Sponsored post presented on aBlogtoWatch for advertiser

Sponsored post presented on aBlogtoWatch for advertiser

Titanium is more prominent in the current watch industry than ever before, with brands across the marketplace turning to the metal as a lighter, more durable, and more visually aggressive alternative to traditional stainless steel. Despite its current prevalence and the material’s ultra-modern reputation, titanium is far from a new development in watchmaking, and no brand understands this material better than Citizen. Citizen introduced the world’s first titanium watch, the X-8 Chronometer, all the way back in 1970, and the Japanese giant has spent more than half a century refining and perfecting titanium in watchmaking. The result of this dedication and constant innovation is Super Titanium, Citizen’s proprietary material that offers a broad range of benefits no other manufacturer can match.

Super Titanium’s revolutionary properties can be laid at the feet of two important breakthroughs by Citizen. The first of these is Citizen’s unique titanium processing methods. Although it comes with many material benefits, titanium is notoriously difficult to work with for several reasons. The hardness that makes titanium so resilient also makes machining titanium a slow and wear-inducing process for most factory equipment, but the nuances of titanium processing go deeper. Beyond the obvious hardness of the metal, machining titanium also tends to create chemically active filings, which attach to drill bits and break equipment at an accelerated rate. Surprisingly, titanium itself is also soft and sticky. It may not be adhesive in the same way as glue, but because raw titanium tends to react with atmospheric oxygen and nitrogen, when put through an industrial press, titanium can bond with the base metal of a press mold and become difficult to remove, which can lead to serious structural deformation. Also, polishing titanium requires special procedures because of the metal’s crystallite structure. Even if a manufacturer uses a sufficiently strong polish to break through titanium’s hardness, using traditional polishing methods will lead to an uneven, “orange peel” surface. Instead, Citizen uses a careful mix of polishing methods to overcome the unique difficulties of the metal and create a beautiful shine. Through its decades of experience and research in manufacturing titanium cases, Citizen has developed proprietary technologies for each of these manufacturing problems.

The other half of Super Titanium’s unique strengths comes from Citizen’s unique Duratect surface hardening technology. As many enthusiasts know, raw titanium is an excellent metal. However its hardness is lower than that of stainless steel, so even when polished to a beautiful mirror-like surface, it is surprisingly easy to scratch and loses its luster. Duratect solves the problem elegantly. Thanks to Duratect, Citizen can produce brilliantly polished titanium watches with immense scratch resistance. Duratect-treated titanium is fully five times more scratch-proof than stainless steel. In addition, Duratect-treated titanium can be imbued with a variety of different color tones that are impossible to achieve with untreated titanium. Duratect is also a versatile process – depending on the unique material needs of each watch model, Citizen uses processes to coat the base titanium material, make the actual titanium surface itself harder, or both. One of Citizen’s flagship techniques used for Duratect technology is referred to as Duratect MRK, first patented by the brand in 1997. Through a combination of gas treatment, vacuum exposure, and high-intensity heating Duratect MRK hardens the surface of the titanium itself at a depth dozens of times thicker than a traditional hard surface coating.

The benefits of this intensive Super Titanium material system speak for themselves. Not only does Super Titanium carry all the material benefits of untreated titanium, including weighing 40 percent less than stainless steel, being nearly impervious to corrosion, and being totally hypoallergenic, this unique material also carries virtually none of titanium’s shortcomings. Super Titanium offers world-class scratch resistance, can be made in a vibrant spectrum of tones and colors, and can be polished to a brilliant mirror shine. The material is so effective, Citizen has even provided Super Titanium components for the HAKUTO-R commercial lunar exploration program.

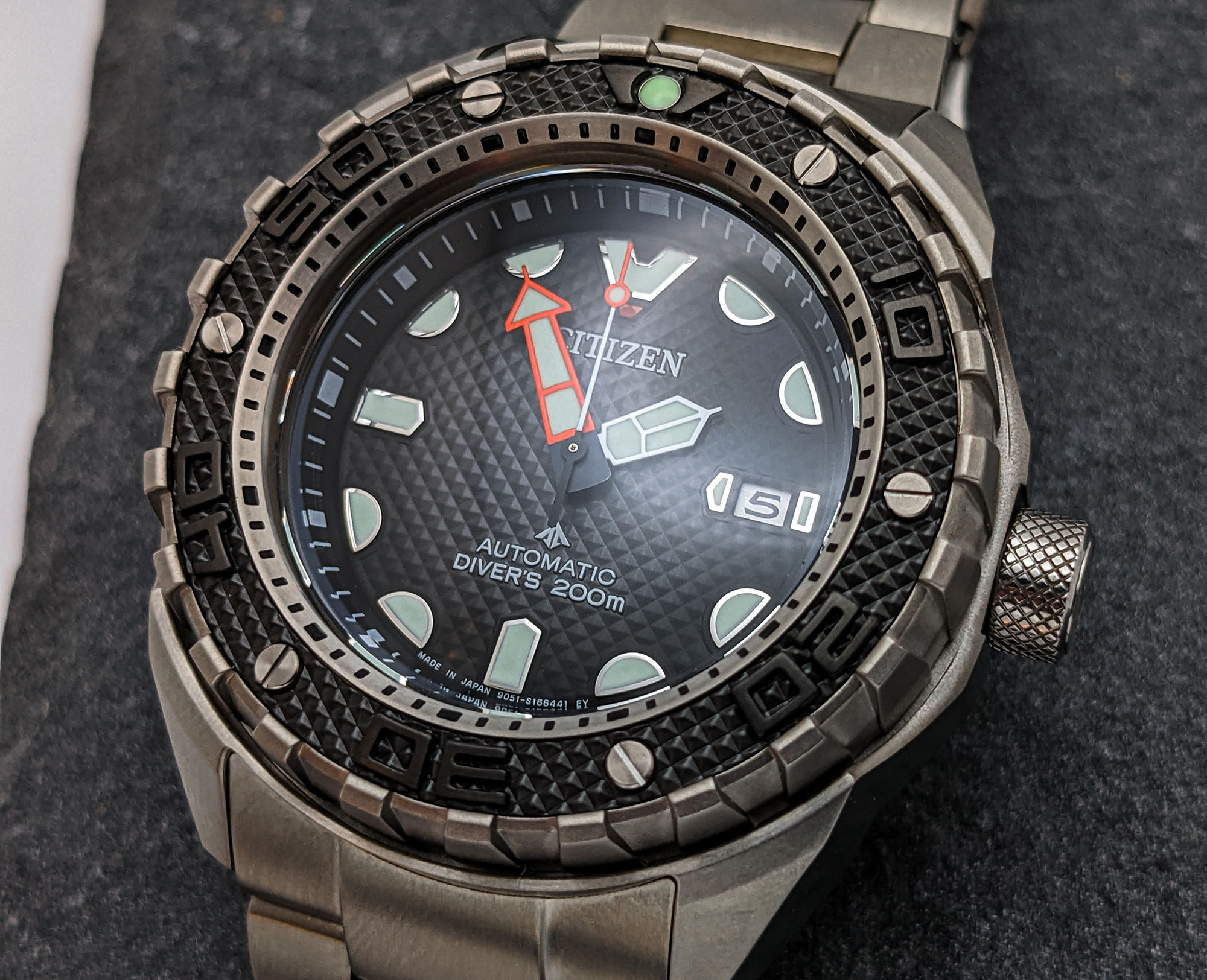

Closer to Earth, Super Titanium’s mix of material strength and aesthetic beauty can be seen throughout Citizen’s product lineup, particularly in sporting models like the Citizen Promaster Dive Automatic 200M NB6004-83E pictured here (view a full review of this model here on aBlogtoWatch). Not only does the Super Titanium case, bezel, and bracelet exude rugged dive-ready style, the material’s unique blend of properties make it a perfect fit for the high-impact, potentially chaotic, and surprisingly corrosive world of deep-sea diving.

At a time when titanium is more popular than ever among watch enthusiasts, Citizen continues to prove that the first-ever brand to make a titanium timepiece still knows the material best. With its innovative Super Titanium material, Citizen creates designs that consistently outperform the competition both technically and visually. To learn more about Citizen’s lineup of watches made from Super Titanium, please visit the brand’s website.

Sponsored Posts are a form of advertising that allows sponsors to share useful news, messages, and offers to aBlogtoWatch readers in a way traditional display advertising is often not best suited to. All Sponsored Posts are subject to editorial guidelines with the intent that they offer readers useful news, promotions, or stories. The viewpoints and opinions expressed in Sponsored Posts are those of the advertiser and not necessarily those of aBlogtoWatch or its writers.