Contributed by İlker Özcan, who is a professional Materials Engineer and owns a small R&D company (www.ndsgn.com).

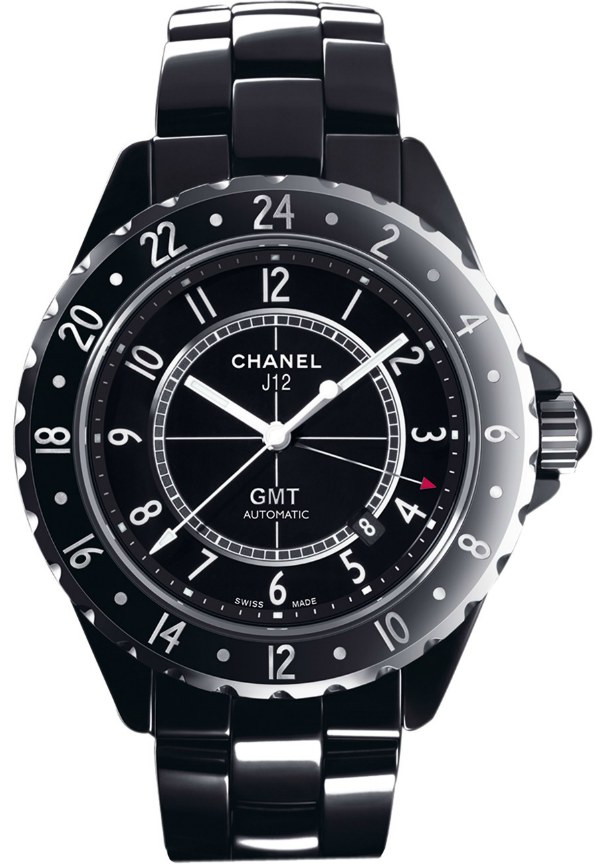

In this article on watch case materials, we have decided to write about ceramics. Ceramics are possibly the least understood of the materials used in watches. Many watchmakers are nowadays using ceramics for their watch cases – which gained popularity with Rado. Now Chanel, Hublot, Omega, IWC, and many others produce watches with ceramic cases in full or in part.

Materials are generally classified as Metals, Polymers, Ceramics, and Composites. Sometimes foams, etc… are added but these four classes are universally accepted. So ceramics are one of the three main classes, where composites are mixtures of these three.

Ceramics are essentially inorganic solids (organic ones are polymers) that are also not metals. So in addition to what is usually thought as “ceramics”, glass, diamond and graphite are classified as ceramics. The sapphire used as watch crystals is also a ceramic. Engineering wise, ceramics are divided into four sections. Among these “engineering ceramics” are what we will cover today. The rest of the three sections are what we know as ceramics in daily life i.e. tableware, bricks, tiles, etc. Engineering ceramics themselves have many classes and it is not possible for us to cover them all in such an article. Thus we will talk about their general properties and advantages. Unlike earthenware (which is comparatively brittle), engineering ceramics are made of very pure materials. These pure ingredients ensure the needed properties can be produced consistently. Usually the ingredients are oxides, carbides, nitrides etc. Most of which are compounds of metals with oxygen, nitrogen, carbon or others. For instance, Rado states that (http://www.rado.com/files/BXMediaPlusDocument9376file.pdf) they are using zirconium-oxide or titanium carbide for some of their watches. Which are both excellent ceramics.

Engineering ceramics are extremely hard. They are the hardest class of materials known. So scratching a ceramic watch would not be much of a concern. They are usually more than three or four times harder than stainless steel. The high-tech coatings on watches are essentially ceramics. Actually tools made of ceramics are being used to cut metals in mills or lathes. When used properly, they have much longer lives than conventional tools. Related to their hardness, they are good in terms of wear resistance, which is the loss of materials that are in moving contact for long periods of time. This is why rubies are used as bearings in watch movements (21 jewels anyone?). They maintain a smooth surface and low friction for a long time. Thus, thanks to ceramics, mechanical watches can run for years. And their usage on watch cases ensure far less scratches on our beloved timepieces. Hublot has recently developed a ceramic/gold composite, which will hopefully make gold much harder.

Ceramics are also rather light, usually ranging from 2 to 6 g/cc, many of them being around 3 g/cc. They are much lighter than stainless steel (8 g/cc) and titanium (4.5g/cc). They are around the same density as aluminum (2.7 g/cc). This low density together with high hardness makes them very desirable for many aerospace and military applications, such as lightweight layers of armor that break up incoming projectiles or themselves are designed to break up to disperse the energy of a high velocity impact. Thus ceramic watches are very light and somewhat bulletproof too!

Ceramics also have very high strength but with one big defect. That strength only comes under compression. Under compression, they can bear very high loads, strengths ranging 1000 to 4000 MPa. Titanium, that we consider as very strong material, only has 1000 MPa. 4000 MPa is unheard of in any metal. However that’s only in compression. In tension (think flexability) the strength of ceramic falls as much as 15 times, which makes them useless for many applications. Metals on the other hand have very little differences between their tensile and compressive strengths. This ceramic “Achilles Heel” is mainly due to the low ductility and toughness of ceramics. They just break when you hit them hard. If only they had been tougher, they could have been the best materials in the world for almost all applications. This low toughness means you should protect your ceramic watch from impacts, or it can shatter. This is why old stone structures are made with many arches, the arch makes sure the loads are compressive in the nature.

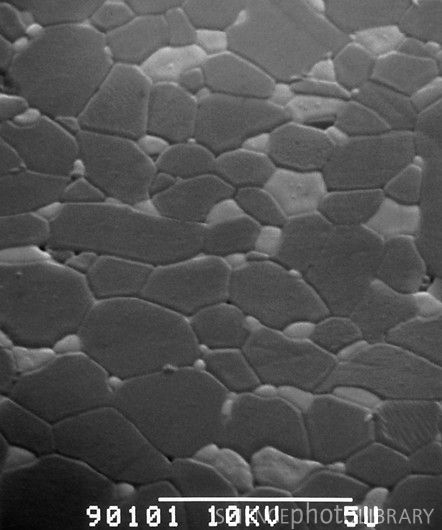

Low toughness is caused exactly by what gives them their high strengths – atomic bonds. Actually atomic bonds are responsible for almost all the properties of all materials. Metals have “metallic bonds”. They are low in strength, but not directional. Thus, a metal atom can bond with other atoms at any angle. This makes them ductile and tough. Ceramics have “covalent” and “ionic” bonds. They are very strong, but directional. (It is actually much more complicated than this, but we are simplifying). Being directional means it is hard to move an atom around another, thus ceramics are not malleable. Composites are mostly a way to solve this problem, to be covered in another article.

Engineers and scientist have worked for years to make ceramics tougher. And one interesting solution is “Zirconia Toughened Alumina” and “Yttria Stabilized Zirconia.” It is a special class of ceramics. When the ceramic is breaking under stress, it microscopically swells at the crack and stops the crack from growing. Thus improving the toughness. Still, their toughness is low with respect to metals. If you had a watch made of such ceramics, they would be much more impact resistant than usual ceramics watches.

Their stiffness is high to very high, which is as we stated in the titanium article, is mostly irrelevant for a watch case, but can be important for movement parts. Recent use of silicon parts in Omega movements are being used owing to their combination of good properties. And, advanced production methods for silicon already exists for very small and precise parts.

One unrelated property of ceramics is their excellent high temperature resistance. Where no metal can function, ceramics retain most of their strength, and thus they are used in jet turbines, brake discs, cutting tools etc. It is completely irrelevant for a watch, but it is such an important property that I had to state it.

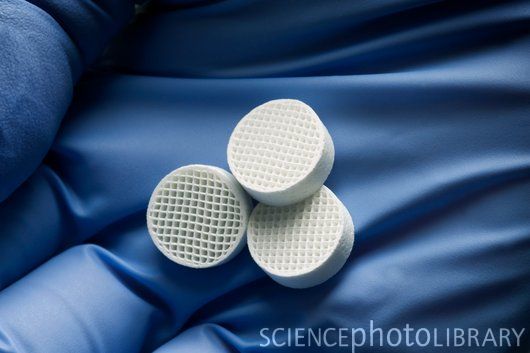

Production methods for ceramics are mainly based on sintering from powders. You can think of it as compacting snow to a snowball and eventually to ice with the heat and pressure of your hand. When a similar technique is used for ceramic powders, a part with the desired shape and properties can be obtained. Very high temperatures are needed to consolidate the powder to a near full-density state. This method is also used for metals. However, I am not aware of any watchmaker utilizing this process for metals. Machining is generally very hard to do for most ceramics. However, there are special ceramics made to be rather easily machined. Glass is also considered a ceramic, and there are “glass ceramics” that are first made as a glass, and crystallized to a ceramic. There are also fancy methods like ultrasonic machining to manufacture precise ceramic shapes.

This sintering method starts by shaping the ceramic powders to a watch case (or other shape), applying lots of pressure and heating to very high temperatures that would melt most metals. Thus, a ceramic case is rather expensive due to the purity of materials and the difficulty in sintering them. It is perfectly normal that a ceramic case is more expensive than a steel or even titanium case. However, it will not likely exceed the cost of a gold or platinum case, as the materials used are not that precious. The raw materials to make ceramic parts is cheap, but the process to make them is expensive. Metals are often the other way around, with precious metal materials being expensive, but the process used to machine them being less expensive.

Like titanium, ceramics are very inert, and will not corrode or cause allergic reactions. Actually what makes titanium so inert is the oxide layer on its surface which is essentially a ceramic. If you scratch it, the underlying metal oxidizes immediately and forms a ceramic layer. Same is true for stainless steel. So, you can guess how inert the ceramics themselves are. Thus you can expect a ceramic watch to never ever rust or corrode. Actually, as long as you protect it from impacts, it`s almost indestructible. A ceramic watch is quite desirable as long as you protect it from impacts. Maybe a metal watch with a ceramic bezel is even better. You get scratch resistance for the bezel and toughness from the metal.

(Note: this article was written to generally inform watch lovers about various materials and is very simplified in order to cover a lot of topics briefly.)