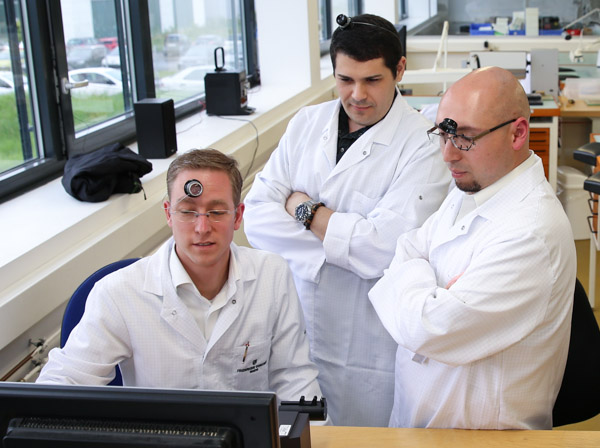

Sitting on the watchmaker’s bench, two things became apparent; that finger condoms (cots) choke the blood out of my fingers and looking through a loupe with just one eye gives you no depth perception when you need it most. For several days I took instruction from a master watchmaker while I and an aBlogtoWatch reader were guests of Frederique Constant in Geneva putting together our first watch movement. It was a thrilling experience, and one that few people will ever receive, even if they pay for it. Unless they go to a watch making school that is.

Technical Director and watchmaker Pim Koeslag is Dutch, and so is Peter Stas, who is the founder of Frederique Constant (with his wife Aletta). The manufacture which also houses sister brand Alpina is nestled (quite literally in the middle) of several famous manufactures in Geneva including Piaget, Vacheron Constantin, Rolex, and Patek Philippe. Pim started working with Peter when Frederique Constant was getting serious about making in-house movements, which increasingly constitute the calibers in their watches. A planned expansion is due for the manufacture soon, and more movements will be in-house made versus sourced from Swiss makers such as Sellita. For Stas, producing movements in-house seems to serve more practical reasons than the marketing-related statements from other brands on increasing the value proposition of their products. In manufacturing, producing things yourself is cheaper, faster, and more reliable. Frederique Constant aims to offer some of the best in-house made movements at the most reasonable prices, and so far they are doing a great job of it with a number of sub $3,000 watches that include their own movements.

So what was I doing at Frederique Constant with a reader, taking valuable watchmaker space? Watch brands don’t just invite people to occupy their production space to play around with watch making. It isn’t something you can pay for, and even company employees and VIP collectors only get access to special outside workshops and classes. We however sat among the other watchmakers during business as normal trying to quickly learn the ins and outs of movement assembly. It was part of a giveaway we did back in December of 2012 where (among other things), I was to join a lucky reader in Geneva and make a timepiece at Frederique Constant. It was a rare treat and doing so was a novel experience for both myself, the reader, and the people at Frederique Constant.

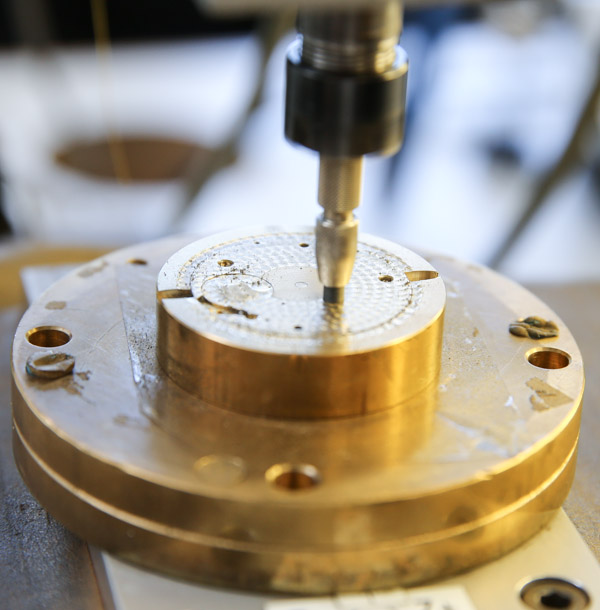

The movement we got to assemble was a Frederique Constant caliber FC-705. The new automatic with date and moon phase that sits inside the 2013 Slimline Moonphase Automatic watch. With just a few days to work on the movement, we admittedly didn’t do each and every step because the entire process simply takes longer than that. However, we did get to experience everything from CNC machining the movement mainplate to final testing and quality control.

The large number of pieces inside of each watch movement means that production delays can be frequent if there is an issue with just one piece. Tolerances are minimal and with size an issue, Swiss watch movements are designed for each piece to fit together snugly. Movements are cleverly designed, something that has been refined over decades and decades, to be machines that can be logically assembled en masse, albeit by trained professionals. That means that there is a certain industrial logic to most movements. Sure, some are unique creations that need huge amounts of tinkering to get right, but in most instances, the design of a movement and its prototyping and testing is much more complicated than the assembly of the completed, industrialized product. Nevertheless, like I said, they are by no means easy to assemble. Watchmaker school averages about four years, and once you are put to the task of assembly, you quickly find out why.

I want to broach a topic that is often left out of conversations, “what is different about an ETA movement versus many in-house movements.” Oftentimes very little. There are only so many effective movement configurations possible. The basic arrangement of movements and their designs are staggeringly similar from movement to movement – though even minor differences require completely different parts. Brands have the ability to design plates and bridges differently, but when it comes down to it, the mechanical watch movement of today is surprisingly similar to that of yesterday. The difference is in the materials used and the techniques to make all the parts. And from brand to brand, like car engines, it is easy to recognize the basic parts of each movement. For that reason I caution people to relax when a brand boasts about a “brand new movement that has been redesigned from the ground up.” Sure, movements can be improved and refined in dozens of ways, but unless new features are added, don’t expect marvelous novelties each time a watchmaker releases something new.