While strolling the pastoral English countryside of Cornwall in 1791, the amateur geologist Reverend William Gregor happened upon black, magnetic sand that he christened with the innocuous name mannacan to honor his small parish. Little did he know that in two short centuries, the metal in those sands — later renamed titanium in homage to the Greek deities sired by Uranus and Gaea, a title certainly more befitting its stature — would become instrumental for creating everything from artificial joints to military aircraft to parts for NASA’s Mars Curiosity Rover. Citizen was the first watch brand to see the potential in titanium, creating the world’s first titanium watch in 1970, the Citizen X-8 Chronometer. But that was just the start; over the past 50 years, Citizen has been at the forefront of innovation in using titanium in watchmaking.

As a metal, titanium has a number of properties that make it ideally suited for a wide range of applications — it’s incredibly strong, lightweight, non-toxic, and corrosion-resistant. For watches, this makes for an ideal case material. At only 60% the weight of stainless steel, titanium watches wear extremely comfortably without sacrificing any of the strength of steel. For people who suffer from nickel allergies (one of the components in most stainless steels), the fact that titanium is hypoallergenic makes it instantly appealing. Being corrosion-resistant, titanium is a natural choice for divers.

Pure titanium, though lightweight, is relatively soft and is often alloyed with vanadium, aluminum, and iron to create a stronger, harder material (e.g., grade 5 titanium). However, as remarkable as grade 5 titanium is, it does show scratches relatively easily. Citizen knew that there was room for improvement and, in 2000, 30 years after the release of the X-8, it introduced the world to Super Titanium with the release of the Citizen ASPEC World Time. The introduction of Super Titanium to Citizen’s lineup marked a turning point for the brand, bringing years of quiet research and engineering to fruition and revealing Citizen as a world leader in the development of not only movement technology, but also material innovation.

Super Titanium combines Citizen’s proprietary titanium processing techniques with its extremely scratch-resistant Duratect surface-hardening technology. In other words, Citizen took the best of properties of titanium and improved them through advanced processing techniques and the addition of surface hardening that is roughly five times harder than stainless steel and highly resistant to scratches. The result is a case material ideal for watches that are designed for hard use and made to be worn day-in and day-out. However, Super Titanium hides another surprise: The Duratect treatment allows Citizen to create watches in a wide variety of colors, including silver, black, gold, and pink gold, just as a start.

To celebrate 50 years of titanium watchmaking innovation, Citizen recently unveiled its flagship Super Titanium watch, the 50th Anniversary Limited-Model Satellite Wave GPS F950 CC4025-82E ($5,000 USD) along with a new line of Super Titanium Armor timepieces ($550-650 USD). With a limited worldwide release of just 550 pieces, the Satellite Wave GPS F950 showcases cutting-edge materials and technology developed by Citizen over the past five decades. Sitting at 47.5mm in diameter, the F950 makes a bold statement on the wrist, with contrasting textures, finishing, and colors made possible by the use of Duratect. The case features “Sakura” pink gold-tone that plays off the deep anthracite of the bracelet and bezel. The bracelet itself is especially notable, being constructed to give the appearance of one-piece, pyramidal links. The angular elements of the bracelet result in a look that is masculine and elegant but, most importantly, wears comfortably on the wrist.

The use of vanguard technology in the Satellite Wave GPS F950 doesn’t end at the case. A quick glance at the dial reveals the myriad functions made possible by the Cal. F950 movement, including hours, minutes, world time, 1/20th second chronograph measuring up to 24 hours, countdown timer, flyback, and a power reserve indicator. The Cal. F950 movement provides accuracy of ±5 seconds per month even without time signal reception from GPS but, more importantly, the Satellite Wave GPS functionality means that the watch is able to receive signals from satellites orbiting the earth, allowing the watch to sync to your position and adjust to 40 time zones across the globe, ensuring the correct time no matter where your travels take you. Coupled with Citizen’s famous Eco-Drive movement that uses solar charging from any light source, the Satellite Wave GPS F950 will run for up to five years on a full charge. The watch also sports a sapphire crystal and 100M water resistance, making the Satellite Wave GPS F950 an elegant — and uncompromisingly functional — timepiece. For a more in-depth look at the Satellite Wave GPS F950, be sure to check out Ariel’s hands-on review.

While the Satellite Wave GPS F950 showcases Citizen’s technical prowess and its ability to execute to the highest standards, affordability is one of the key foundations upon which Citizen built its reputation and three new, accessible models have just been released in the Citizen Super Titanium Armor collection. Like the Satellite Wave GPS F950, the new Super Titanium Armor collection features Super Titanium case and bracelet and is powered by Citizen’s solar-powered Eco-Drive movement. The Armor designation aptly describes the watch both functionally, due to the use of Super Titanium, and aesthetically, as the new watches evoke the feel of modern armor plating. The new models are available in a clean, 41mm time-and-date model (AW1660-51H) or a 44mm chronograph in anthracite gray with either steel/white dial accents (CA7050-57H) or gold dial accents (CA7058-55E).

In developing Super Titanium, it was clear to Citizen that the material had clear applications outside the realm of watches. In 2019, Citizen partnered with Japanese startup iSpace to provide Super Titanium technology for use in its HAKUTO-R lunar exploration program. The goal of the program is to ultimately extend our human presence into outer space, beginning with two lunar missions planned over the next three years. Citizen’s Super Titanium will be used in a lunar lander and lunar rover set to explore the moon’s surface. If successful, this will be a world’s first for a private company.

Clearly, Citizen has been pioneers in the development and application of titanium in watchmaking and beyond. However, it’s the scientists and engineers that have spent decades making this possible. To provide a first-hand perspective on Citizen’s development of new technology, we spoke with one of the lead engineers in charge of materials development at Citizen, Mr. Seiichi Hiroe.

An interview with Citizen’s Seiichi Hiroe

Since 1983, Mr. Seiichi Hiroe, Key Engineer of the Manufacturing Technology Division, has played an instrumental role at Citizen, pushing what is possible with material science. Mr. Hiroe began his career at Citizen working in precision processing, before moving on to developing case materials and eventually leading the development of Super Titanium.

How does Citizen’s Super Titanium compare to the more common grade 2 or grade 5 titanium used in watchmaking?

Mr. Hiroe: Titanium itself is a material that is soft and difficult to process, and it has a weak point that it is easily scratched. Citizen’s “Super Titanium” is our unique material made by processing titanium and treating it with our proprietary surface-hardening technology, Duratect. The materials we are adopting for Super Titanium are carefully selected, and we are particular about the size of the crystal grains mainly to achieve the beautiful, smooth mirror-finishes of Duratect. Vickers hardness is one of the indicators of hardness. The Vickers hardness of the surface of Grade 2 material is about 160. The Vickers hardness value of the surface of the grade 5 material as it is about 320. By applying our surface-hardening technology, “Duratect,” Super Titanium has Vickers hardness of 1000 or more, and this value is more than 6 times harder than regular titanium and stainless steel, which enable its scratch resistance to protect your watch from the daily scratches.

Our Super Titanium is a unique material that is scratch-resistant, light-weight, skin-friendly, and rust-resistant due to our unique processing technology and surface hardening technology. It was in 1970 that we adopted titanium for watch case materials for the first time in the world, but for the next 50 years, we continuously learned about titanium and continued to develop processing methods and surface-hardening methods. Even now, we are continuing the research and development, taking over the achievements of senior engineers.

How do you go about creating unique case shapes from and finishes with Super Titanium?

Mr. Hiroe: Titanium is not strong at the stage of processing the material into the case shape. Rather, titanium is originally soft and hard to process and is easily scratched. We are continuously developing the proper methods and know-how to be applied to each manufacturing process of watch cases with vast knowledge and experience towards the titanium properties.

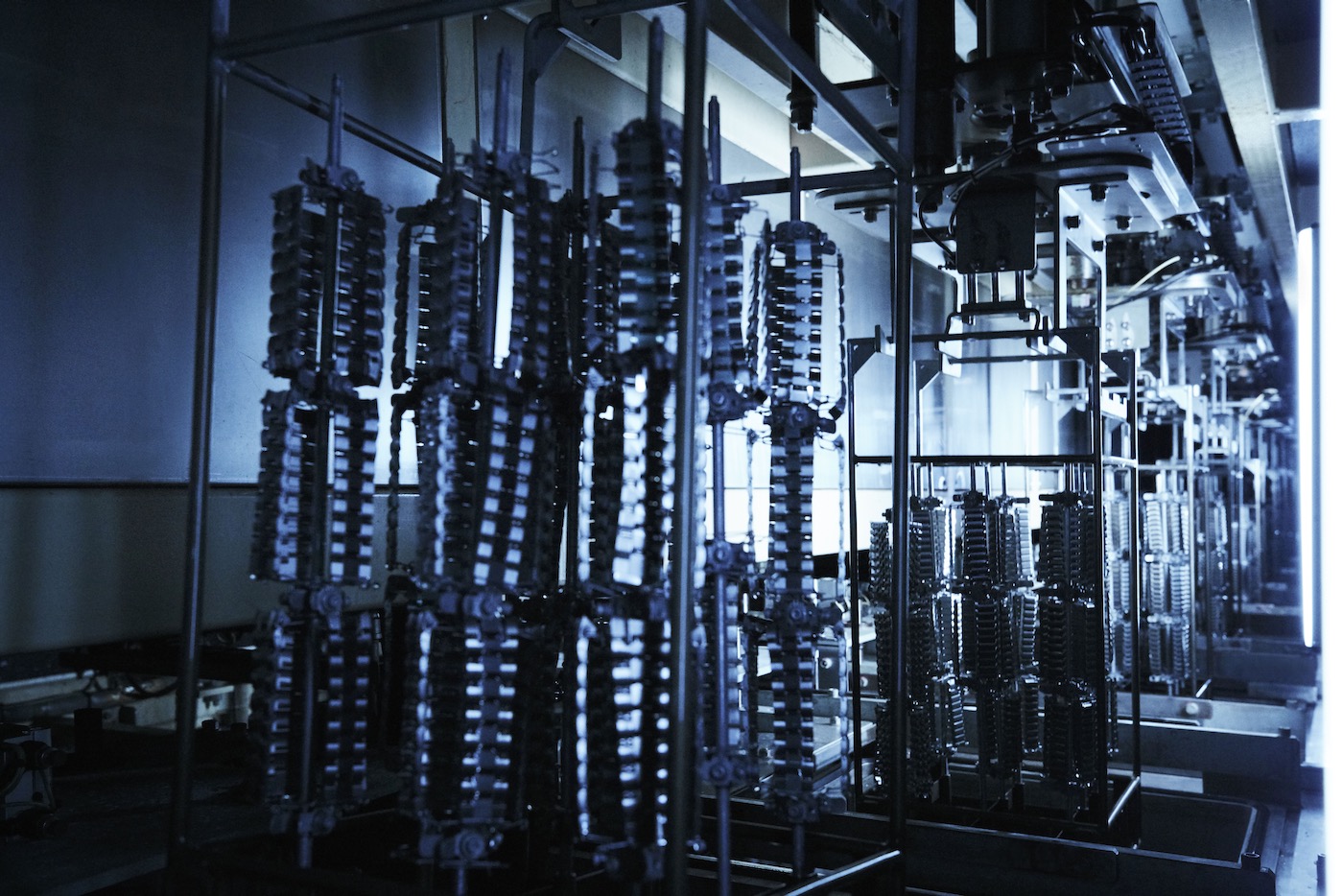

The outline of case manufacturing is: material selection ⇒ pressing ⇒ machining ⇒ polishing ⇒ surface hardening.

Super Titanium technology allows us to create a beautifully unique case shape with many surfaces with edgy, straight lines while having nicely polished mirror-finishes that are features of Super Titanium watches.

How long did the Research and Development phase take to create the version of Super Titanium we see today? Were many other processes attempted and rejected?

Mr. Hiroe: In 1970, we launched the world’s first titanium case watch, and we released the prototype of what is now known as Super Titanium in 2000. Titanium as a material easily reacts with oxygen and nitrogen, and it adhered to the mold during press molding, and titanium chips scraped the cutting edge of the drill during cutting. Titanium filings are also highly combustible which is another issue to the engineers. Finally, we made the 1970 X-8 chronometer by overcoming those hardships; however, there was still room for improvement to be beautifully shaped and finished while the color was still dull. After intense studies and improvement for surface appearances and boosting its hardness, the Super Titanium technology was created, which is a result of Citizen’s continuous research and development with titanium material for more than 50 years. We are sure our challenge still goes on.

From the engineer’s perspective, we assume the theory in itself is crucial; however, the trial and error through the research and development work is essential, and we made it a rule to put a high priority on experimental results, which enable us to get closer to the ideal theory. There are many mistakes that we made; however, we tend not to think of them as failures. Instead, we regard them as good samples to study and analyze for further improvements.

What is the biggest challenge in creating a new case material?

Mr. Hiroe: In order to create new things, I think that tenacity and a challenging spirit are required not to give up easily because we are trying to create something new that has never existed in the world or something that nobody has achieved. We are proud that we keep being highly motivated by sharing this mindset.

A major element that makes Super Titanium possible is the incorporation of Duratect. Can you tell us how Duratect works? How does Duratect compare to other hardening processes, like Seiko’s DiaShield, Sinn’s Tegiment, or Damasko’s ice-hardening?

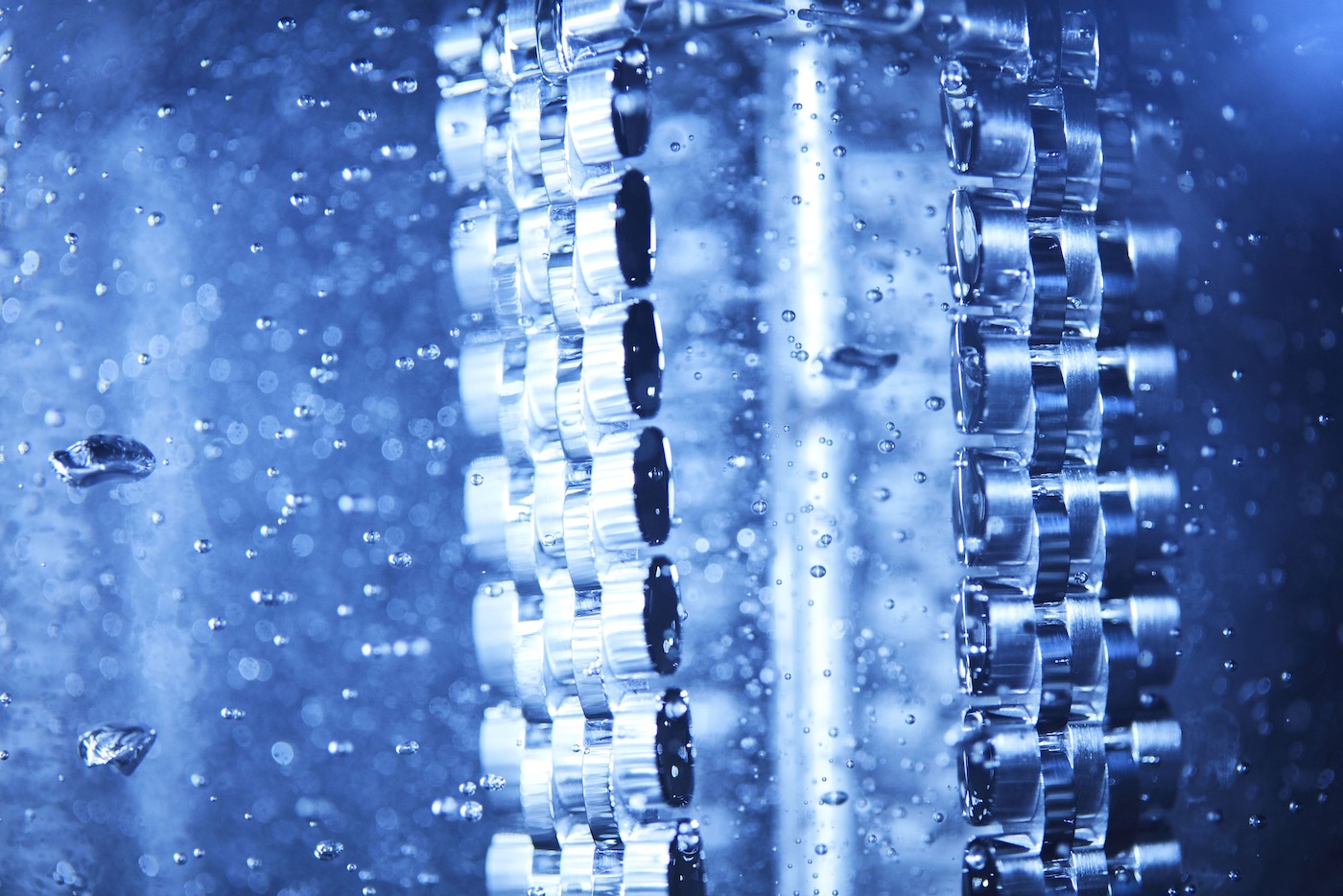

Mr. Hiroe: Duratect is to protect the wristwatch from scratches from everyday life, and it enables us to expand the titanium-made product lineup with beautiful color variations. Duratect consists of two technologies. One is the technology that hardens the surface by forming a hard thin coating on the surface of the material. The other is the technology that makes the material itself harder by boosting its surface density. We use it alone or in combination.

In terms of watchmaking, what does the use of Super Titanium allow Citizen to now accomplish that would otherwise have been impossible?

Mr. Hiroe: I think that the role we played in the watch industry with Super Titanium was to find out the potential of titanium as a new option for the wristwatches and made a new trend as a leading pioneer. In addition, by using titanium as the hypoallergenic material for the wristwatch case, we are proud to be able to offer user-friendly comfortable watches for those who are suffering from skin problems.

What’s next for Citizen? Is Super Titanium the pinnacle of titanium or do you think there’s still room to explore the material?

Mr. Hiroe: I am afraid we are not able to disclose the details, but the development of Super Titanium and Duratect is still ongoing, and it is not completed. This is reflected by our brand philosophy “Better Starts Now.” That is the simple belief that it is always possible to make something better and that now is the time to start doing it. According to this belief, we will continue to take on challenges in Super Titanium and Duratect.

Can you tell us a bit more about how Super Titanium is being used for space exploration?

Mr. Hiroe: Last March, CITIZEN delivered iSpace prototype parts made of Super TitaniumTM that will be used for the legs of the HAKUTO-R lunar lander. Light and strong materials are required for the landing legs to withstand the impact of landing on the moon. Furthermore, since the rotating shaft and connecting parts are moving, not only hardness but also smoothness is required. The surface-hardening technology “Duratect DLC” is not only resistant to scratches but also has a very smooth surface. The surface is hard to peel off and has excellent durability. In addition to strength, we have also been particular about the beauty of the material used for wristwatches. Therefore, it is judged that the unique titanium processing technology can be applied to spacecraft in terms of lightness, strength, and smooth material with little friction. This time, we have completed a prototype of a lander part.

To learn more about Citizen’s Super Titanium and their new watches, be sure to check out the brand’s website.

Sponsored Posts are a form of advertising that allows sponsors to share useful news, messages, and offers to aBlogtoWatch readers in a way traditional display advertising is often not best suited to. All Sponsored Posts are subject to editorial guidelines with the intent that they offer readers useful news, promotions, or stories. The viewpoints and opinions expressed in Sponsored Posts are those of the advertiser and not necessarily those of aBlogtoWatch or its writers.

Podcast: Play in new window | Download