Special aBlogtoWatch Content For Bulgari

Special aBlogtoWatch Content For Bulgari

The dial is often called the “face of the watch,” and there is very good reason for that. For anyone who has ever seen a genuinely beautifully detailed dial – or a horribly made, illegible one, for that matter – the importance of the components’ quality is certainly unquestionable. Complicated-looking dials can be made cheaply, and remarkably simple-looking ones can require hours or days of painstaking work to get right. Beyond case and movement manufacturing, the age-old craft of dial manufacturing is practiced in-house at “Bvlgari Manufacture de Cadrans,” in La Chaux-de-Fonds, Switzerland.

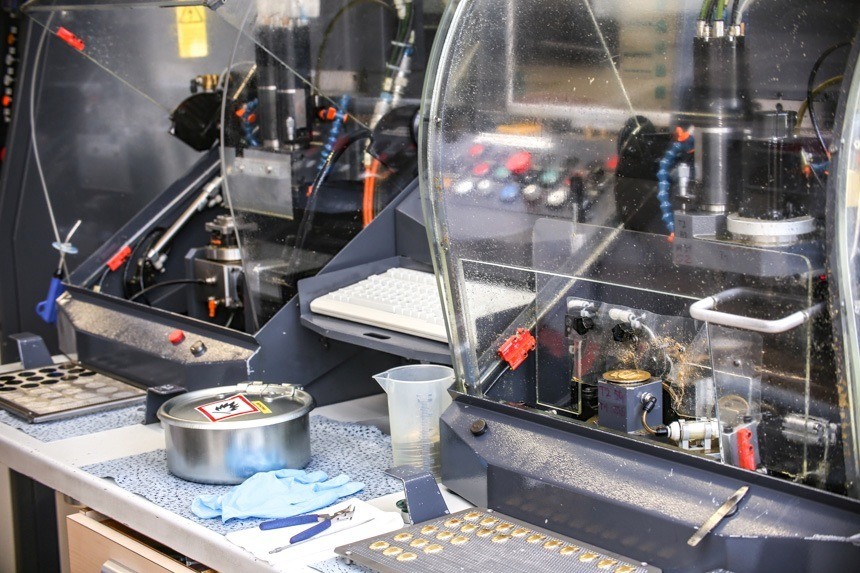

Watch and clock faces have been around for as long as timekeeping machines have been in existence, but that is not to say there have not been tremendous leaps forward when it comes to advancements in manufacturing and decorating techniques. In 2005, Bulgari acquired Cadrans Design SA in La Chaux-de-Fonds. This famous and well-respected facility that specializes in the manufacturing of highly detailed and complex watch dials had already been working on watch dials for Bulgari at the time.

While a lot has been said about the remarkable challenges and unfathomably small machining tolerances in watch movement manufacturing, watch dials deserve just as much attention – if not more! As obvious as it may sound, the dial plays a prominent role in defining the key aesthetic characteristics of a timepiece and is subject to close scrutiny by the wearer. As such, integrating the vast know-how and experience of an established manufacture into Bulgari’s group of production facilities was important, and an ideal way of ensuring extremely high quality standards and constant development.

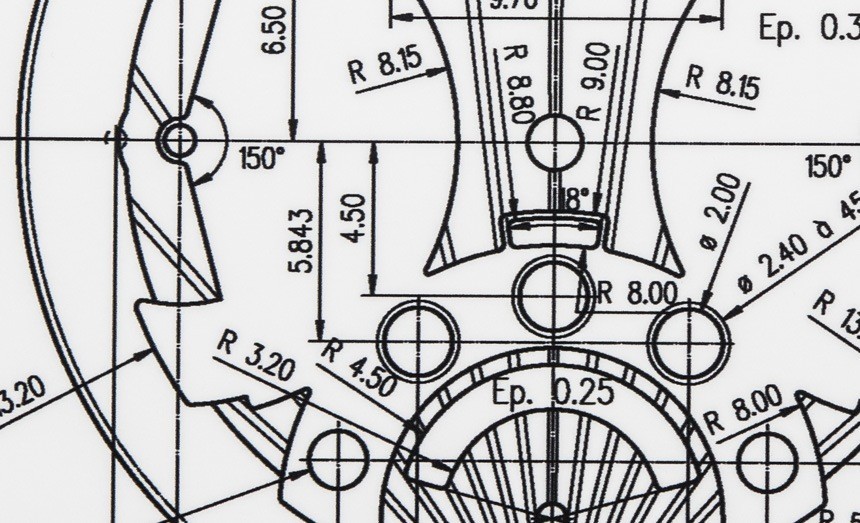

The image just above beautifully illustrates the major steps in dial manufacturing: beginning with design (which in and of itself is a process that requires painstaking work from the leaders, designers, and engineers of the company), the visual plans are translated into extremely accurate engineering drawings which allow for high precision manufacturing.

Right below, you see a detail from such a technical drawing, with exact measurements down to 1/100th of a millimeter, as well as exact angles for all arches and other curved elements of the dial specified. What may seem a straightforward execution of beautiful visual drawings actually is precision engineering hard at work behind the creation of every watch dial ever produced.

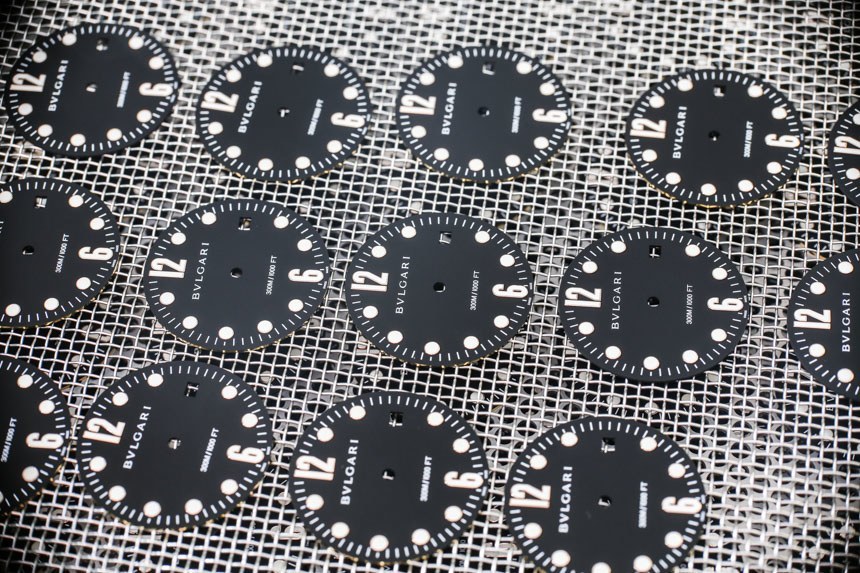

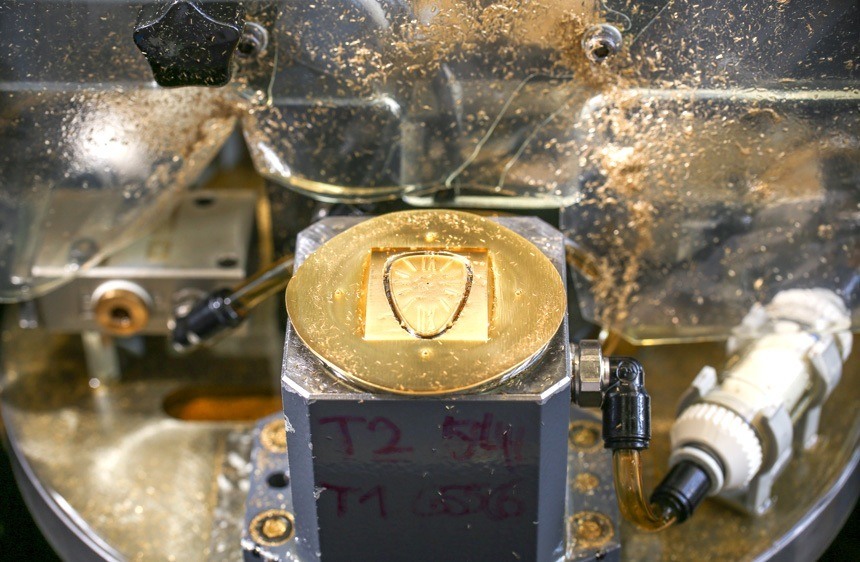

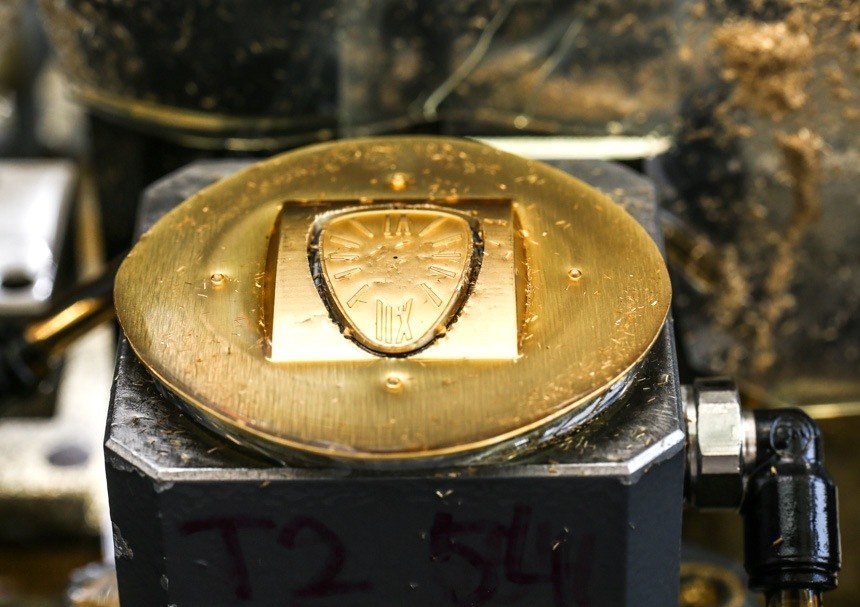

With the drawings in place, actual production can begin, and that more often than not means: stamping. Stamping the brass base of the dial works so well because with today’s more precise tools the basic three-dimensional shape of the dial as well placeholders for indices and the holes for the pinions holding the hands can be produced quickly and efficiently.

Some other components, like the outlines of this swan and the complex geometric shapes of its surroundings, as well as the rounded sockets for the diamonds, all have been cut by numerically controlled cutting machines. This allows the craftsman to get to work on a canvas made to extremely accurate measurements, before setting the dial with precious stones and hand painting it with enamel.

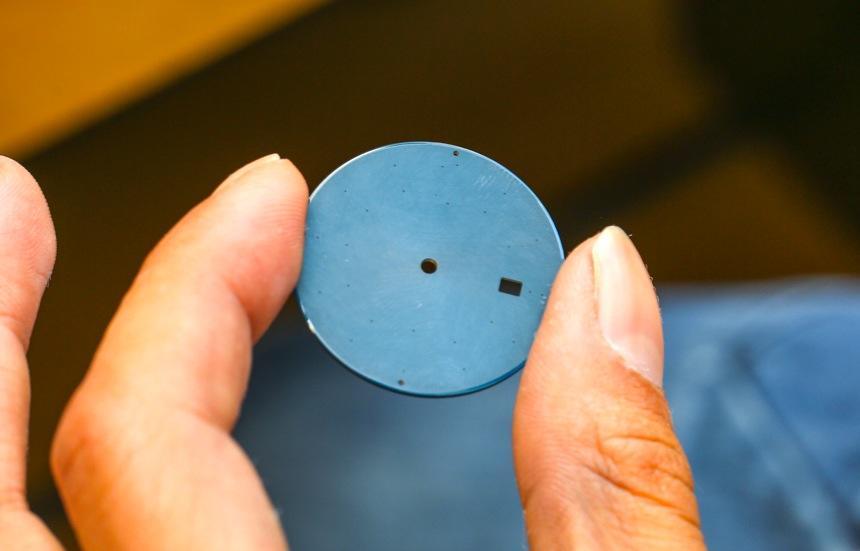

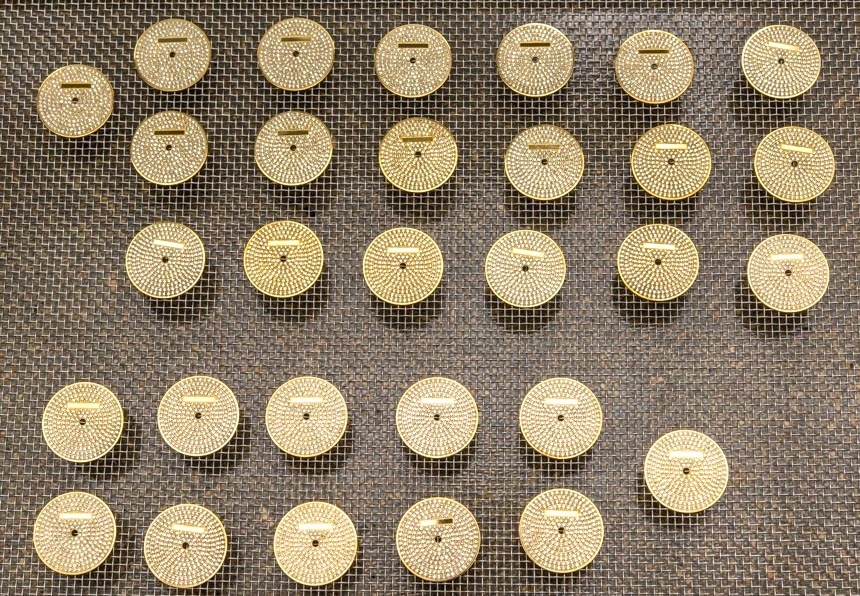

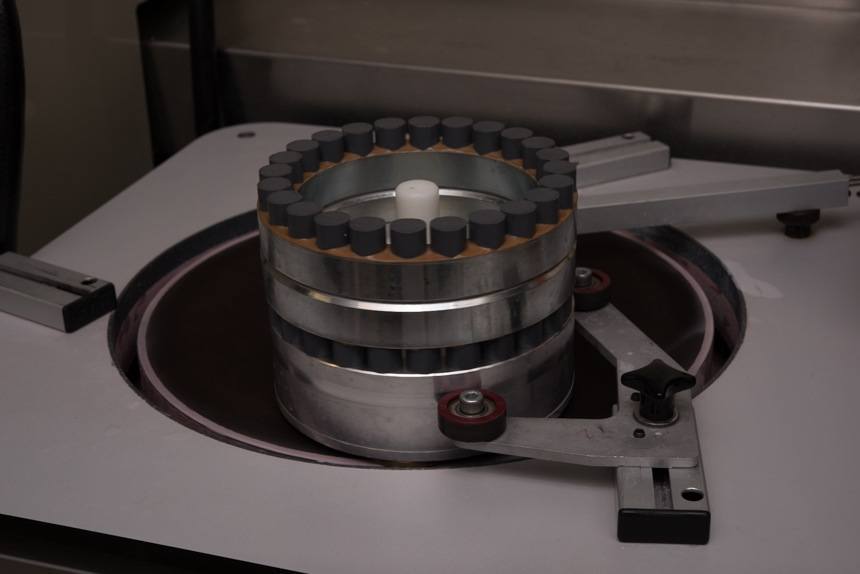

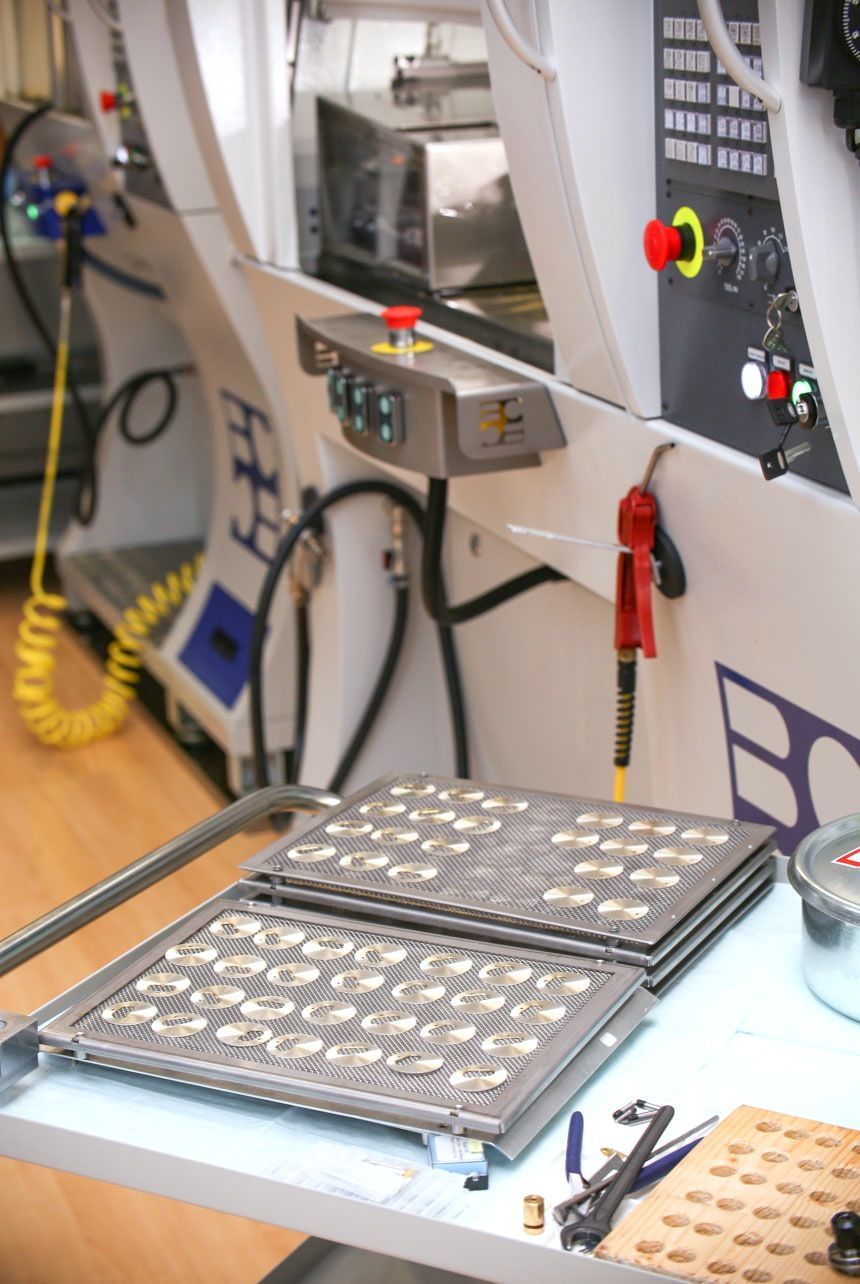

When it comes to dial production, a virtually infinite number of color variations are possible – which is a good and a bad thing at the same time. Hand-painted lacquered or enameled watch faces aside, dials are colored with a technique called electroplating. This includes the fitting of dials onto a tool – that looks like the product of a small clothes hanger and a cactus having exchanged DNA – only for the cut out brass plates to be then submerged into a number of baths – suitable for metal, not suitable for your hand.

The dials must spend a specific amount of time submerged – “specific” meaning precise to the nearest second when it comes to the production of blue dials. Remove the plates from the baths one moment too soon or too late, and the chemical reactions will yield a different shade of color.

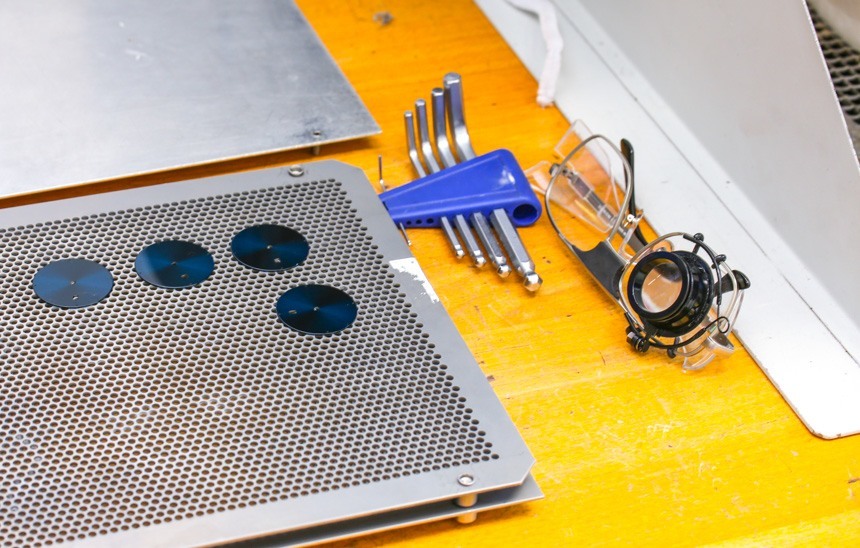

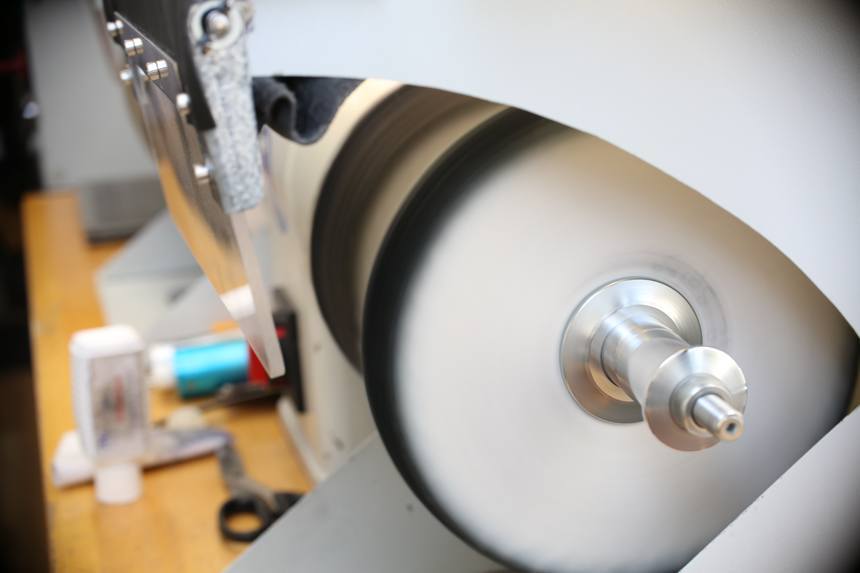

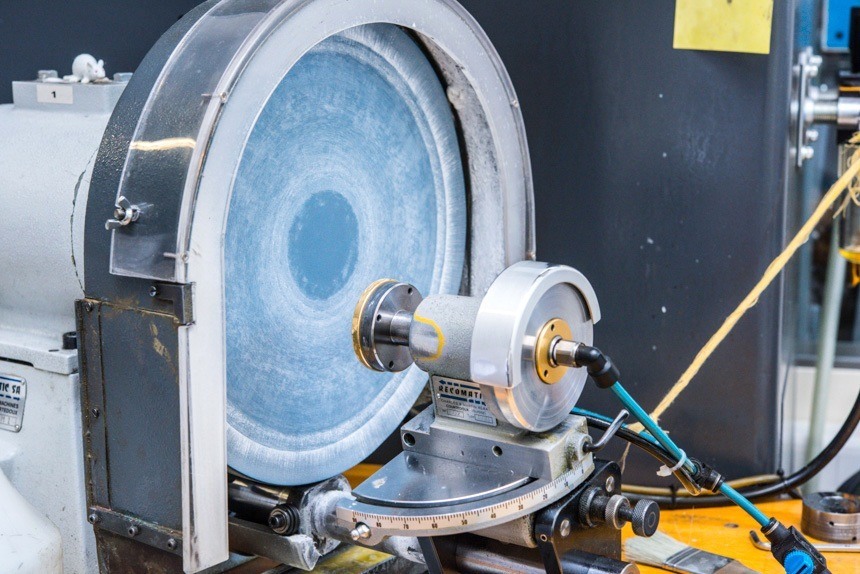

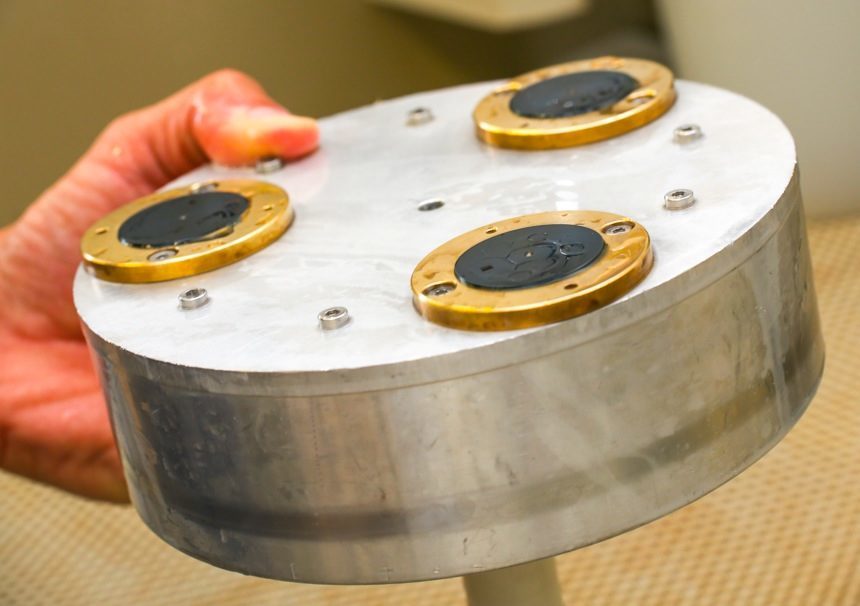

After having plated and inspected the dials to ensure they have reached the desired color, they are cleaned and sent over to hand polishing. Similar to, but in fact much less abrasive and vicious than case polishing, dial polishing is performed by hand to ensure a deep, even sheen that will serve as the backdrop to all prints, indices, and of course, the hands.

Polished individually or up to four pieces at a time, polishing wheels of different levels of abrasiveness are used to remove any hairline scratches that may have occurred during previous steps and then to further smooth the surface. At the end of this painstaking process, the resulting gloss will render this few-millimeter-thick plate of brass or other metal infinitely deep to the eye – a sight to behold before and after the dial is cased up.

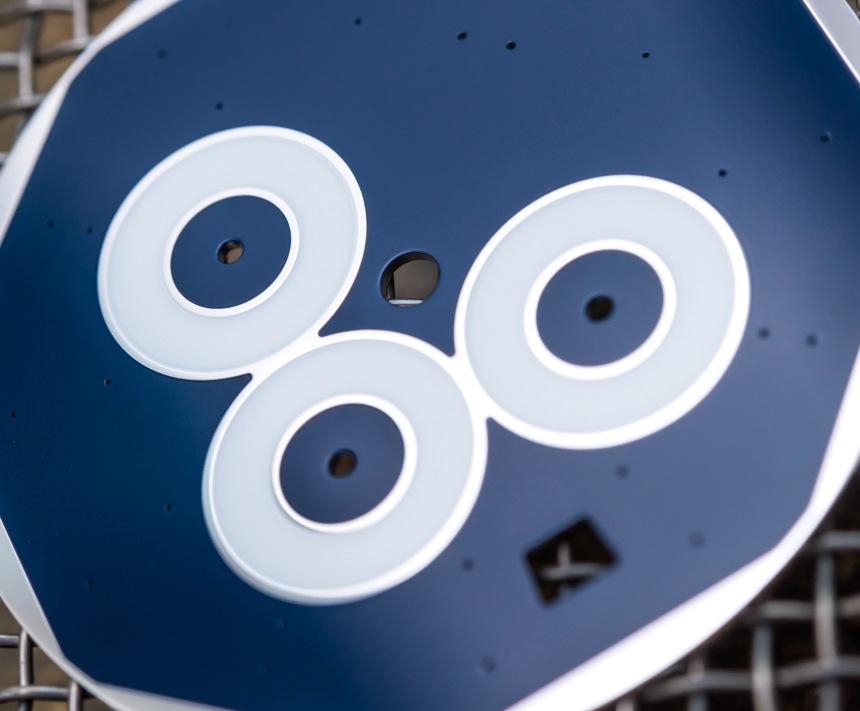

One fascinating detail on watch dials often overlooked – and under-appreciated – is just how legible and sharp print has to be, regardless of the size and type of font used. Surprisingly, such precision printing is achieved through an old technique called “pad printing.” The process involves a trained and experienced craftsman and a hand-operated machine, comprising a metal plate with cutouts for the text, a rubber “tampon,” and a precision holder for the dial.

The craftsman applies paint to the metal plate on the right, and after removing the excess, the dye remains only inside the barely visible cutouts for the text. As the rubber carrier is pressed onto the metal plate by hand, it picks up the paint from the text cutouts – then, as it is gently pressed onto the dial, the text is transferred onto the dial with remarkable accuracy. The key to success here is applying the right amount of pressure to transfer the paint accurately, but to not damage or bend the dial in the process.

Bulgari not only installs indices here in La Chaux-de-Fonds, but is now capable of manufacturing these often infinitesimal components in-house. Always applied by hand, the indices are never glued, but secured to the dial with two or more barely visible metal feet that protrude through the dial. Handling the lacquered, polished, and printed dials requires extreme care, as the slip of a hand or a tool will damage the treated surface and the dial is scrapped!

Watch dials, regardless their shapes and sizes, can be hand-painted with enamel and/or set with diamonds – this rare piece depicting a swan and featuring a large circular cutout to display a tourbillon is just one example. These dials are individually decorated by the same craftsmen and craftswomen, working in what may be the most quiet and relaxing room in the entire manufacture. Two or three of them at most work in this environment set up for efficient but relaxed work, where some of the most complex and high-end Bulgari dials are produced.

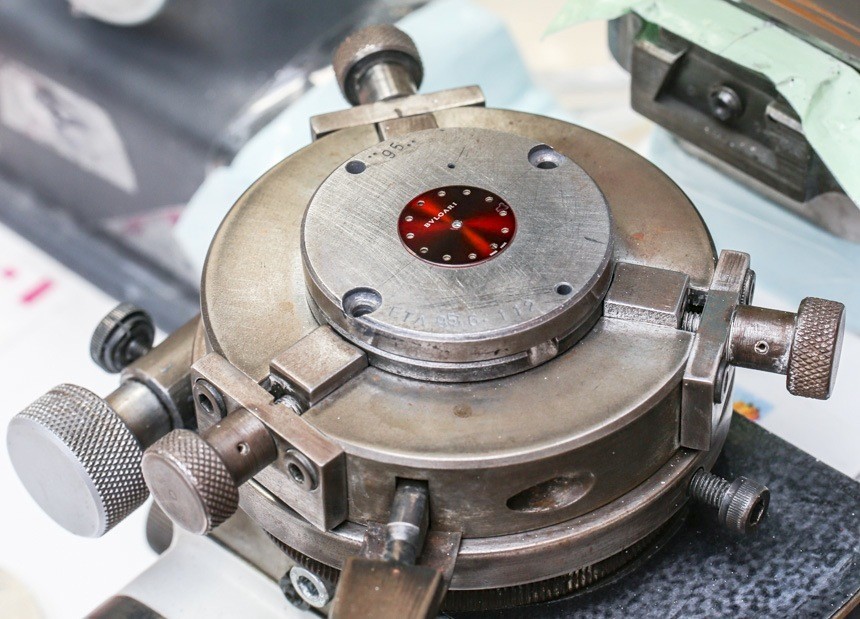

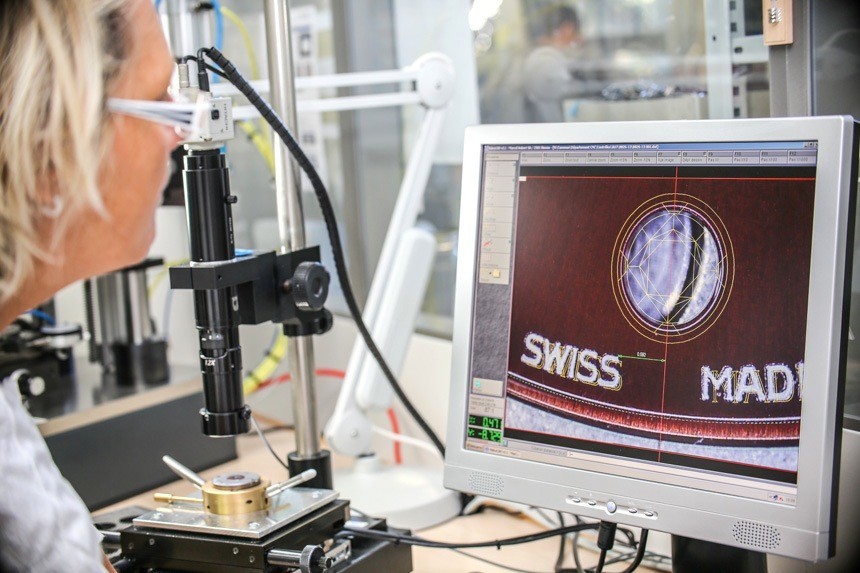

Repeated a number of times through the production process but always being the final step is quality control. Dials are checked under an electro-microscope with the image transmitted by the magnifier being superimposed with an engineering drawing, allowing the actual piece and the desired design to be compared.

Manufactured in-house by Bulgari, the work and efforts of dozens of dedicated people – designers, engineers, and craftsmen alike – results in a component that could stand on its own as a desirable item one would love to behold. And yet, it is just one of the hundreds of parts that make up a finely made Bulgari timepiece. bulgari.com

Sponsored Content produced by aBlogtoWatch for an advertising partner is a form of article content meant to share information about a particular company through the aBlogtoWatch lens. It is not natural editorial content where aBlogtoWatch includes opinions, suggestions, or reviews. Sponsored Content is written by aBlogtoWatch for an advertiser without an editorial or opinionated angle and is meant to convey facts and media in a way that helps advertising partners share insights and views into their brands and products.