Switzerland hopes consumers will associate the term “Swiss Made” with high-quality, high-design, and forgivably high-prices. Many wristwatch consumers around the world still associate watches with the label as being of higher value. In 2020, the essence of the term is in danger. As applied, “Swiss Made” does not require timepieces to be entirely produced in Switzerland or to use Swiss labor. How might current events such as the COVID-19 coronavirus and China’s poor economy have an effect on both the essence and application of Swiss Made in the near future?

While “Swiss Made,” as a protected term, does indeed apply to a range of products, the primary use of the term is associated with wristwatches. In fact, my understanding of relevant Swiss law suggests that, while timepieces have a series of specific rules as to how and when “Swiss Made” can be applied, the law is more open when it comes to the “Swiss Made” label as being applied to other products. This is not surprising because it is, in fact, the Swiss timepiece industry that more or less crafted what “Swiss Made” means in a modern sense. More so, my understanding is that, in a commercial sense, “Swiss Made” is far more important to the watch industry than any other Swiss commercial vertical.

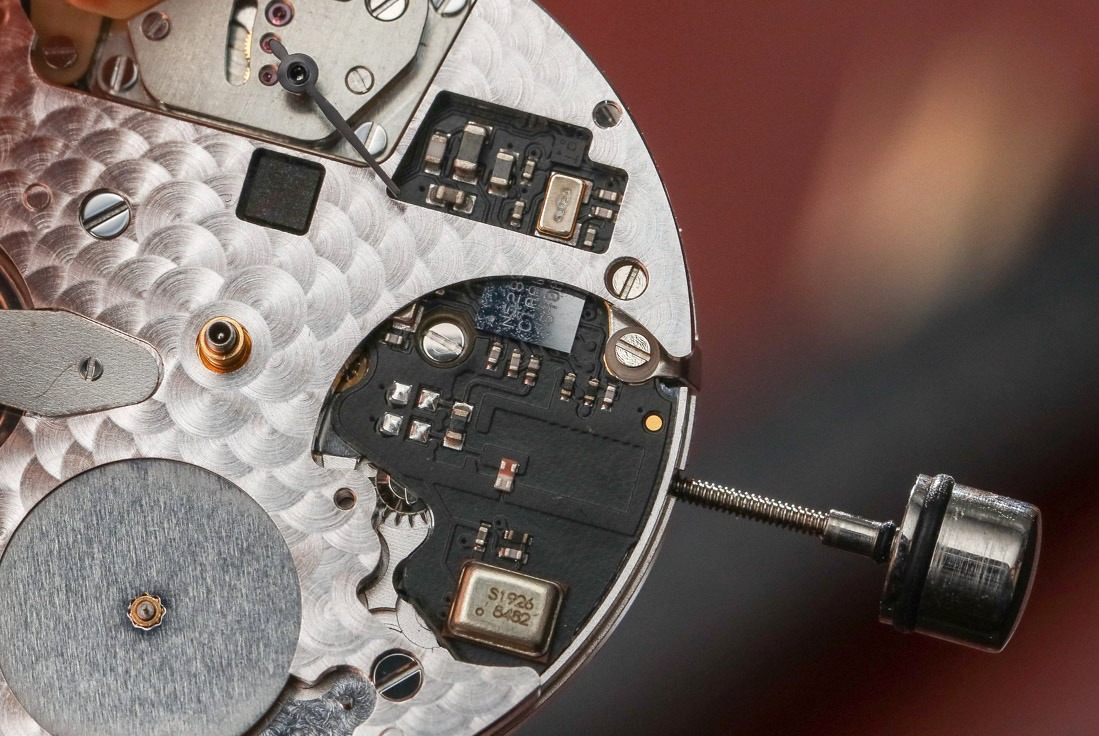

aBlogtoWatch has covered some of the recent regulatory changes related to Swiss Made over the years. For instance, in 2017, the Swiss Government changed the relevant laws to make “Swiss Made” be 10% more Swiss. Around the same time, I published an editorial that helped explain Swiss Made and the culture around it in Switzerland. Switzerland had pressure from watch companies to strengthen the term because some players felt it was too easy for “Swiss Made” to be earned. How a given watch satisfies the “Swiss Made” standard is remarkably fuzzy. The law stipulates that a Swiss Made watch has a Swiss movement and is cased up and inspected in Switzerland. OK, so what makes a watch movement Swiss? Good question. In addition to a movement needing to be assembled (put together) and inspected (final check) in Switzerland, a Swiss movement has 60% of its essential value coming from Switzerland. Most people assume that this latter requirement means 60% of the monetary value of the movement comes from Switzerland, but in reality, the application of it gets fuzzy. For example, watch movements have one or just a few parts which they say account for 60% of a movement’s value, and that those parts are produced in Switzerland.

“Swiss Made” allows for two primary mechanisms for Swiss Made watches to not be very Swiss at all. First is that most of the parts of a Swiss movement, and ALL of the parts of a case, dial, hands, bracelet, etc., do not need to be manufactured in Switzerland. Second, even though assembly and checks of the watches and the movements needs to be done in Switzerland, they don’t need to be done by Swiss citizens.

The biggest critics of the Swiss Made standard are those Swiss watch brands whose “Made in Switzerland” watches vastly exceed the minimum requirements of Swiss Made. Their watches tend to be much more expensive because Swiss labor and Swiss manufacturing are much more expensive. Brands whose products are much more “Swiss” lament that the Swiss Made label can be applied despite heavy reliance on outsourcing and foreign labor.

The same mechanism many “Swiss Made” watchmakers have been using to keep production and manufacturing costs low might now cost them dearly — in some instances causing manufacturing to stop entirely. It also isn’t clear who might save them. Beyond the more serious effects of the COVID-19 pandemic, it exposed a deep and prolific reliance on China, both for manufacturing and for consumption. This reliance now means many watchmakers in Switzerland aren’t just having a problem selling their watches but also a problem producing them in the first place. More on this topic below.

In an entirely different way, COVID-19 also threatens core labor markets, which Swiss watchmakers rely on to produce Swiss Made products. The majority of watch manufactures in Switzerland are placed along the borders with neighboring countries. While these watch factories do indeed employ Swiss people, a number of their technical staff are non-Swiss hired from across borders. Swiss watchmakers get to enjoy lower manufacturing costs with less expensive labor, and the workers still get better paying jobs than what might be available on their side of the border.

Southern Switzerland, where Italian is the primary language, borders the North Italian border. At this time, the North Italian border is on lock-down due to a self-imposed quarantine set by the Italian government as a means of stalling the spread of the COVID-19 virus. This quarantine is blocking a huge portion of the labor base that is employed to staff Swiss watchmakers in the area — a serious hub of manufacturing output. Reliance on a resource outside of Switzerland has rendered the production of “Swiss Made” watches impossible for a disturbing number of companies.

Returning to the discussion of over-reliance on single manufacturing zone, another major issue is that a number of Swiss Made watches cannot be assembled due to a lack of parts. The Swiss Made rules allow for all of a watch exterior and much of the movement to be manufactured elsewhere. There is nothing wrong with this, in theory, but the strategy is dependent on diversification to actually protect Swiss watch manufacturing stability. Switzerland, like a number of countries and industries around the world, have over-relied on specifically China as a manufacturing base. There is nothing wrong with getting your watch parts made in China, but the COVID-19 virus has forced closure of many factories and created a vacuum for parts. What COVID-19 did in slowing down watch manufacturing in Switzerland was demonstrate how too many brands put all their eggs in one basket by relying on China exclusively for parts. A sounder strategy would be to have multiple manufacturing partners around the world. “Swiss Made” as applied was supposed to give a number of enterprising watchmakers the flexibility to be global powerhouse businesses, but today’s situation is seen by many to suggest that watchmakers have taken advantage of the loose regulations and become complacent by relying on a single foreign manufacturing partner. Can actual Swiss industry pick up the slack?

The incredible irony of Swiss Made’s weak state of affairs is that it is not from consumer backlash or volatility in quality. “Swiss Made” is suffering because, as a loosely Swiss standard, Switzerland may be unable to ship many Swiss watches due a lack of foreign resources, a fact the self-sufficiency-minded country can’t be proud of.

Is the answer to Swiss Made to make it more Swiss Made? Many in Switzerland lament the loss of manufacturing jobs and businesses to foreign countries and foreign workers. it is a common story around the world. Should “Swiss Made,” as a term, be designed to bring back more watch industry jobs to Switzerland?

In the 1980s and 1990s, when the Swiss watch industry moved almost entirely upmarket, they justified higher prices because of the related lower manufacturing output, higher quality, and more exclusivity and prestige inherent in the product. Applying contemporary principles of luxury brand marketing, the agreement with the consumer was that “Swiss Made” necessarily meant more expensive because a “Swiss Made” customer was seeking more than just an instrument to tell the time. For at least two decades, the bargain worked, as the majority of the Swiss watch industry entered the arena of luxury, not utilitarian brands.

In 2020, Switzerland might need to do the same thing over again. Corporate interest in luxury watches has put pressure on watchmakers to cut costs and improve margins. It’s arguably made the industry too reliant on foreign labor in a culture of risk intolerance and catering to the interests of absentee shareholders. For Switzerland to get Swiss Made’s mojo back, perhaps it also needs a healthy dosage of authentic Swiss culture, something many argue has been a missing ingredient from many Swiss watches.

The more “Swiss” Swiss Made is, the more expensive the products might need to become — at least in the near term. While the COVID-19 pandemic will hopefully pass in the coming months, the state of the watch industry when it happens has yet to be seen. Will Swiss watch brands be able to cope with potentially months of inadequate parts and labor? How many will perish as a result? Will Swiss-based manufacturing be able to pick up where foreign manufacturing has left off?

Those with little to lose in such above-mentioned shakeups decry that all of this is a blessing in disguise. They say that the Swiss watch industry has been too complacent for too long, ignoring an obviously changing world around them. If “Swiss Made” is to be fixed, they say, it will not be by volunteers, rather, by hands forced by the market. An inability for Swiss-based watchmakers to produce watches will have the result of forcing at least a few of them to find solutions. While some companies will perish, the remaining ones will likely be more agile and ready for doing business in the future.

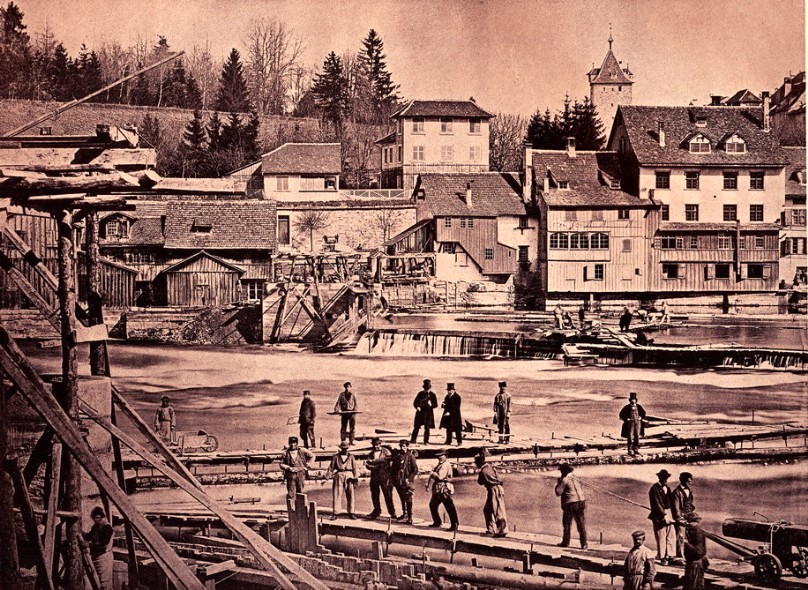

The last few years in the watch enthusiast space has seen the launch of countless small “collector’s brands.” At the same time, enough of the big players in the space have been busy tripping on their own feet. Already, as the old growth of the forest succumbs to flames, fresh saplings emerge on the forest floor, eager for their chance to reach the canopy. I detail this sentiment because some argue that the traditional watch industry is in peril (a story the Swiss have been concerned about since the end of the 19th century). I argue that it isn’t. Even if some of the names we associate with Swiss watches aren’t here tomorrow, I firmly believe that, if the industry is supportive of entrepreneurship and creativity in Switzerland, then “Swiss Made” can be trusted to save itself.