Sponsored post presented on aBlogtoWatch by advertiser

Sponsored post presented on aBlogtoWatch by advertiser

Watch company archives have been thoroughly mined over the past years for inspiration from the 1950s and 1960s, with virtually no iconic dial left un-reissued. One category of neo-vintage design left unexplored, however, is the enamel dial — a craft that elevated the watch dial to the level of fine art in the 1950s.

The enamel dials made by Rolex in the mid-20th century are among the rarest and most valuable in the world— and also the most unattainable. Until now.

Ematelier, a modern master of the enamel arts, has developed a way to pay homage to these masterpieces. However, they are as difficult and time-consuming to create as the originals. “This concept and these dials are certainly not for everyone,” says Ematelier’s Alex Landa. “Our clients to date have had a strong affinity specifically for watches with enamel dials and for rare and unique pieces. These bespoke dials originated from custom requests, and have since been driven by the desires of our customers.”

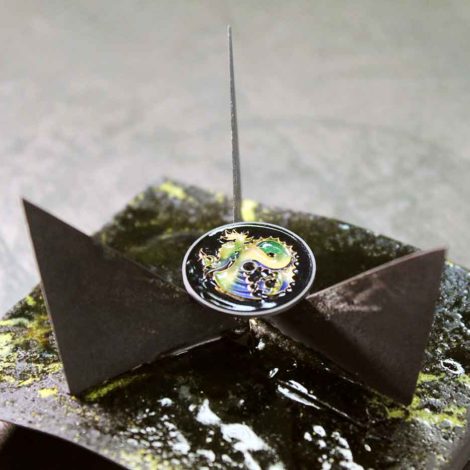

The 1950s represented the heyday of cloisonné enamel dial art, but that does not mean the dials were being churned out in large quantities. The few brands making them at the time – Rolex, Patek Philippe, Vacheron Constantin, and Omega, for example – only produced a few hundred in total during the 20 years they were being created, from the late 1940s to the 1960s. Few artisans were capable of producing them. Rolex worked mainly with Geneva enamel artists Charles Poluzzi and, occasionally, with Stern Frères, and in particular an artist named Nelly Richards. The primary motifs were Viking boats or caravels, maps, peacocks, Neptune, and dragons.

Christie’s auction house sold a piece with a Neptune dial made in 1953 for CHF 609,000 (about $630,000) at a Geneva auction in 2011, and a similar one with a map motif at a New York auction for $425,000. Phillips sold a reference 6085 with a dragon dial for $676,700 at a Geneva auction in 2016 and a similar piece at a Hong Kong auction a year earlier for $750,000.

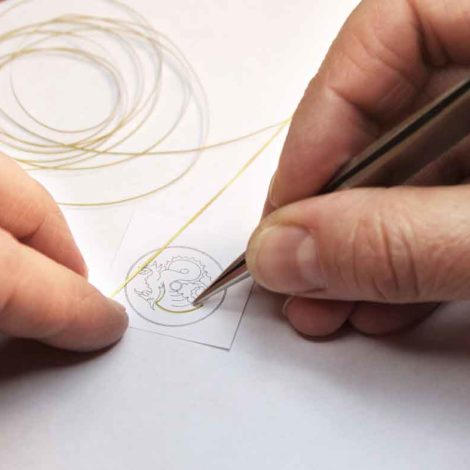

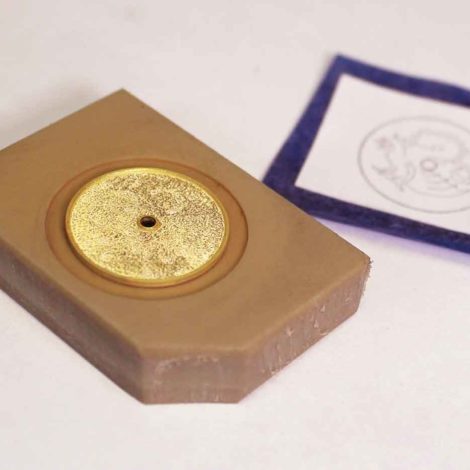

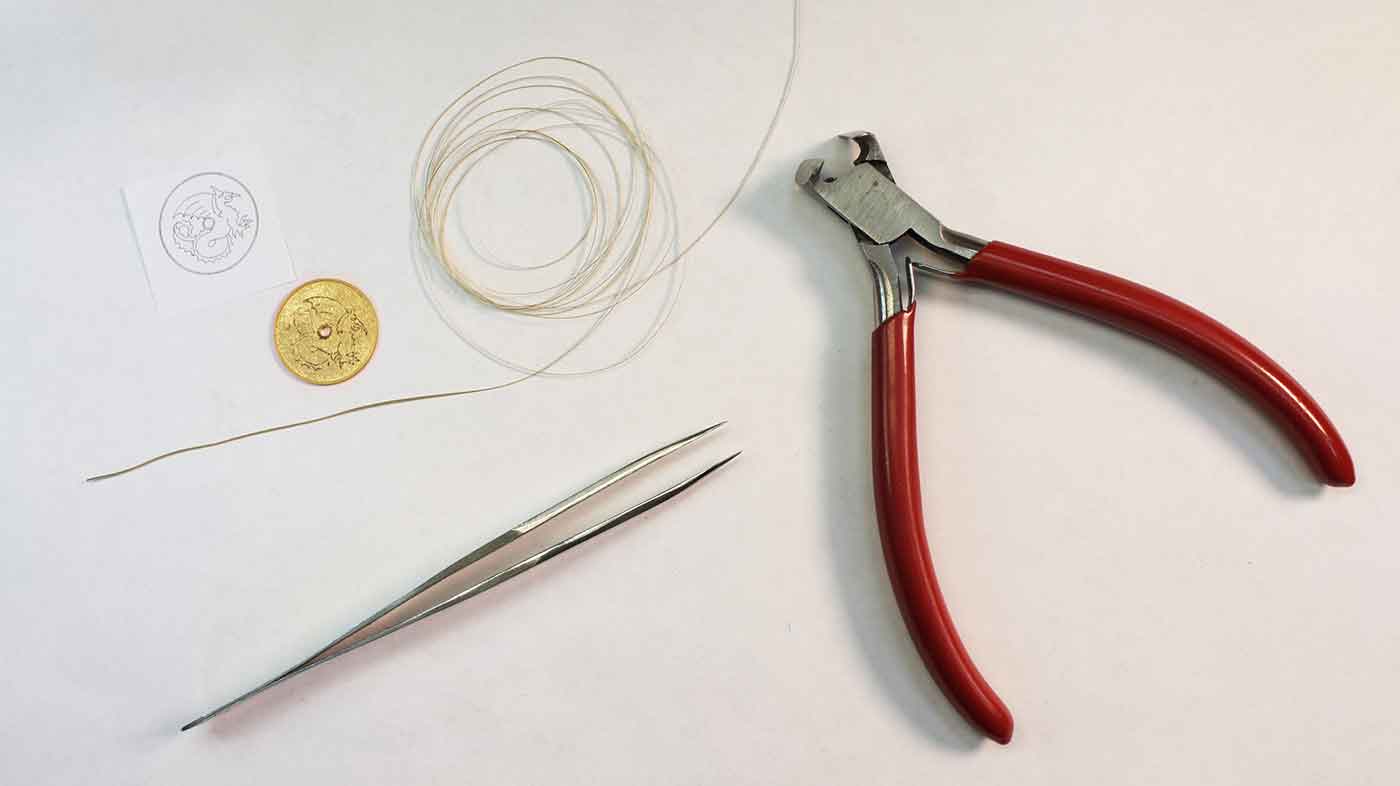

Each dial was made individually by a single craftsperson in the cloisonné style. Cloisonné means “partition” because the technique involves placing thin gold wires on a dial to separate each enamel color that forms the composition. The spaces within each cloisonné are filled with enamel powder, and each color is fired separately in an oven at 800 degrees Celsius. But the dials often don’t get to that point. Every time a dial is fired or polished there is a high possibility it will crack, change color, or have undesirable marks. The rejection rate in cloisonné enameling is extremely high.

Reproducing them today is no less arduous. Ematelier has meticulously preserved the methodology, artisanship, and quality level of the originals, and has gone even further: The enamel is mirror-polished.

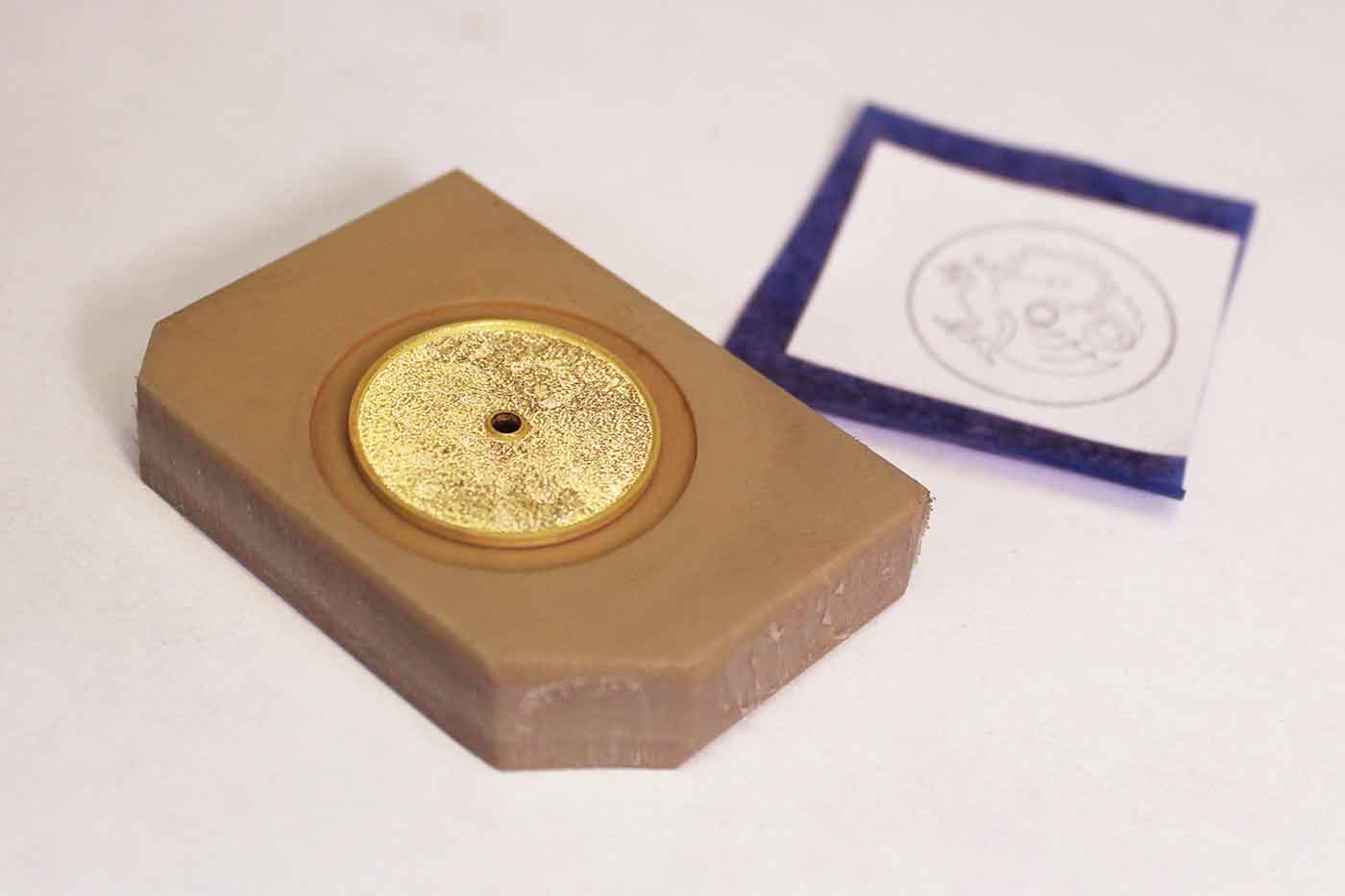

One of the hardest parts was to determine which type of modern Rolex watch would be best to use for the enamel dial. Ematelier decided on the Datejust 41 because it offered a large dial. For enamel, you want as much real estate as possible because the dials are so intricate. The aesthetic of the watch is similar to the vintage watches, as well. The enamel dial is much thicker than the original Rolex dial, so with the help of a Rolex-certified technician, the calendar movement is carefully removed, ensuring that it can be easily put back if needed (all calendar parts were returned to the owners). The process involved complex engineering to make sure that the new enamel dial perfectly attaches to the movement and flawlessly fits into the case. “It was certainly an effort,” says Alex Landa, owner of Ematelier.

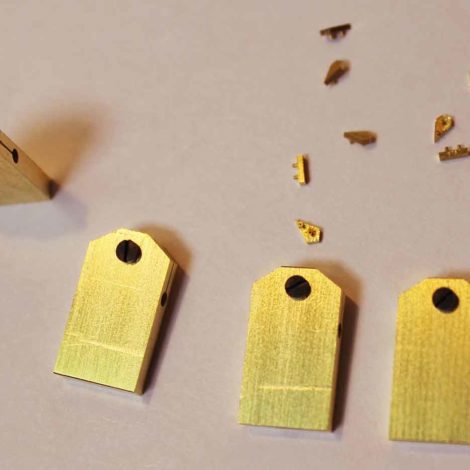

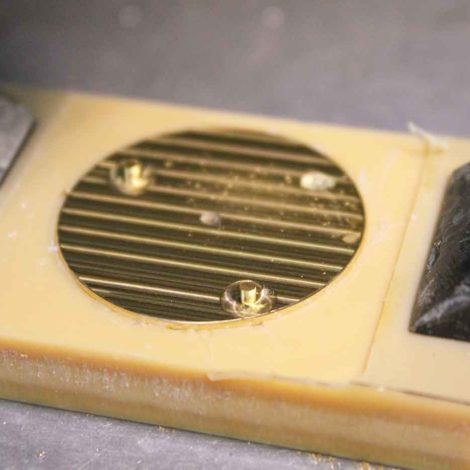

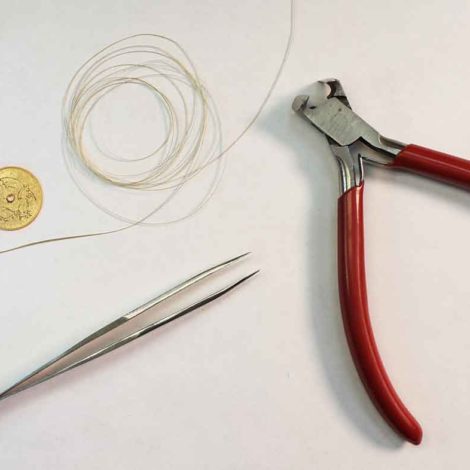

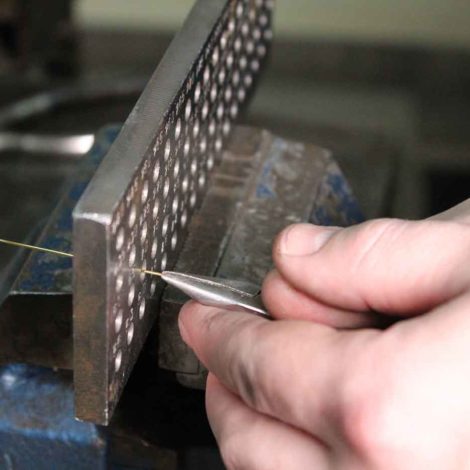

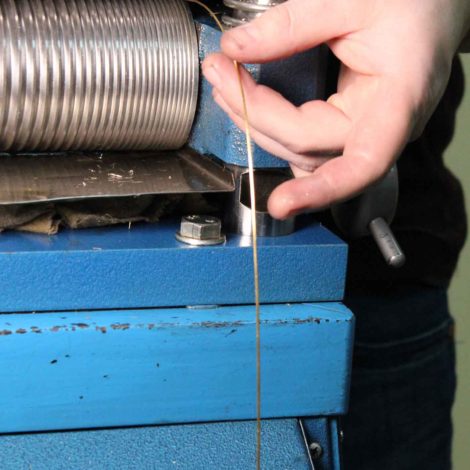

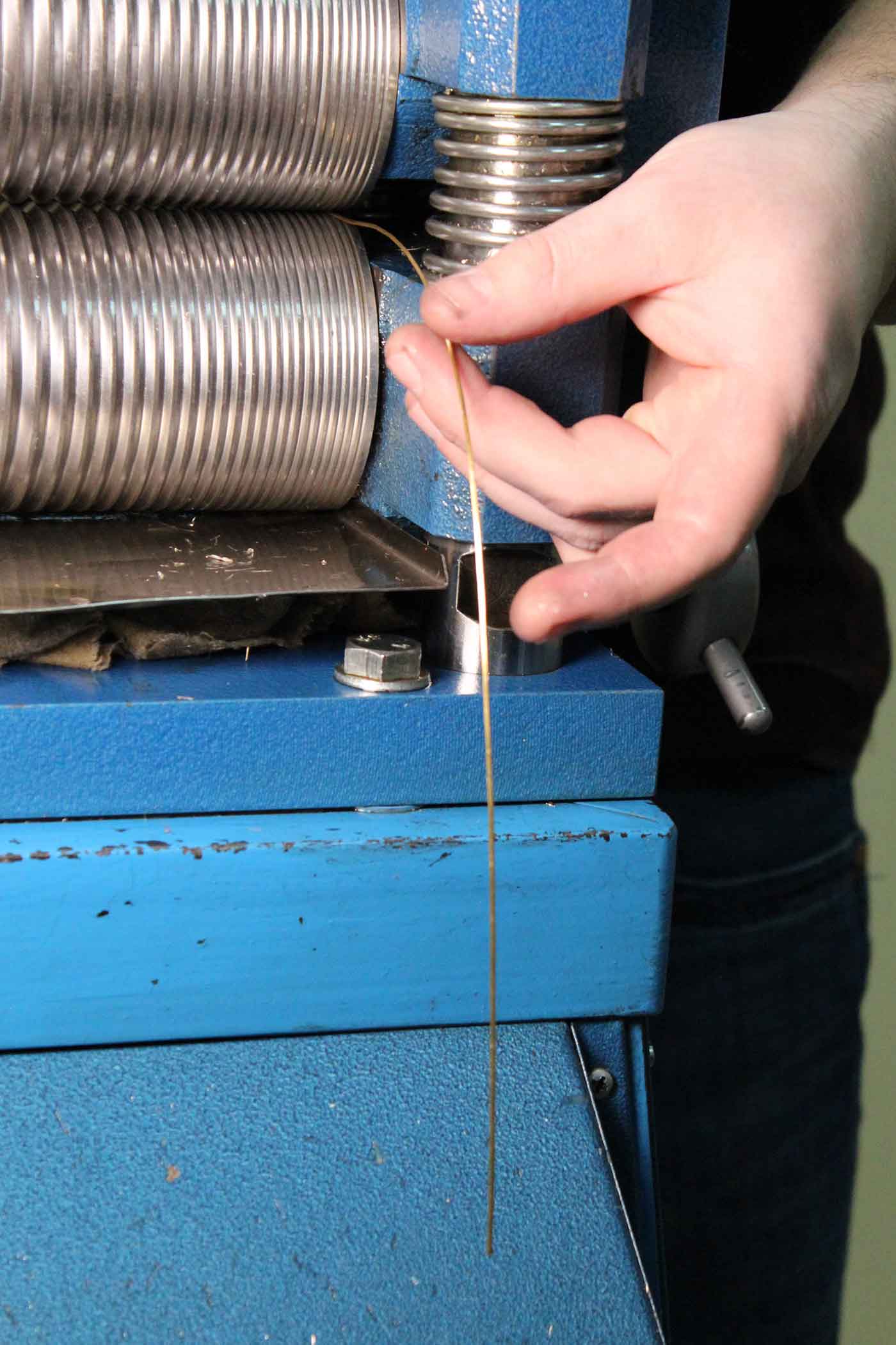

All dial components and finishings are crafted in-house — casting and machining 18k gold plate, rolling 0.07 mm cloisonné wire, creating gold indices, polishing, and assembly. Once the gold plate is prepared, the enameler starts working. They carefully attach cloisonné wire to the plate and start filling the spaces with transparent, opaque, and opalescent enamels in multiple colors. The dial undergoes multiple firing in the kiln at 800°C. After that, the complex and delicate polishing stage starts.

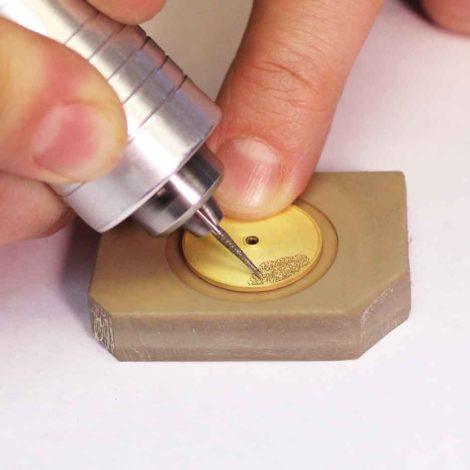

“This is extremely complicated,” says Landa. “On the one hand, you have to create a perfectly flat mirror surface and eliminate all bulbs and cavities; and on the other, you have to be very careful not to damage the enamel composition. Any wrong move and the dial will have to be rejected.”

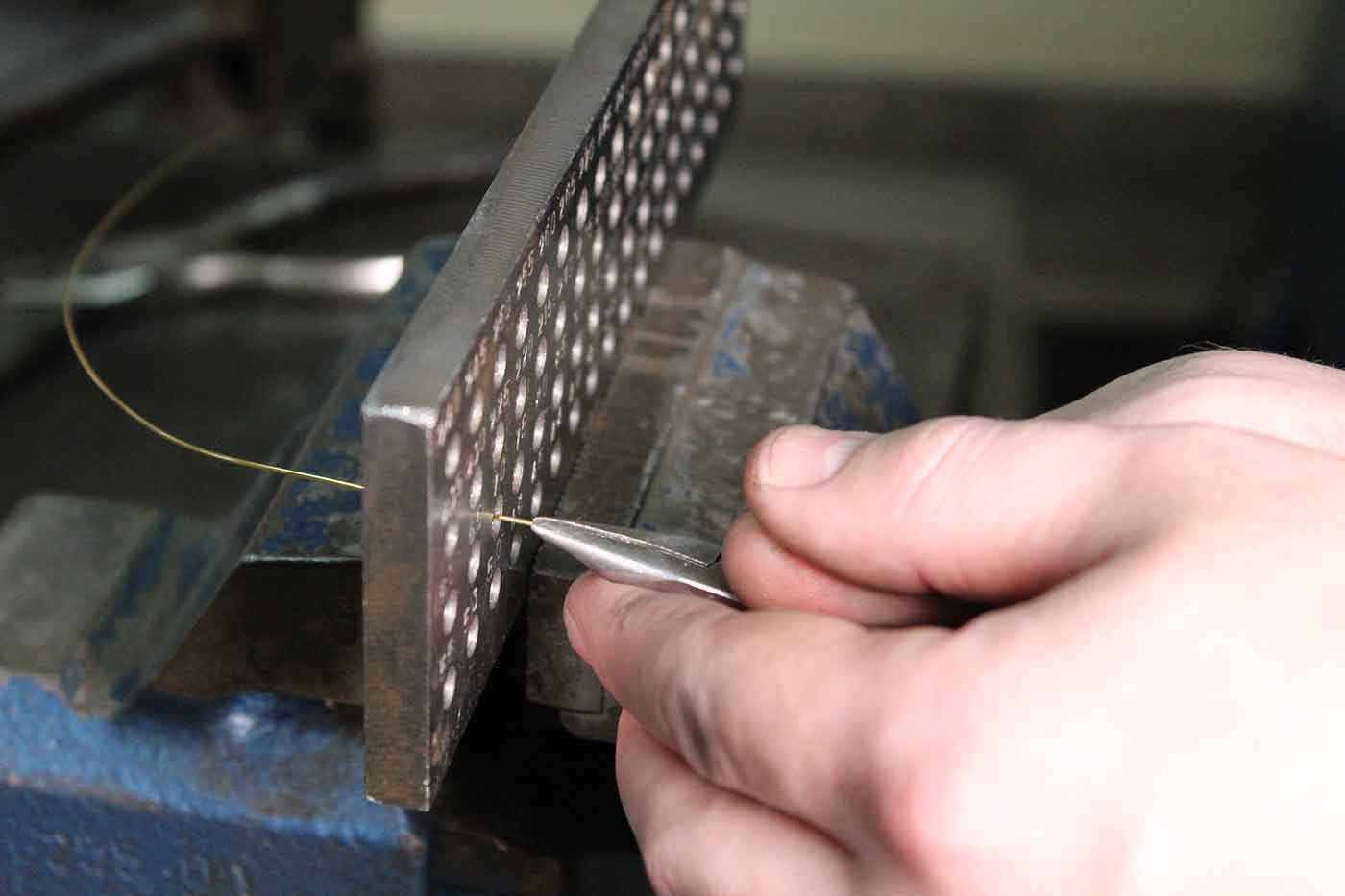

Another significant challenge was the creation of the indices. A proprietary polishing tool was created in-house by Landa’s team to create gold indices with sharp, polished angles. Each dial contains 6.5 grams of 18k gold.

Landa, already known as a master of Grand Feu enamel dials, ventured into the realm of Rolex cloisonné reproductions at the personal and custom request of a client, a dedicated collector who wanted to repurpose his vintage Rolex from the 1960s with a Neptune motif frequently used by Rolex. Four other collectors who saw the final product immediately placed their orders.

“We are proud that the dial is made entirely in-house, and we control the process and the quality,” says Landa. “We are able to provide customers with high-quality, beautiful, and deeply personal custom dials while paying homage to the greats of the 1950s.”

And the price? Quotes are available upon request, as each dial is a handcrafted custom-made piece. But with the cost of a new all-steel Datejust 41, the final product could come to a total of $22,000-$28,000 USD. Be prepared to wait, though. It takes around two months to create one dial, and there is certainly growing demand. For more information, visit www.ematelier.watch.

Sponsored Posts are a form of advertising that allows sponsors to share useful news, messages, and offers to aBlogtoWatch readers in a way traditional display advertising is often not best suited to. All Sponsored Posts are subject to editorial guidelines with the intent that they offer readers useful news, promotions, or stories. The viewpoints and opinions expressed in Sponsored Posts are those of the advertiser and not necessarily those of aBlogtoWatch or its writers.