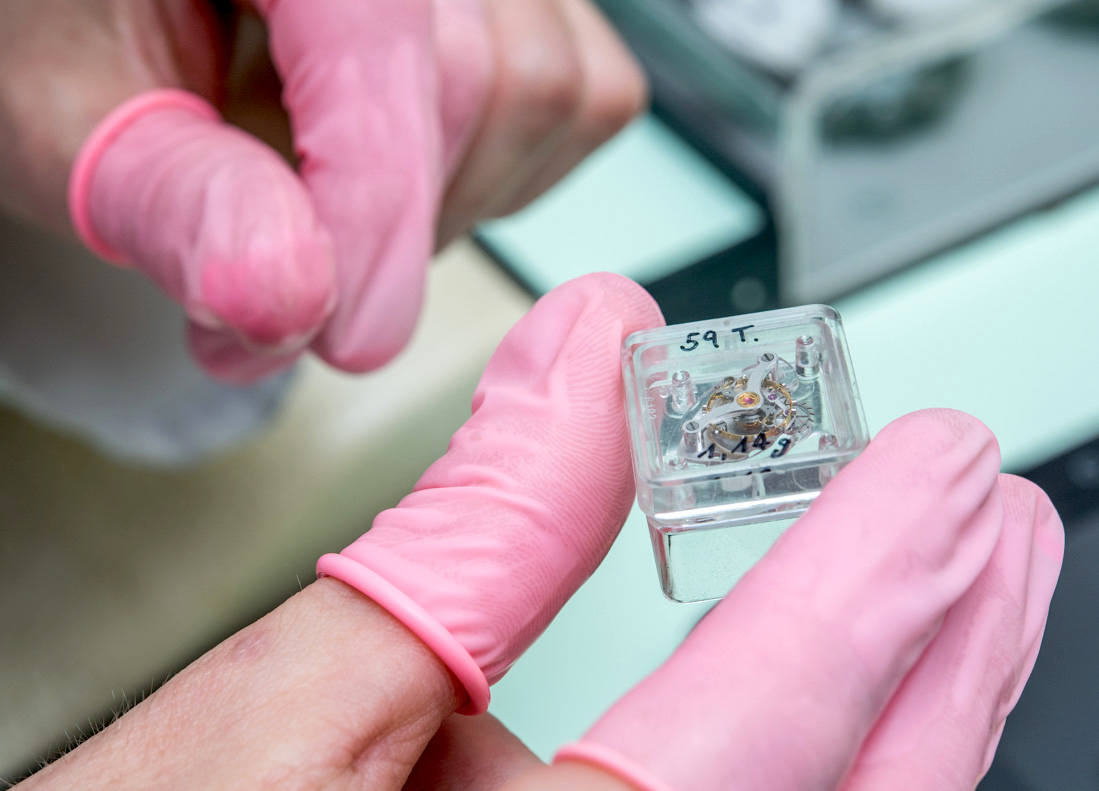

The truly inspired and unique idea of modular escapements – where the entire escapement is constructed and tested before being fitted to an otherwise complete movement (after which it is tested for another 10 days) – we will look at in greater detail in another, dedicated article. For now, we will say that most H. Moser & Cie. movements feature this escapement, and that once the individual pieces have been designed, prototype-tested, crafted from a plate of metal, and finally decorated, they can at last set off to play their very own role in an H. Moser & Cie. watch.

An unusual quirk of the H. Moser & Cie. manufacture – or, rather, a fun fact about its watchmakers – is the lack of air conditioning in the assembly rooms, at the specific request of the watchmakers, who prefer to work in the clean, natural air provided by the outskirts of Schaffhausen. In the summer, when temperatures are high in the afternoon hours, they say they prefer to start their days that much earlier.

As is expected, once the movements are completed, all timepieces are cased up and tested in-house by H. Moser & Cie., to ensure they comply with the manufacture’s requirements for accuracy, water resistance, and aesthetic qualities.

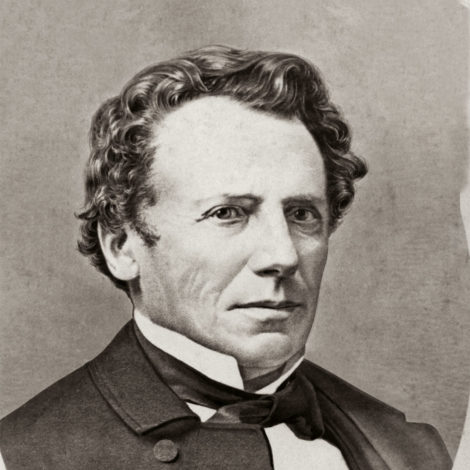

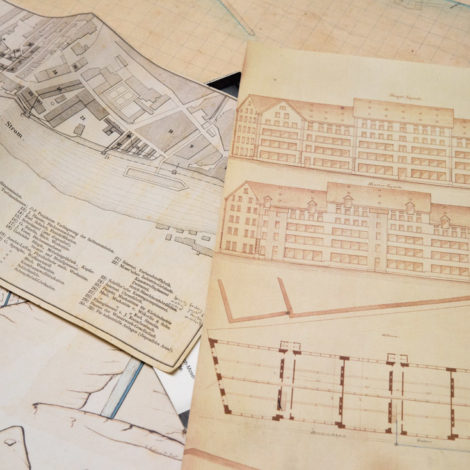

It is true, the Meylan family took on a great challenge and responsibility, when they set off to take on the H. Moser & Cie. name, a name synonymous with entrepreneurialism for those who are familiar with the story behind it. From young watchmaker to industrial revolutionist, Heinrich Moser went on an incredible journey some 150 years ago, and though times have changed in the world, H. Moser & Cie. to date nurtures and perpetuates its founder’s striving for independence and new adventures.

As such, since under the caring direction of the Meylan family, H. Moser & Cie. went on to be a truly disruptive element in the Swiss watch industry, noticed by collectors and enthusiasts alike for openly calling out issues linked to how Swiss Made luxury watches truly are, and for tackling more tactile and traditional challenges, like producing the most legible and deceivingly simple perpetual calendar. All this goes to prove the attention the name and manufacture of H. Moser & Cie. has enjoyed lately – and also how a watch brand can get on the global map through a bold entrepreneurial spirit, while being Very Rare. h-moser.com