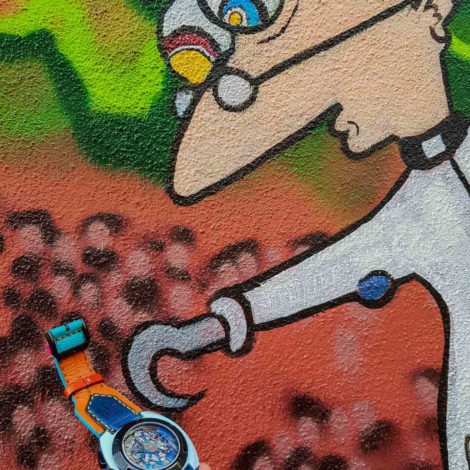

When Texan brand Tockr released its Hydro-Dipped Air Defender this Summer, the reaction was unsurprisingly colorful. But that’s a good thing, these days. In a rapidly evolving retail arena, brands are searching for something that sets them apart from their peers. By creatively importing a decorative technique more common to the automotive industry than our own, Tockr has, quite resoundingly, done that in an aesthetic and technical sense.

As a watchmaker, I am always keen to learn about new techniques firsthand. To my excitement, Tockr invited me to Switzerland for the day so I could see how these unique (and yes, I do mean unique) watches get their new skin. Better still, I was offered the chance to try the dipping process myself. Buoyed by this opportunity, I jetted off to Geneva to meet Serge Pierre Aebischer of Tockr, my guide for the day.

The factory that applies this arresting finish is based in the picturesque town of Vallorbe, about an hour outside of Geneva. Surrounded by the French border, the factory’s humble exterior belies the wealth and gob-smacking variety of activities within.

We were greeted by the director of TEC Group, Arnaud Faivre, a gleeful man with a long and fascinating history in the watch industry. Serge and Arnaud go back a long way. Throughout their time as friends and colleagues, they have worked with a who’s who of watchmaking and been involved in the sale, development, and design of more innovations than I could count. I used to think that the most lethal weapon in the watchmaking industry was a steel Omega Ploprof wielded by a madman, but I think I might have to replace that with Faivre’s phone book dropped from a great height…

The TEC Group comprises 15 companies in all. The facility I visited housed both TEC Ebauches and TEC Arts HD (two parts of the greater whole). As I was guided through several sparse corridors, and large, seemingly bomb-proof doors, the scale of the operation began to dawn on me. I had expected a small team of specialists beavering away in relative isolation, but I couldn’t have been more wrong.

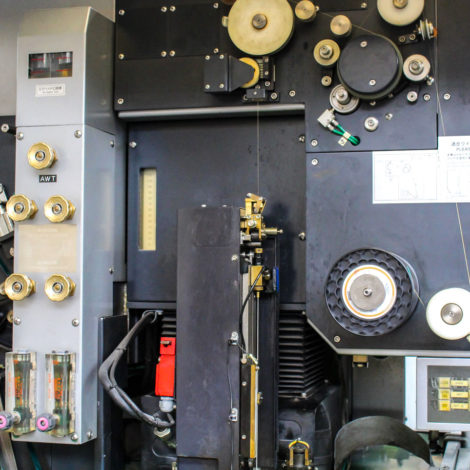

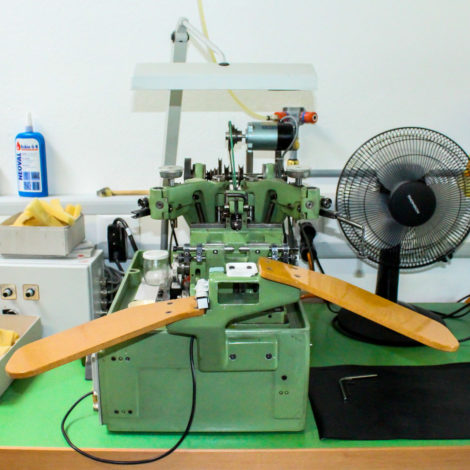

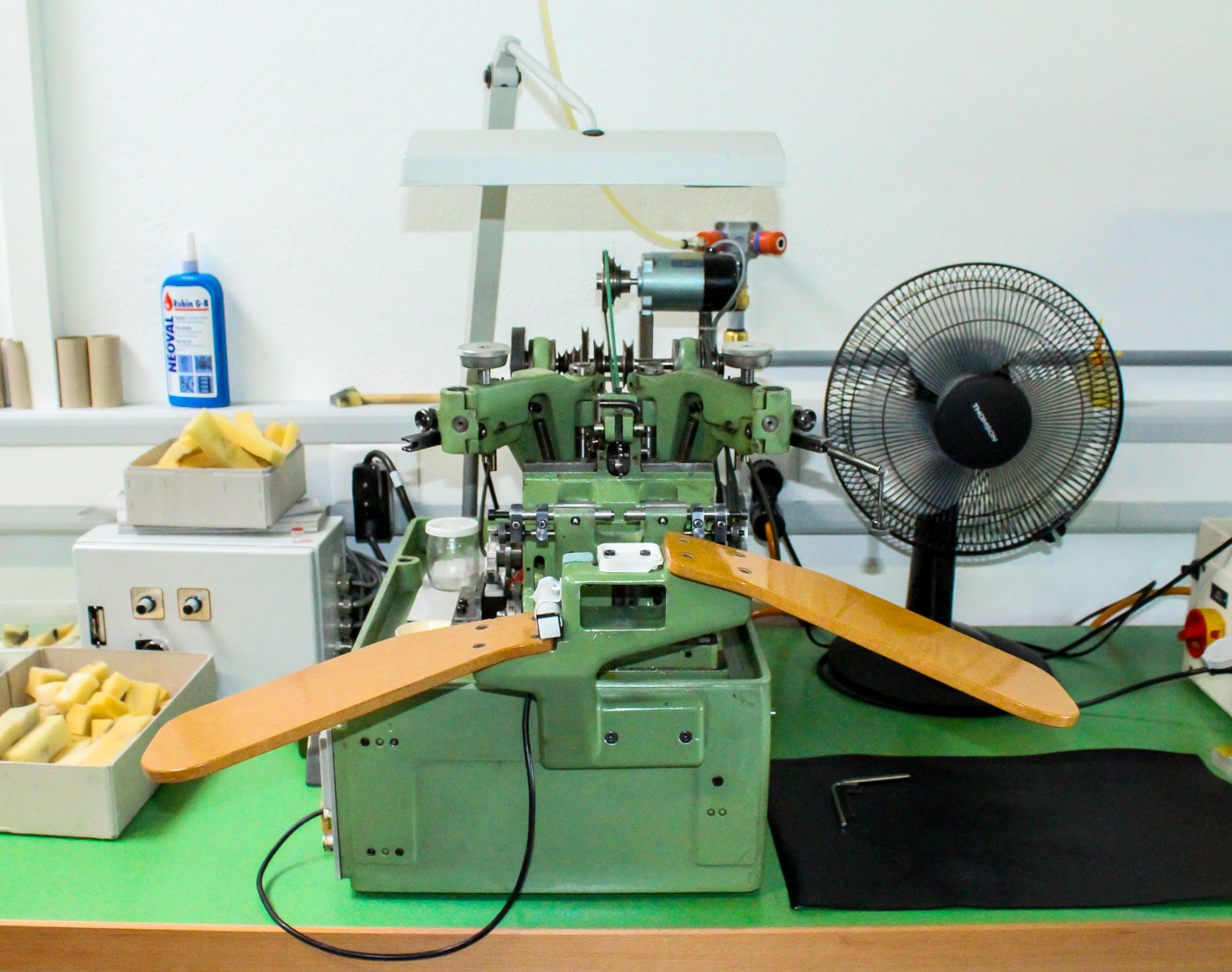

Around 30 CNC machines greeted us on the main factory floor. These machines run day and night, constantly crafting all manner of components. The capacity of TEC Ebauches stunned me. The volume and breadth of their production capabilities are truly breathtaking. Not just that, but learning the number of major Swiss brands that employ the company’s services for anything from pinion cutting to mainplate decoration astonished me. While it doesn’t manufacture mainsprings or hairsprings, TEC Ebauches is pretty much a one-stop-shop for picking up whatever slack there is in a brand.

I hadn’t even reached the TEC Arts HD area or lain eyes upon the Hydro-Dipping machines, and I was already convinced that the wild passion of Faivre and the creative enthusiasm of Aebischer were a perfect match. The marriage between Tockr and TEC Group was making sense as we stepped into the room where the magic happens.

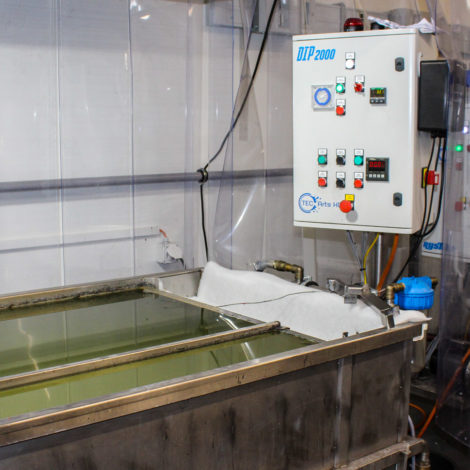

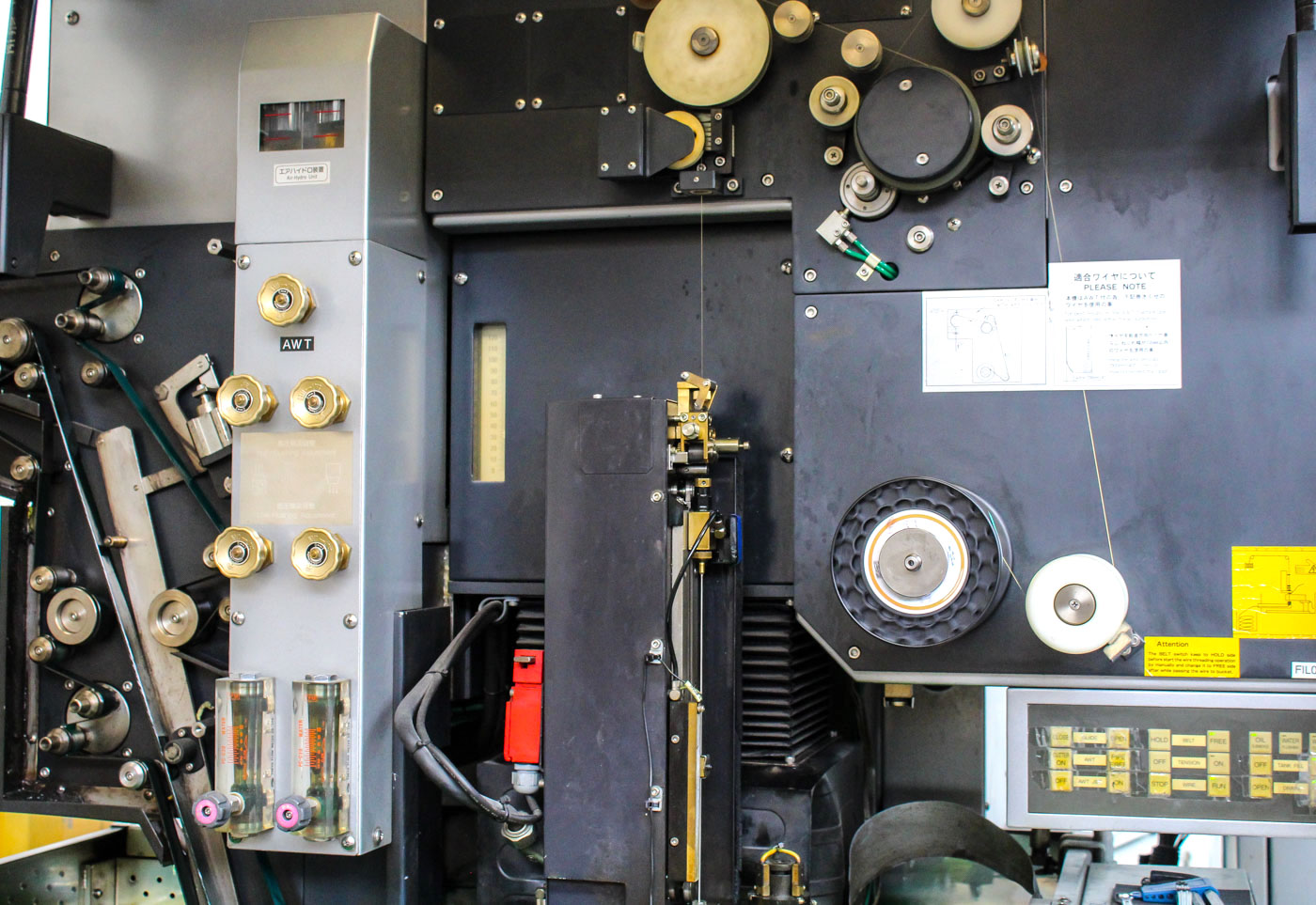

Forgive the hyperbole. While there are not, in fact, wizards running the Hydro-Dip tank, witnessing the process does leave you feeling like you’ve just watched a magician pull a rabbit from an egg cup. I’ll break down the process step-by-step, but let me just say this: It is as weird as it sounds. I’ve been lucky enough to be around some pretty special machinery in my life, and I’ve seen some crazy material feats accomplished in watchmaking. I even had the opportunity to cut a metal desk to ribbons with the edge of a magic gold bezel in the Hublot 2 factory in Nyon, which has left me pretty desensitized to this kind of thing. But Hydro-Dipping had me shaking my head in the same way EDM cutting did when I first realized what was happening beneath the oil. It was, in short, a treat.

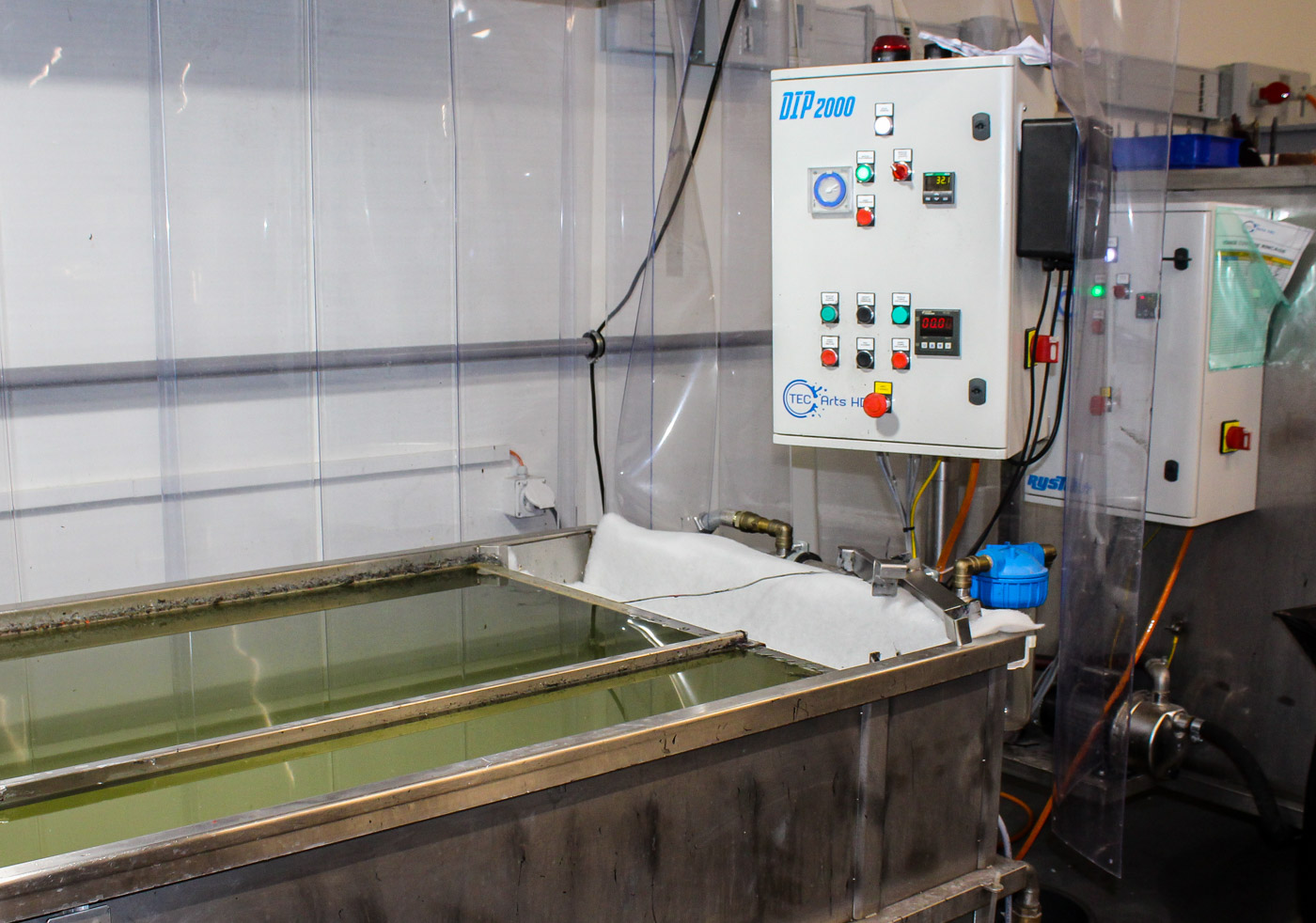

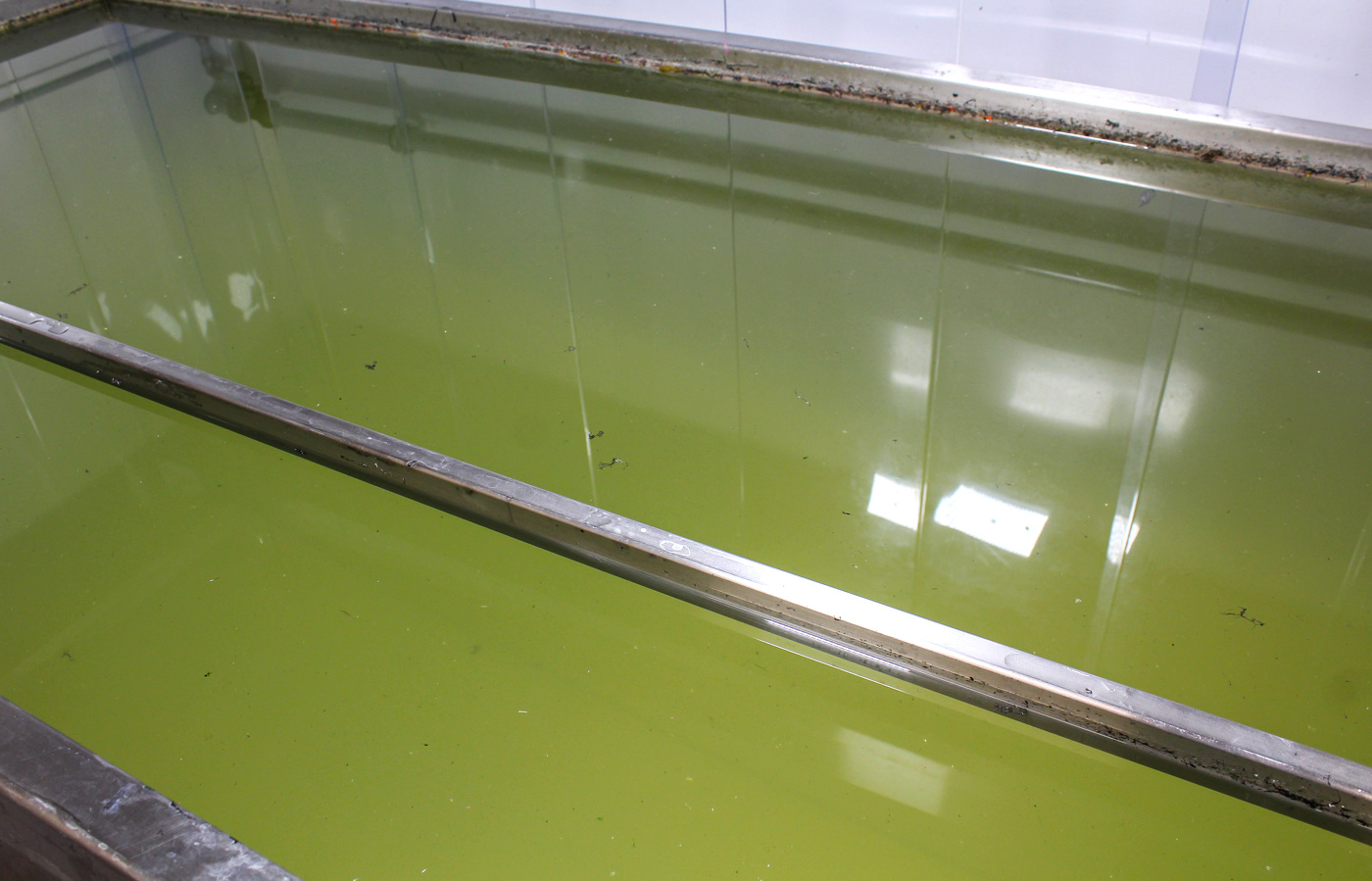

The dipping process takes place in a tank around 2.5 meters wide by 1 meter deep. This tank is filled with nothing more remarkable than water. Crucially, however, the water is heated to 32 degrees Celcius (89.6 degrees in Fahrenheit), which is essential for the process to work correctly.

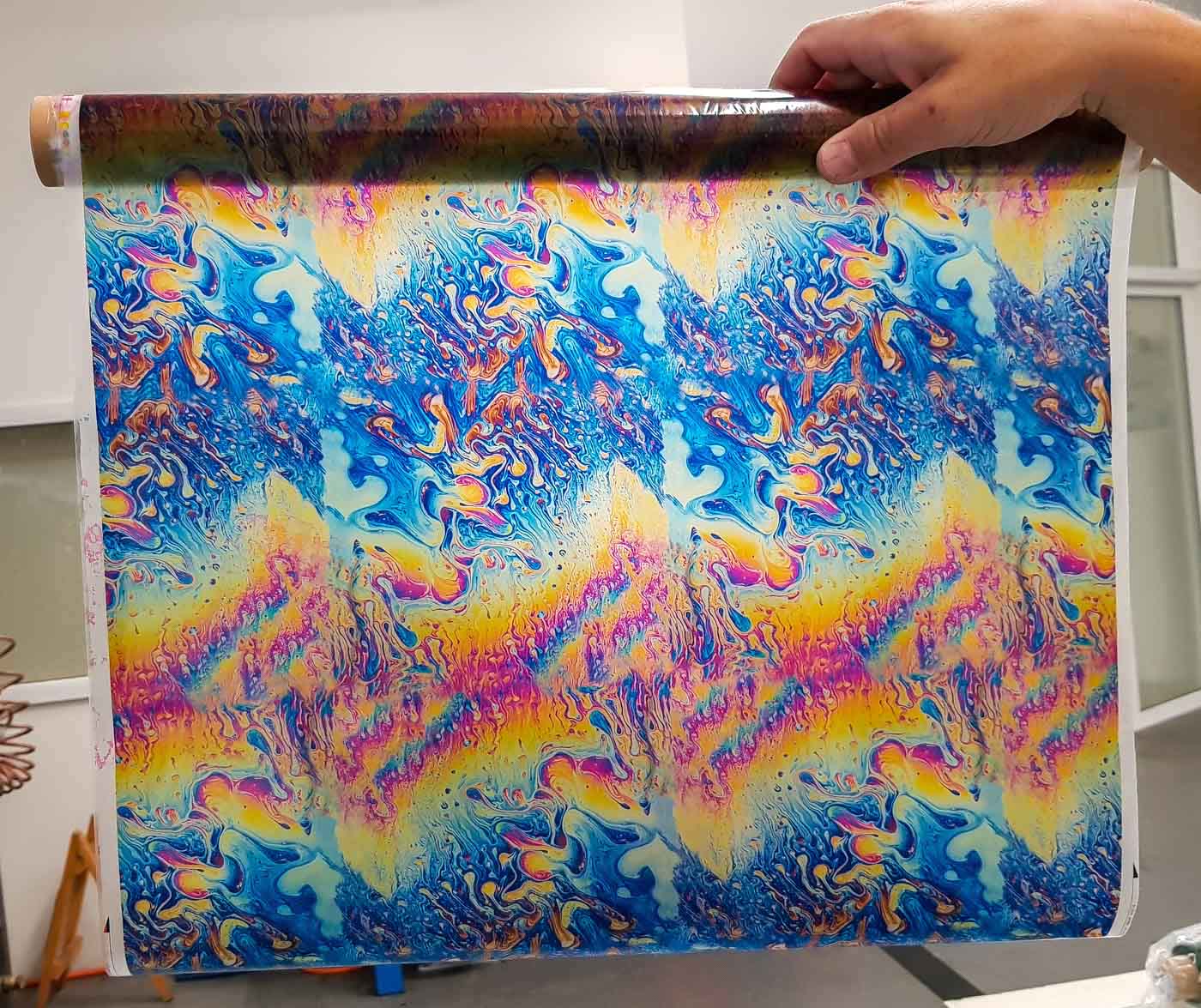

Next, a small piece of printed film around 4 microns-thick is floated on the surface of the water. This film could be decorated with anything you can imagine. If you did so wish, you could have your face, favorite pet, or regular fast food order printed on the film. Tockr and TEC Arts HD are happy to do this for you!

It does not come cheap if just one timepiece is desired (for custom prints, 25 square meters of the film must be produced), but if you want a whole series then the cost of personalization begins to tumble from somewhere around CHF 1,000 for the first 25 m² to a much more manageable amount, depending on volume.

The following step sees an applicator chemical sprayed onto the film. This chemical formula reacts with the film and bonds the design to the surface of the dipped object. But before that can happen, the object (in this instance, a watch case) must be prepared for dipping.

This isn’t as simple as it sounds. Rather than just being thoroughly cleaned, the watch cases must also be finely blasted to remove any surface imperfections, as any kind or burr or wobble in the metal will be noticeably magnified by the dipping process.

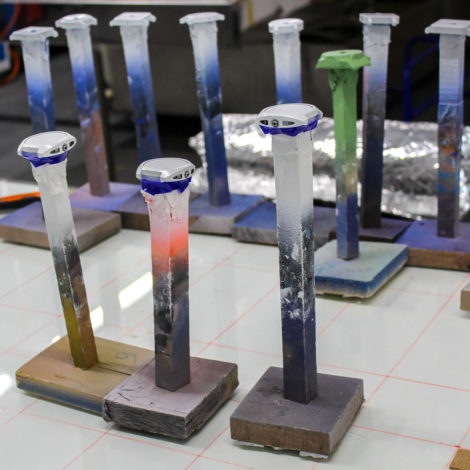

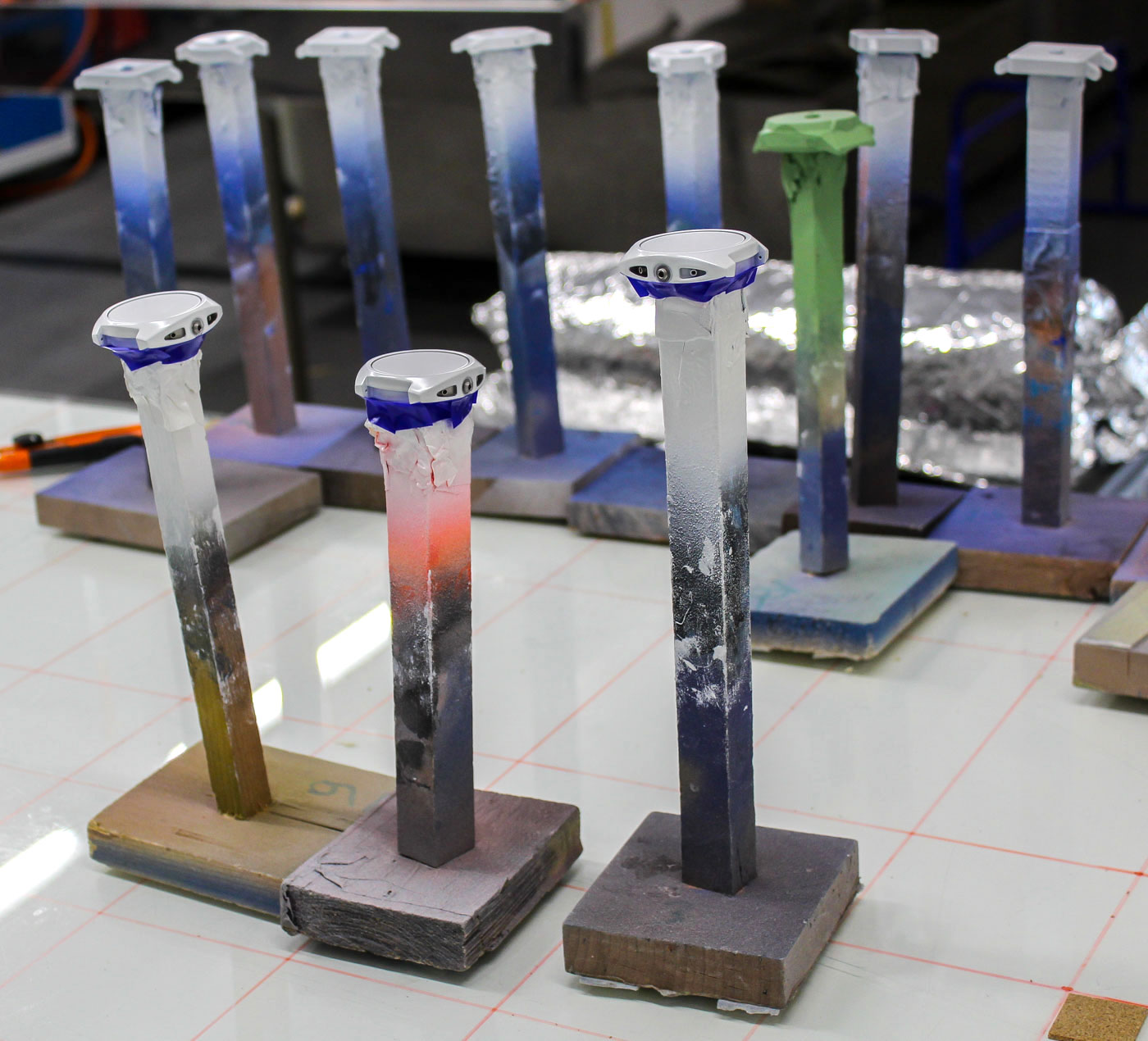

In addition to being smoothed, so too must the watch cases be primed. This is an important step for two reasons. Firstly, because the primer enables the film to adhere to the surface, but secondly, and perhaps more importantly, the color of the primer vastly alters the result.

Several of the standard finishes offered by Tockr on its website rely heavily on the primer for their character. The Tie Dye model on my wrist in the images uses a baby blue base layer (see the case back image above). This color affects the hue and contrast of the watch’s appearance when the film is applied on top of it.

If you check out the Magma model (above), only the black and white of that design are applied by Hydro-Dipping. The orange is the primer, just as in the below image of the two hard hats.

Once the applicator chemical has been sprayed on to the printed film, which is floating on the 32-degree water, the smoothed and primed watch case is ready to be dipped. The watch case should enter at a 45-degree angle, pass through the film, and then be separated from the excess in a swirling motion. And that’s it. As soon as you remove the case from the water the design is in place. You can even touch it right away.

The next step sees the newly-decorated case being washed intensely. For more than ten minutes, powerful jets of water bombard the case, cleaning every trace of the applicator chemical from its surface. The case is then left to dry for 24 hours. Two coats of lacquer are then applied before the case is allowed to dry for a further 24 hours, at which point another two layers of lacquer are applied before the watch is finally cured over 48 hours. It is, apparently, possible to speed up that process (down to as little as 8 hours) when heating the lacquer to 90 degrees Celcius with an infrared lamp, but as time-efficient as that sounds, Faivre assures me he prefers the long-term results of the patient method. And whatever gets the best long-term results is what they do at Tec Arts HD.

One of the biggest questions I have regarding this technology (which I’m sure will be echoed by the watch community en masse) is exactly how durable it is. Aebischer smiles at this question with the expectant twinkle in his eye of a man who has been asked the same thing 1,000 times already.

“Look,” he says, “It is a coating. It is not DLC. It is not bonding to the metal on a molecular level. It is a surface treatment, so yes, you could scratch it if you subject the watch to a massive impact. But it is surprisingly tough. It stays on the case well. Nothing like heat, or sweat, or just time alone will remove it.”

That was what I expected to hear, and as much as I expected. This is a decorative technique and is, of course, vulnerable to material mistreatment. But it is fundamentally strong, resistant, and highly inert. While it is not for everyone (and most likely for the relative few), those who do see the joy and potential in the technology will love it. Having experienced the dipping process myself, I can say that it is fascinating and almost enough to compel me to purchase on interest alone.

If I’m honest, I think one of the smartest uses of this process is actually for decorating internal components, as seen on my (optional) Hydro-Dipped rotor, which can be requested from the brand at the tme of ordering, if you so desire. I only say that because the coating is completely protected from any kind of physical impact, but I wouldn’t want to see it overused. As it happens, I think the rotor is the perfect spot for this kind of personalization, although it is within TEC Arts HD’s ability to Hydro-Dip bridges or mainplates that might be a step too far for my tastes.

That said, I’m the guy who fell in love with the Tie Dye case, so maybe my tastes are more extravagant than I realized. Paired with the custom-made, hand-stitched, multi-leather tapered strap by Oklahoma leather workers Hix, this is, without a doubt, the most eye-catching, conversation-starting, off-the-wall mechanical watch I’ve evet worn. And it’s powered by a 7750. Any technology that can cause this kind of stir while underpinned by one of the industry’s most ubiquitous workhorses is surely worth a look, if only to be amazed. Learn more at tockr.com.