At the heart of each timepiece is a movement. It is an engine whose development has been continuously improved upon since the 16th century. Literally, hundreds of years of human skill and innovation are contained in modern-day mechanical movements, while most timepieces sold to mainstream consumers are, in fact, more like appliances and tools that have efficient, electronic mechanisms in them. Mechanical watches on the other hand are for people who can’t help but love a well-made machine.

Only a small number of companies around the world have the ability to manufacture or assemble mechanical movements, and still fewer have the ability to design them from nearly the ground up. THE+ and the watch brand Horage that it was developed from, represent just such a rare company. The THE+ is headquarters in the Swiss city of Bienne/Biel, a split name because it rests on an intersection between German and French-speaking Switzerland. It is also home to many of the world’s old names in Swiss watchmaking. It is where Rolex produces its movements and where much of the Swatch Group is headquartered.

More than a decade ago now, the same Swatch Group announced intentions for its in-group watch movement maker ETA to cease selling movements to a number of brands. At the time, ETA was one of very, very few companies to produce Swiss Made mechanical movements that it would sell to companies who could put them in their own products. ETA didn’t want to supply as many brands as it was, and the Swatch Group and the Swiss government are still today debating the actual terms of what ETA’s duties to the marketplace actually are.

In any event, for quite some time ETA did stop selling so many movements to brands outside of the Swatch Group and concurrently called upon the Swiss watch industry to invest in new and innovative companies that can make movements. This is precisely what happened — and THE+ is just such a company. What THE+ is not is one of many companies whose answer to ETA’s call to action was to simply copy ETA movements. Legally, patent or other protections on ETA mechanical movements have long since expired. While ETA continued to develop fresh technology, its mainstay movements used in a large number of globally available wristwatch movements could now be legally copied by anyone who tried hard enough to replicate them. This aforementioned approach as help supply a lot of mechanical movements, but THE+ had a different idea. It wanted to not only offer an alternative to the ETA mechanical movement experience but also to offer one that was wholly distinctive — and at a competitive price point.

This latter point is crucial because, indeed, a large universe of available mechanical movements do exist out there, but not at price points that would allow them to sell for anything close to as low as what an ETA-equipped watch could go for. For example, if a watch movement alone costs $3,000 for a brand to purchase, at what price point must the final retail price be for that brand to earn the desired profit margin? The answer is quite high.

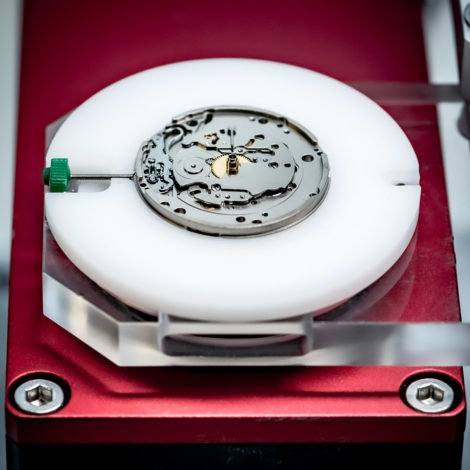

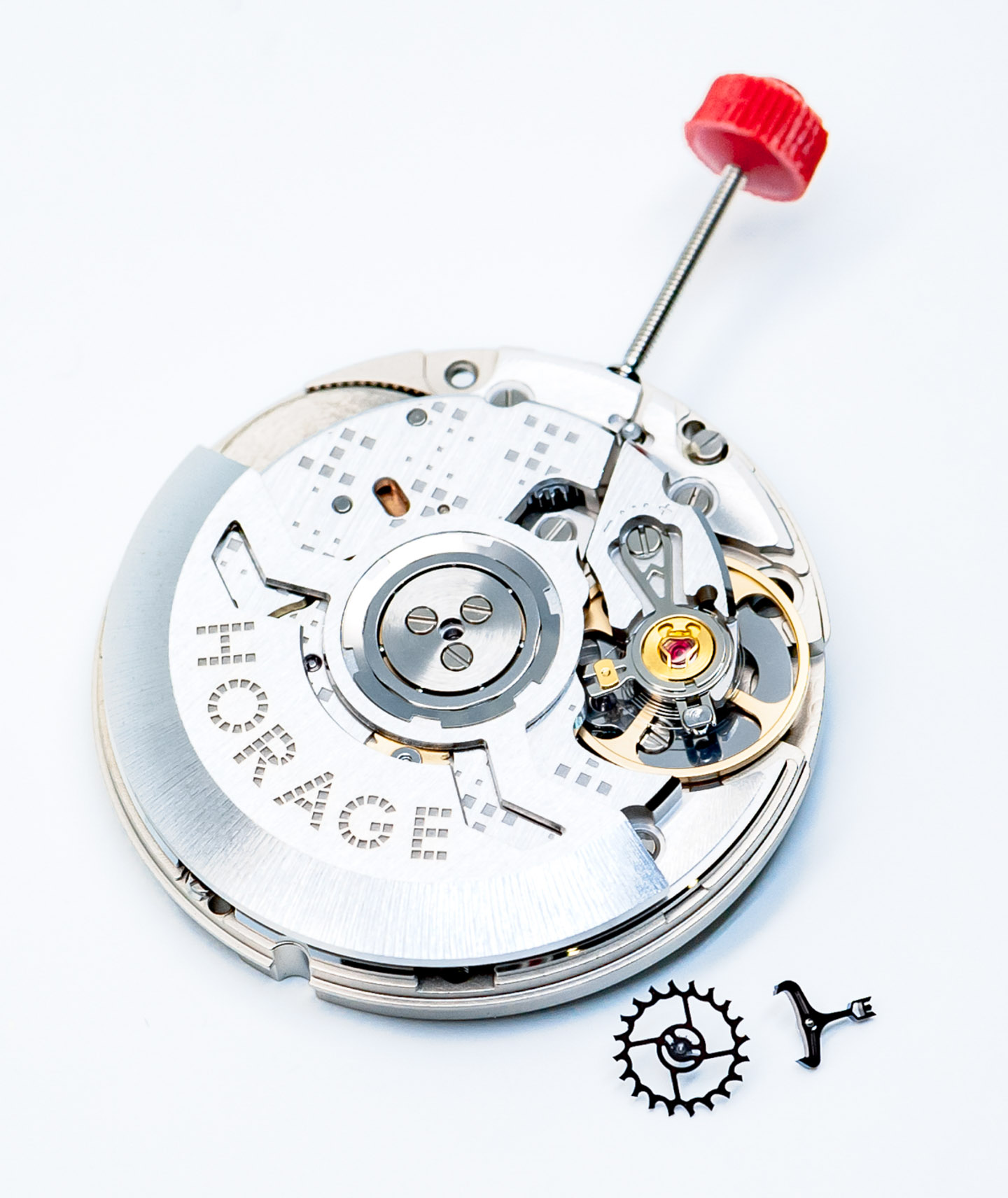

Watch brands not able or willing to produce their own Swiss Made movements, but that want a less-than-generic experience for consumers in a $5,000 USD and under product, do not at this time have too many options. THE+ and its in-house designers developed and made K1 automatic movement system, now a 10-year-old answer to that problem. The K1 automatic movement is both an original base Swiss Made automatic and a platform for a host of modules, which when placed over the base can modify or add to the core time-telling functions.

Horage watches mostly feature K1 automatic movements, with various modules that add features and complications. I’ve worn at least two watches with the K1 and found them to be really impressive. I certainly put the K1 up there as one of the most desirable Swiss Made movements at this price point. I also think that, with so many watches having used ETA and similar movements over the years, a lot of brands could benefit from the novelty and new artistic opportunities that something like the K1 can offer.

Now let’s hear from THE+ itself, namely K1 movement designer Jonas Nydegger. We rarely interview actual movement designers, so I hope you enjoy this deeper look in the Swiss Made THE+ K1 movement.

aBlogtoWatch (ABTW): Horage and the K1 movement already have a story to tell with over 10 years of history. Jonas Nydegger, you’ve been a pivotal individual in the foundation of the company. Tell us a little about your background and just how things came to be with Horage and the K1 movement?

Jonas Nydegger (JN): I am fascinated by the development and production of mechanical objects. My drive is filed by an interest in technical production. In school, I studied watchmaking and apprenticed as a watchmaker. I later moved on to studying production engineering with a focus on watch movement construction, and later I studied system engineering. Over the past 15 years, I have met many fascinating craftsmen that inspired me to stay on this path. In my early years, I worked with companies on projects that implemented a lot of incorrect strategies and made costly operational mistakes. I learned a lot about what not to do, and these hard lessons helped me when I eventually ran projects of my own. Jumping ahead to K1, I was literally thrown into the deep end, as it was and is a massive movement project, but I knew how to navigate the pitfalls from previous experience.

The founders of Horage — Tzuyu and Andi — are two very open-minded and forward-thinking individuals and early on trusted me and let me take the lead with K1. In addition, Andi has challenged me to look further into the future and what modern watchmaking can look like. Tzuyu is the strategic mastermind behind THE+ our production firm and, aside from that, Tzuyu is also the best cook I have ever met — and I love to eat, so that makes me happy. I am appreciative of the opportunity Tzuyu has given me each and every day.

Tzuyu has shifted her focus to Horage brand-building and has given me the reins to the movement projects. We have an amazing young team, and we have a lot of fun making movements — things just keep getting better.

ABTW: How rare is it today for a watch brand (or any company for that matter) to build a movement from the ground up?

ABTW: How rare is it today for a watch brand (or any company for that matter) to build a movement from the ground up?

JN: Extremely rare. Just have a look at the market. The movement game is only set up for the big players to be a part of. There simply are not enough talented engineers on the market. Add in the cost of investment, and the risks are catastrophic. What we created with K1 is something very remarkable.

ABTW: Considering the extremely high cost barrier to entry, how easily can one access information and talent to see the project through to completion?

Making movements has three big variables at play; cost, talent, and time. Excellent engineering can reduce cost and decrease time to market by a few years, but finding a sound educated team willing to invest their time and their futures in such projects is an anomaly. The reason there is not more talent is that too many brands made too much money selling old technologies over the past 40 years and not investing in the future of watchmaking. No investment in future watchmaking means fewer apprentices being trained and, ultimately, the entrepreneurial spirit of an entire industry is left to die. Great movements take years to come to market, and there are few that have the balls to do something like K1.

ABTW: From the perspective of consumers, what is special about the K1 and why should they pay attention to it?

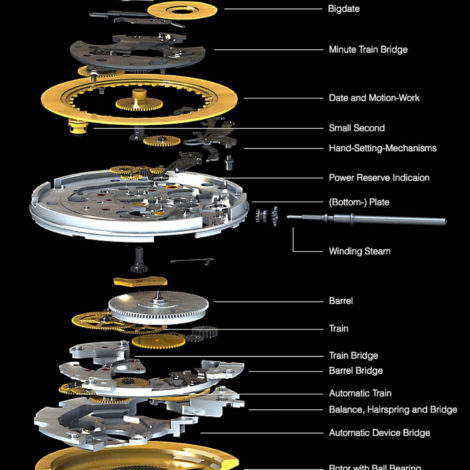

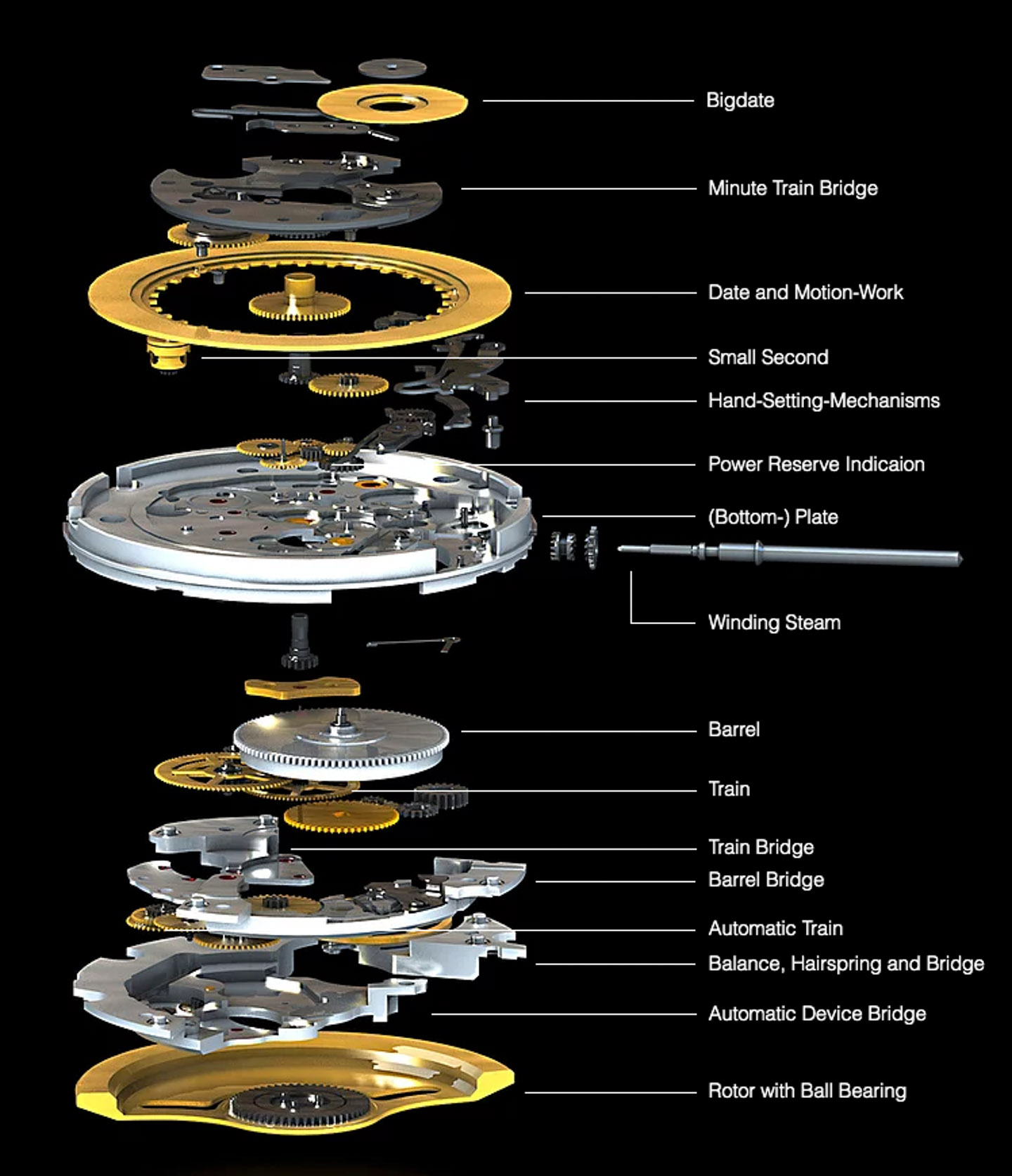

JN: K1 is a very interesting movement due to it being a first to have configurable modularity. Early on, we showed this modularity through various campaigns, and with our Multiply watch customers were able to configure the complications of their finished watch and still can today. The modularity of the design means it delivers a consistent dimension across all functions applied to it. This means that Horage, or any brand for that matter, can reduce stock, time to market, and be more agile in shifting production to markets demand on best-selling products. This means the work and financial investment becomes much easier for Horage to manage, and this brings a ton of value to the customer — better prices for increased quality as well as better spec’d watches leading to a more product diversification overall.

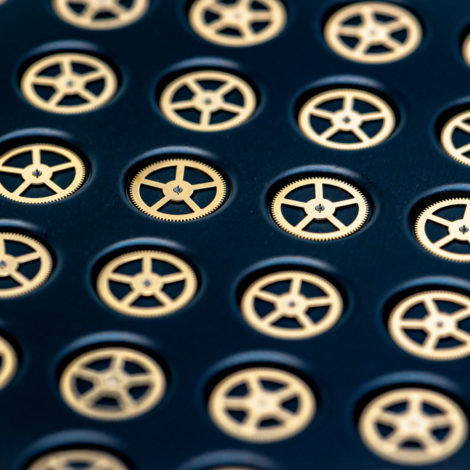

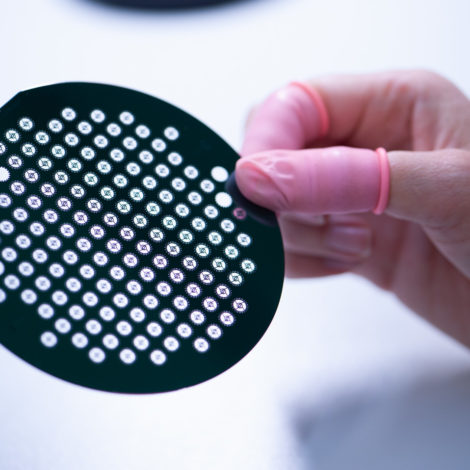

In the end, the brand is more flexible, reactive, and expedites product development time, and all this means customers get not only more value but also more of what they desire most. This means customers’ money can go into products they love rather than products a brand needs to market to make room for new stock. K1 is not a clone, but rather made from the ground up, in-house by us. It is built on the latest advancements in global production technologies such as more flexible production processes, new coating technologies, and new advancements in escapements like our silicon escapement that has a host of advantages, including anti-magnetism, increased power reserve, and fewer service intervals than traditional escapements.

ABTW: From a watchmaking performance perspective, how does the K1 movement compare to popular industry movements people known well?

JN: When it comes to performance, we have sound confidence comparing K1 with the latest and most advanced movements that are available on the market today, especially when one looks at the new generations coming to market from the big groups that have long power reserves as well as new escapement and hairspring technology. We achieve a comparable power reserve but deliver a more stable frequency of 3.5 Hz compared to hacked standard movements with a reduced frequency to 3 Hz.

Looking at one competitor’s newest movement that delivers around 70 hours of power reserve and is 5mm-high, on the surface it appears very close to K1; however, it is not modular and can only be spec’d to a standard three-hand and date complication. K1 can deliver much more with a big date, small second or center second, and power reserve indicator. Of course, there are other premium movement makers, but a premium movement comes at a premium price and is reserved for brands in the upper echelon of the luxury watch market. K1 has been designed to offer premium performance at a more digestible price point.

Service-wise, K1 is extremely stable, with modern construction, and the parts are easy to assemble, which means that should it need servicing the turnaround time is very fast. We recommend a service interval comparable with other industry-standard movements. However, we are confident that a run-time of up to 10 years is easily achieved before needing a full service inclusive of part lubrication.

ABTW: From a technical perspective what is interesting about the K1 in terms of architecture, materials, or construction?

JN: As relayed earlier, K1 is modular and this modularity brings efficiency, flexibility and lower cost to HORAGE and this inevitably leads to a greater value offer to the customer. K1 is a modern and compact movement. It is 25.6mm (11.5 lines) wide and 4.95mm high and this mean a multitude of watch sizes can be developed from a petite or small casual watch up to any size one would like. Currently the smallest possible watch we have is the 32mm Omnium and in such a size you can utilize every spec of K1.

From the early 1980’s until now there have been 3 standard movements produced by ETA, those being the 2892, 2824 and the 7750. The 2892 and 2824 are basic movements that offer a standard 3 hands and date. If a brand wanted to have a better spec like big date, power reserve indicator or others they would always have to buy a module to be assembled on top of the standard movements. This means that the movement is getting thicker and the watch case needs to change to accommodate this. However this is a costly exercise for a brand because for each and every spec, dial or face they need an entirely new case. That means a huge amount of case stock is needed to accommodate different movement specs. Planning for what the consumer is going to gravitate towards makes it nearly impossible to get the case stock correct and this means that if a product with a power reserve indicator is performing better than a 3 hand/date a brand cannot react quickly enough to the demand and then has to invest more heavily in marketing the dogs of the line. With our brand Horage we wanted to have this flexibility and felt others would appreciate such a movement.

K1 offers five specs that can be combined in 18 different face variations. This means all can be delivered within the same movement dimensions and that a brand needs only one case size per model for all model specs. Faster reaction to market demand can be achieved and the burden of inflated inventories can be avoided.

We looked to the car industry for our modular approach where such methodologies have been standard for decades. However, there simply has not been a lot of new movement development in the watch industry over the past 40 years and why such concepts are new to the watch industry and the watch enthusiast.

ABTW: From a watch brand perspective, what makes the K1 an attractive and affordable option for their upcoming timepiece project.

JN: The first point is availability and because Horage has K1 in-house it is available and doesn’t need to be sourced by a third party. Currently, there are extremely limited options on the market to brands looking for an up to date modern movement. If one wants to play in the same league as the big movement groups, then investing in the development of such a movement like K1 is needed. K1 is price-competitive with the new calibers coming to market from other makers. However, a comparison cannot be made to the basic shelf movements of yesterday that a brand can pick up for 70 Swiss francs. With new technologies and the desire for more precision and smaller movements, the cost of production of small-batch runs has dramatically increased. The sky is the limit when it comes to cost, however, the challenge is delivering a stable, modern movement at a competitive price — and this is something K1 delivers.

This price difference is seen in the final consumer price of products; many micro-brands are purchasing old technology that is easily obtainable and selling watches in the $500- $1500 range, depending on materials at play. With a K1 movement, the market entry could be as low as $1500 and then move up from there depending on what modular functions are utilized, what decoration is applied to the movement, and overall construction of the completed watch. Horage utilizes the very best materials available and has a start price of around $2,200 USD. There are many more costs that come in after the movement and materials, such as 904L stainless steel that is 8-10 times the cost of regular 316L, but the brand’s value statement starts with the movement.

Florian Serex, who has been a mentor to me, as well as a creative addition to the K1 project, was the one that saw the opportunity of combining the functions and decorations associated with a manufacture movement with the advantages of industrial reliability and scale. Thanks to his creative mind, forward-thinking and vast industrial knowledge, K1 is a hybrid of manufacture and industrial movement. Without him, K1 would not have seen the light of day. However, every fire needs a spark, and Stephan Kussmaul, the first engineer involved in the K1 project, birthed the idea of modularity — so their combined ideologies delivered a killer movement.

ABTW: There are a few other brands in the market turning out new calibers rather quickly, which makes one think that it might be easier than one thinks. How do these quick turn around calibers compare to what you are doing? How do these brands limit the invested time needed to bring a caliber to market?

JN: If a brand has an internal team and has gone through the development of a first movement, typically 7-10 years, and brought it to market, then it becomes easier to develop future movements. There is a ton of learning with a new movement, and the lessons learned can save a lot of time on crucial processes. However, this is a multi-year undertaking, and enough time must be taken to ensure stability. Brands should stick to one or two workhorses and limit their risk by not continually developing new movements. More movements mean less quantity per movement.

That leads to smaller batches which generate higher cost and less stable production quality. This is the line drawn when one compares a manufacture movement to an industrial movement. An industrial movement like K1 is designed for scale, performance, reliability, and cost reduction, but a manufacture movement means more new movements can be created in less time, but one sacrifices reliability, performance, and cost. We have taken the positive attributes of both manufacture and industrial movement and moved the needle a little further into the future.

Learn more at the Horage watches website here. Learn more about The Plus here.